Wooden Laser Cut Items: A Comprehensive Guide

Laser cutting has revolutionized the crafting industry, enabling the creation of intricate and precise designs on various materials. Among these materials, wood stands out for its versatility, durability, and aesthetic appeal. Wooden laser cut items have become increasingly popular for a wide range of applications, from home décor to personalized gifts and industrial products.

Understanding Laser Cutting Technology

Table of Content

- 1 Wooden Laser Cut Items: A Comprehensive Guide

- 1.1 Understanding Laser Cutting Technology

- 1.2 Applications of Wooden Laser Cut Items

- 1.3 Understanding Laser Cutting Technology

- 1.4 Advantages of Laser Cutting Wood

- 1.5 Design Considerations for Wooden Laser Cut Items

- 1.6 Tips for Optimizing Wooden Laser Cut Items

- 1.7 Conclusion

- 1.8 FAQs

Laser cutting is a precise manufacturing process that uses a focused laser beam to cut through materials. The laser beam is generated by a laser source and directed onto the material’s surface. The high-intensity beam vaporizes or melts the material, creating a clean and precise cut.

- Precision: Laser cutting offers exceptional precision, allowing for the creation of intricate and detailed designs.

- Speed: The laser beam’s high speed enables efficient and rapid production, reducing lead times.

- Versatility: Wood laser cutting can be used on a wide variety of wood types, including hardwoods, softwoods, and plywood.

- Durability: Laser-cut wooden items are durable and long-lasting, making them suitable for various applications.

- Aesthetics: Laser cutting enhances the natural beauty of wood, creating unique and visually appealing designs.

Applications of Wooden Laser Cut Items

Wooden laser cut items find applications in a diverse range of industries, including:

- Fiber Laser On Wood Fiber Laser On Wood: A Comprehensive Guide

- Wooden Laser Cut Easter Basket H1: Elevate Your Easter Celebrations With A Wooden Laser Cut Easter Basket: A Timeless Keepsake

- Laser Cut Wooden Bones Laser Cut Wooden Bones: A Detailed Guide To Precision And Customization

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Laser Cut Out Wood Laser Cut Out Wood: A Comprehensive Guide To Precision Cutting And Engraving

- Precision: Laser cutting offers exceptional precision, allowing for the creation of intricate and detailed designs.

- Speed: The laser beam’s high speed enables efficient and rapid production, reducing lead times.

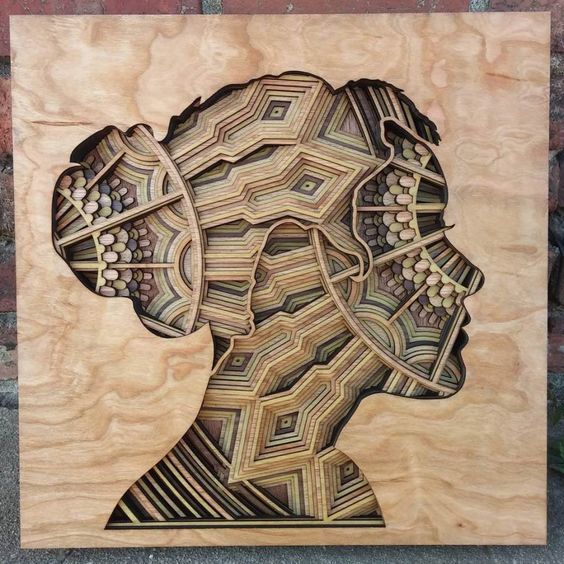

- Home Décor: Laser-cut wooden wall art, furniture, and decorative accents add a touch of elegance and personalization to living spaces.

- Personalized Gifts: Laser-cut wooden items make thoughtful and unique gifts, such as engraved nameplates, photo frames, and personalized keepsakes.

- Industrial Products: Laser-cut wooden components are used in various industries, including automotive, construction, and packaging.

- Signage: Laser-cut wooden signs are durable, weather-resistant, and visually appealing, making them ideal for both indoor and outdoor use.

- Toys and Games: Laser-cut wooden toys and games are safe, educational, and provide hours of entertainment.

- Wood Type: Different wood types have varying properties, such as grain patterns, hardness, and durability. Choosing the appropriate wood type is essential for achieving the desired aesthetics and performance.

- Laser Power: The power of the laser beam determines the depth and precision of the cut. Selecting the appropriate laser power is crucial for ensuring the desired results.

- Design Complexity: Intricate designs require higher laser power and more precise control. The complexity of the design should be considered when choosing the laser cutting equipment.

- Finishing: Laser-cut wooden items can be finished with a variety of techniques, such as staining, painting, or clear coating. The finishing process enhances the aesthetics and protects the wood from moisture and wear.

- Use high-quality wood that is free from knots and imperfections.

- Ensure the wood is properly dried to prevent warping or cracking.

- Adjust the laser power and speed settings to achieve optimal cutting results.

- Use a vector-based design file for precise cutting.

- Clean the laser lens regularly to maintain optimal beam quality.

Understanding Laser Cutting Technology

Laser cutting is a precise manufacturing process that uses a focused laser beam to cut through materials. The laser beam is generated by a laser source and directed onto the material’s surface. The high-intensity beam vaporizes or melts the material, creating a clean and precise cut.

Advantages of Laser Cutting Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Design Considerations for Wooden Laser Cut Items

When designing wooden laser cut items, several factors should be considered:

Tips for Optimizing Wooden Laser Cut Items

Conclusion

Wooden laser cut items offer a wide range of possibilities for creativity, personalization, and practical applications. By understanding laser cutting technology, considering design considerations, and following optimization tips, you can create stunning and functional wooden products that meet your specific needs.

FAQs

Q: What is the best wood type for laser cutting?

A: The best wood type depends on the desired aesthetics and performance. Hardwoods like oak and mahogany offer durability and intricate grain patterns, while softwoods like pine and cedar are more economical and easy to cut.

Q: How can I prevent burning or scorching during laser cutting?

A: Use a low laser power setting, adjust the cutting speed, and ensure the wood is properly dried.

Q: Can I laser cut painted or finished wood?

A: Yes, but it is recommended to test on a small area first as the paint or finish may affect the cutting process.

Q: How can I clean laser-cut wooden items?

A: Use a soft cloth and mild soap solution. Avoid using harsh chemicals or abrasive cleaners.