Laser Cut Wooden Mechanical Models: A Guide to Precision and Creativity

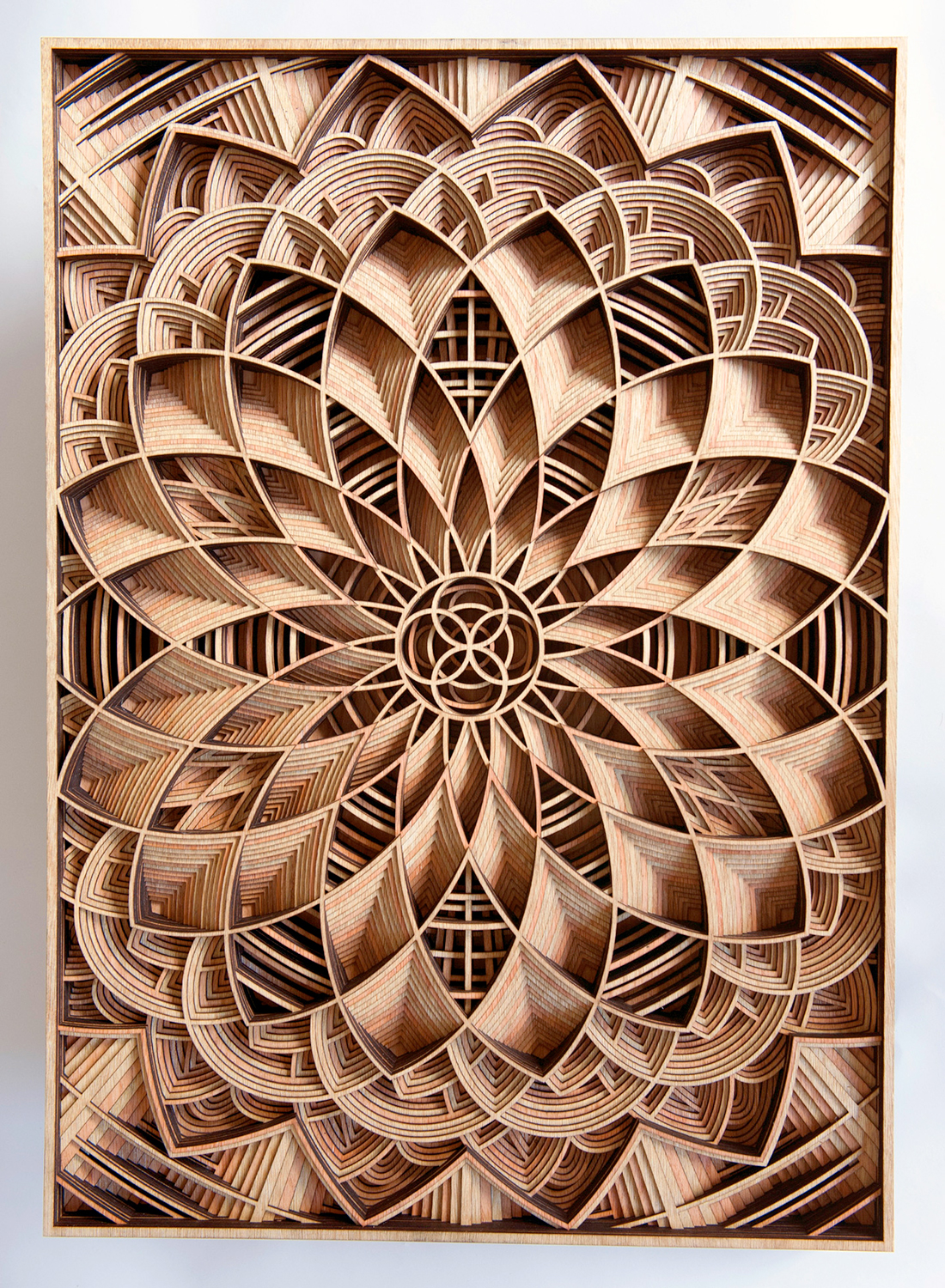

Laser cut wooden mechanical models offer a unique blend of precision engineering and artistic expression. Crafted from high-quality wood and cut with laser precision, these models are not only aesthetically pleasing but also functional, providing a glimpse into the world of mechanics.

H2: The Art of Laser Cutting

Table of Content

- 1 Laser Cut Wooden Mechanical Models: A Guide to Precision and Creativity

- 1.1 H2: The Art of Laser Cutting

- 1.2 H2: Types of Laser Cut Wooden Mechanical Models

- 1.3 H2: The Art of Laser Cutting

- 1.4 H2: Benefits of Laser Cut Wooden Mechanical Models

- 1.5 H2: Building and Assembling Laser Cut Wooden Mechanical Models

- 1.6 H2: Tips for Building Laser Cut Wooden Mechanical Models

- 1.7 H2: Conclusion

- 1.8 H2: FAQs

Laser cutting is a process that uses a focused beam of laser light to cut or engrave materials. In the case of wooden mechanical models, the laser beam is used to cut intricate shapes and patterns into sheets of wood with unmatched accuracy and detail. This technology allows for the creation of complex designs that would be impossible to achieve using traditional woodworking methods.

Laser cut wooden mechanical models offer several advantages over their traditional counterparts:

- Precision: Laser cutting ensures precise cuts and engravings, resulting in models that fit together perfectly and function smoothly.

- Detail: The laser beam can create intricate details, such as gears, pulleys, and other components, with a level of precision that is impossible to achieve by hand.

- Durability: Laser cut wooden models are made from high-quality wood that is durable and long-lasting, making them suitable for both display and play.

- Versatility: Laser cut wooden models can be used for a variety of purposes, including educational toys, decorative objects, and even functional machines.

H2: Types of Laser Cut Wooden Mechanical Models

The range of laser cut wooden mechanical models is vast, encompassing everything from simple puzzles to complex automata. Some popular types include:

- Laser Cut Wooden Figures Laser Cut Wooden Figures: A Comprehensive Guide To Intricate And Personalized Creations

- Laser Wood Cut Out Laser Wood Cut Out: A Comprehensive Guide To Precision Cutting And Artistic Expression

- Custom Laser Cut Wood Signs Custom Laser Cut Wood Signs: Elevate Your Home Decor And Express Yourself

- Laser Cut Wooden Lampshades Laser Cut Wooden Lampshades: Illuminating Your Space With Precision And Style

- Wooden Laser Cutting Near Me Wooden Laser Cutting Near Me: A Comprehensive Guide

- Precision: Laser cutting ensures precise cuts and engravings, resulting in models that fit together perfectly and function smoothly.

- Gears and Pulley Systems: These models demonstrate the principles of mechanical advantage, showing how gears and pulleys can be used to transmit motion and change its speed or direction.

- Clocks: Laser cut wooden clocks are both functional and decorative, featuring intricate designs and precise movements.

- Marquetry: Laser cutting can be used to create intricate marquetry designs, where different pieces of wood are inlaid to form a larger image or pattern.

- Automata: These self-operating models use a combination of gears, cams, and levers to perform a specific action, such as walking, dancing, or playing music.

- Gather Materials: You will need the laser cut wooden parts, glue, sandpaper, and any other necessary tools.

- Prepare the Parts: Remove any protective coverings from the wooden parts and lightly sand them to smooth any rough edges.

- Assemble the Model: Follow the instructions provided with the model to assemble the parts. Use glue to secure the joints and ensure that the model is stable.

- Test the Model: Once the model is assembled, test it to make sure that it functions properly. Adjust any loose or tight joints as needed.

- Finish the Model: You can finish the model by applying a clear or colored finish, such as varnish or paint, to protect the wood and enhance its appearance.

- Read the Instructions Carefully: Before starting to build, carefully read the instructions provided with the model. This will help you understand the assembly process and avoid any mistakes.

- Use the Right Tools: The right tools will make the building process easier and more efficient. Use a sharp knife or craft blade for cutting the parts, and use a small brush for applying glue.

- Be Patient: Building laser cut wooden mechanical models requires patience and precision. Take your time and don’t rush the process.

- Don’t Be Afraid to Experiment: Once you have mastered the basics, don’t be afraid to experiment with different designs and modifications. Laser cutting allows for endless possibilities, so let your creativity flow.

H2: The Art of Laser Cutting

Laser cutting is a process that uses a focused beam of laser light to cut or engrave materials. In the case of wooden mechanical models, the laser beam is used to cut intricate shapes and patterns into sheets of wood with unmatched accuracy and detail. This technology allows for the creation of complex designs that would be impossible to achieve using traditional woodworking methods.

H2: Benefits of Laser Cut Wooden Mechanical Models

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cut wooden mechanical models offer several advantages over their traditional counterparts:

H2: Building and Assembling Laser Cut Wooden Mechanical Models

Building laser cut wooden mechanical models is a rewarding experience that can be enjoyed by people of all ages. The following steps provide a general overview of the process:

H2: Tips for Building Laser Cut Wooden Mechanical Models

H2: Conclusion

Laser cut wooden mechanical models are a testament to the power of precision engineering and the beauty of natural materials. Whether you are looking for an educational toy, a decorative object, or a functional machine, there is a laser cut wooden mechanical model that will meet your needs. With a little patience and attention to detail, you can build and assemble these models to create a unique and rewarding experience.

H2: FAQs

Q: What types of wood are used for laser cut mechanical models?

A: Common types of wood used include birch plywood, mahogany, and maple.

Q: Can laser cut wooden mechanical models be painted or finished?

A: Yes, you can apply a clear or colored finish to protect the wood and enhance its appearance.

Q: Are laser cut wooden mechanical models safe for children?

A: Yes, many laser cut wooden mechanical models are designed to be safe for children to play with. However, always supervise children when they are using sharp tools or handling small parts.

Q: Where can I find laser cut wooden mechanical models?

A: Laser cut wooden mechanical models can be purchased online from various retailers or from local hobby shops.

Q: Can I design and laser cut my own wooden mechanical models?

A: Yes, with the right software and access to a laser cutter, you can design and cut your own wooden mechanical models.