H1: Exploring the Precision and Versatility of Wooden Laser Cut Gears

H2: Introduction

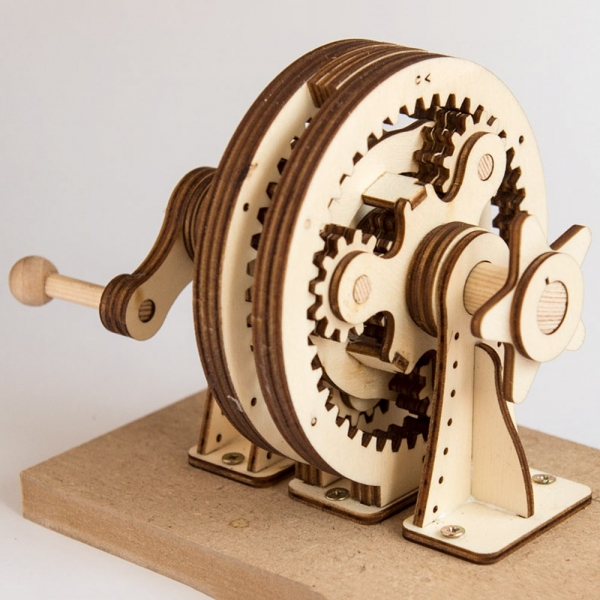

In the realm of mechanical engineering, precision and efficiency reign supreme. Laser cutting technology has emerged as a game-changer, enabling the creation of intricate components with unparalleled accuracy. Among these components, wooden laser cut gears stand out for their unique combination of strength, durability, and aesthetic appeal.

Table of Content

- 1 H1: Exploring the Precision and Versatility of Wooden Laser Cut Gears

- 1.1 H2: Introduction

- 1.2 H2: Advantages of Wooden Laser Cut Gears

- 1.2.1 H3: Strength and Durability

- 1.2.2 H3: Aesthetic Appeal

- 1.2.3 H3: Cost-Effectiveness

- 1.3 H2: Applications of Wooden Laser Cut Gears

- 1.3.4 H3: Industrial Machinery

- 1.4 H2: Advantages of Wooden Laser Cut Gears

- 1.4.5 H3: Precision and Accuracy

- 1.4.6 H3: Strength and Durability

- 1.4.7 H3: Robotics

- 1.4.8 H3: Decorative Objects

- 1.5 H2: Design Considerations for Wooden Laser Cut Gears

- 1.5.9 H3: Material Selection

- 1.5.10 H3: Tooth Profile and Geometry

- 1.5.11 H3: Laser Cutting Parameters

- 1.6 H2: Conclusion

- 1.7 H2: FAQs

- 1.7.12 H3: Are wooden gears as strong as metal gears?

- 1.7.13 H3: Can wooden gears be used in high-speed applications?

- 1.7.14 H3: How do I maintain wooden laser cut gears?

H2: Advantages of Wooden Laser Cut Gears

Laser cutting employs a focused beam of light to vaporize material, resulting in clean and precise cuts. This level of precision allows for the creation of gears with intricate tooth profiles and tight tolerances, ensuring smooth and efficient operation.

H3: Strength and Durability

Despite their lightweight nature, wooden gears are surprisingly strong and durable. The laser cutting process seals the edges of the wood, preventing moisture absorption and increasing resistance to wear and tear. This makes them suitable for applications where reliability and longevity are paramount.

H3: Aesthetic Appeal

Wooden laser cut gears offer an aesthetically pleasing alternative to metal gears. The natural grain and warm tones of wood add a touch of elegance to any project. They are particularly well-suited for decorative applications or where visual appeal is important.

H3: Cost-Effectiveness

DOWNLOAD SVG FILES FOR LASER CUTTING

Compared to metal gears, wooden laser cut gears are more cost-effective. This makes them an attractive option for prototyping, small-scale production, or hobbyists working on a budget.

H2: Applications of Wooden Laser Cut Gears

The versatility of wooden laser cut gears makes them suitable for a wide range of applications, including:

H3: Industrial Machinery

In the realm of mechanical engineering, precision and efficiency reign supreme. Laser cutting technology has emerged as a game-changer, enabling the creation of intricate components with unparalleled accuracy. Among these components, wooden laser cut gears stand out for their unique combination of strength, durability, and aesthetic appeal.

- Laser Cut Wooden Figures Laser Cut Wooden Figures: A Comprehensive Guide To Intricate And Personalized Creations

- Laser Cut Wooden Puzzles For Adults Laser Cut Wooden Puzzles For Adults: A Journey Into Intricate Beauty And Cognitive Stimulation

- Laser Cut Wooden Box Template Free H1: Laser Cut Wooden Box Template Free: Elevate Your Crafting Skills

- Wooden Laser Cut Ornaments Wooden Laser Cut Ornaments: A Timeless And Versatile Holiday Decoration

- Custom Cut Wood Pieces Custom Cut Wood Pieces: A Comprehensive Guide To Precision And Versatility

H2: Advantages of Wooden Laser Cut Gears

H3: Precision and Accuracy

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting employs a focused beam of light to vaporize material, resulting in clean and precise cuts. This level of precision allows for the creation of gears with intricate tooth profiles and tight tolerances, ensuring smooth and efficient operation.

H3: Strength and Durability

Despite their lightweight nature, wooden gears are surprisingly strong and durable. The laser cutting process seals the edges of the wood, preventing moisture absorption and increasing resistance to wear and tear. This makes them suitable for applications where reliability and longevity are paramount.

Wooden gears find use in various industrial machines, such as conveyors, packaging equipment, and textile machinery. Their precision and durability ensure smooth operation and extended lifespan.

H3: Robotics

The lightweight and low-friction properties of wooden gears make them ideal for robotics applications. They contribute to faster movement, increased accuracy, and reduced energy consumption.

H3: Decorative Objects

Wooden laser cut gears can be used to create stunning decorative objects, such as clocks, lamps, and sculptures. Their intricate designs and natural beauty add a touch of sophistication to any home or office.

H2: Design Considerations for Wooden Laser Cut Gears

H3: Material Selection

The type of wood used for laser cutting affects the strength, durability, and aesthetic appeal of the gears. Hardwoods like oak or maple are preferred for their superior strength, while softer woods like pine or basswood offer a more cost-effective option.

H3: Tooth Profile and Geometry

The tooth profile and geometry of the gears determine their efficiency and performance. Common tooth profiles include involute, cycloidal, and herringbone. The number of teeth, pitch, and pressure angle must be carefully selected to ensure smooth meshing and optimal power transmission.

H3: Laser Cutting Parameters

The laser cutting parameters, such as power, speed, and focal length, play a crucial role in the quality of the gears. Optimizing these parameters ensures clean cuts, precise tooth profiles, and minimal heat-affected zones.

H2: Conclusion

Wooden laser cut gears represent a unique blend of precision, durability, cost-effectiveness, and aesthetic appeal. Their versatility makes them suitable for a wide range of applications, from industrial machinery to decorative objects. By understanding the advantages, design considerations, and applications of wooden laser cut gears, engineers and hobbyists alike can harness their potential to create innovative and efficient solutions.

H2: FAQs

H3: Are wooden gears as strong as metal gears?

While wooden gears are not as strong as metal gears, they offer sufficient strength and durability for many applications. Their sealed edges enhance their resistance to moisture and wear.

H3: Can wooden gears be used in high-speed applications?

Yes, wooden gears can be used in high-speed applications, provided they are designed and manufactured with precision. The lightweight and low-friction properties of wood contribute to faster movement and reduced energy consumption.

H3: How do I maintain wooden laser cut gears?

Regular maintenance is essential to ensure the longevity of wooden laser cut gears. Keep them clean, lubricated, and protected from moisture. Avoid excessive loads or impacts that could damage the teeth or bearings.