Wood Laser Cutter vs CNC: A Comprehensive Comparison

Introduction

Woodworking enthusiasts and professionals have a wide range of tools at their disposal, including wood laser cutters and CNC machines. Both technologies offer unique advantages and drawbacks, making it essential to understand their differences before making an informed decision. This article provides a comprehensive comparison of wood laser cutters and CNC machines, covering their capabilities, benefits, limitations, and applications.

Table of Content

- 1 Wood Laser Cutter vs CNC: A Comprehensive Comparison

- 1.1 Introduction

- 1.2 H1: Capabilities and Applications

- 1.3 H1: Capabilities and Applications

- 1.4 H2: Benefits of Wood Laser Cutters

- 1.5 H3: Limitations of Wood Laser Cutters

- 1.6 H2: Benefits of CNC Machines

- 1.7 H3: Limitations of CNC Machines

- 1.8 H2: Which Technology is Right for You?

- 1.9 H2: Conclusion

- 1.10 FAQs

H1: Capabilities and Applications

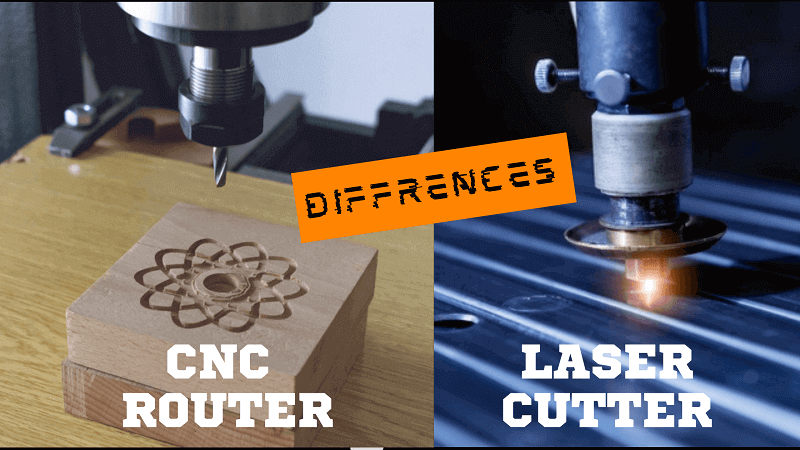

- Precisely cuts, engraves, and marks wood and other materials using a focused laser beam.

- Ideal for intricate designs, detailed engravings, and cutting thin or delicate materials.

- Commonly used for creating art, signage, jewelry, and small wooden objects.

CNC Machine

DOWNLOAD SVG FILES FOR LASER CUTTING

- Uses computer-controlled cutting tools to shape wood and other materials.

- Can perform a wide range of operations, including cutting, routing, carving, and drilling.

- Capable of handling larger pieces and thicker materials compared to laser cutters.

- Laser Cut Wood Design Laser Cut Wood Design: Transforming Woodworking With Precision And Innovation

- Wood Laser Cutouts Wood Laser Cutouts: A Versatile Solution For Diverse Applications

- Small Wooden Laser Cut Tags Small Wooden Laser Cut Tags: A Versatile And Eco-Friendly Solution For Labeling And Customization

- Wood Laser Cutting Wood Laser Cutting: A Comprehensive Guide To Precision And Versatility

- 3d Wooden Puzzle Laser Cut 3D Wooden Puzzle Laser Cut: A Comprehensive Guide

- Precisely cuts, engraves, and marks wood and other materials using a focused laser beam.

- Ideal for intricate designs, detailed engravings, and cutting thin or delicate materials.

- Suitable for producing furniture, cabinetry, and other large-scale woodworking projects.

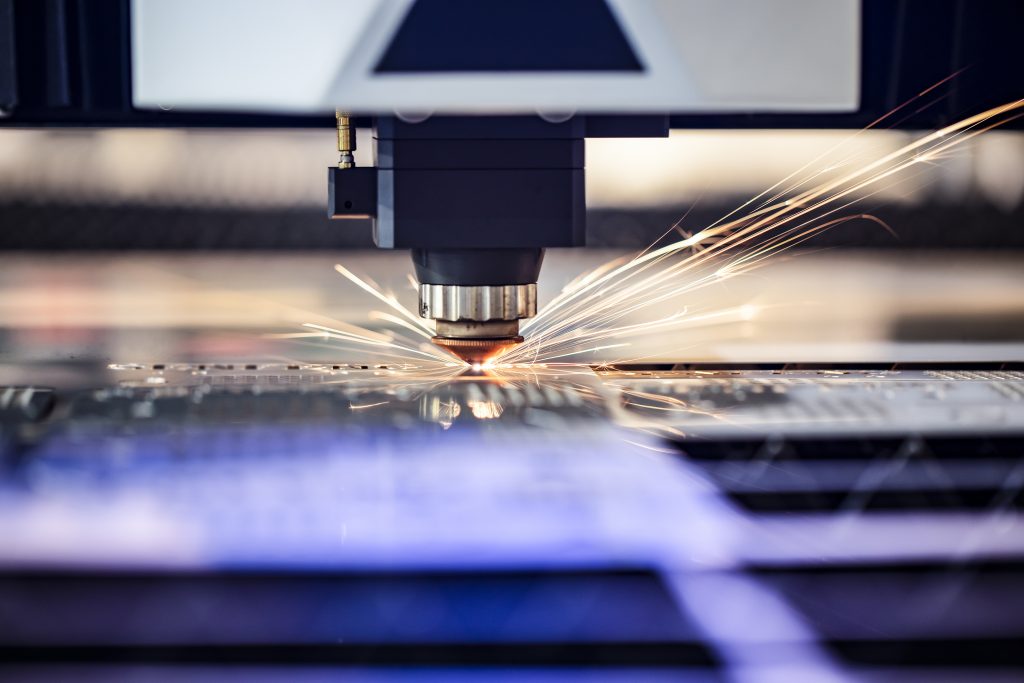

- High Precision: Laser cutters offer exceptional precision, allowing for intricate cuts and detailed engravings.

- Non-Contact Cutting: The laser beam does not physically touch the material, eliminating tool wear and tear.

- Versatility: Can cut a wide range of materials, including wood, acrylic, leather, and fabrics.

- Fast Processing: Laser cutting is a relatively fast process, making it efficient for high-volume production.

- Minimal Waste: Laser cutters produce minimal waste, as they only vaporize the material in the cutting path.

- Limited Cutting Depth: Laser cutters are typically limited to cutting thin materials, with a maximum depth of around 1 inch.

- Material Restrictions: Not all materials are suitable for laser cutting, and some may produce harmful fumes.

- High Initial Cost: Laser cutters can be expensive to purchase and maintain.

- Safety Concerns: Laser beams can be hazardous, requiring proper safety precautions.

- Wide Range of Operations: CNC machines can perform multiple operations, including cutting, routing, carving, and drilling.

- High Power and Torque: CNC routers have powerful motors, enabling them to cut through thicker and harder materials.

- Large Work Area: CNC machines typically have larger work areas than laser cutters, allowing for the production of larger pieces.

- Customizable Tooling: CNC machines can be equipped with a variety of cutting tools, allowing for different cutting styles and finishes.

- Automation: CNC machines can be programmed to automate production processes, saving time and labor costs.

- Less Precision: CNC machines do not offer the same level of precision as laser cutters, especially for intricate designs.

- Tool Wear and Tear: Cutting tools can wear out over time, requiring regular maintenance and replacement.

- Dust and Noise: CNC machines can generate significant dust and noise during operation.

- Limited Versatility: CNC machines are primarily designed for woodworking and may not be suitable for cutting other materials.

- Higher Operating Costs: CNC machines can be expensive to operate, due to the cost of tooling and maintenance.

- Intricate Designs and Small Projects: Wood laser cutters are ideal for projects requiring high precision, intricate details, and cutting thin materials.

- Larger Projects and Thicker Materials: CNC machines are better suited for larger projects, thicker materials, and projects involving multiple operations.

- Budget and Experience: Laser cutters are typically more expensive and require more specialized knowledge to operate than CNC machines.

Woodworking enthusiasts and professionals have a wide range of tools at their disposal, including wood laser cutters and CNC machines. Both technologies offer unique advantages and drawbacks, making it essential to understand their differences before making an informed decision. This article provides a comprehensive comparison of wood laser cutters and CNC machines, covering their capabilities, benefits, limitations, and applications.

H1: Capabilities and Applications

Wood Laser Cutter

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Benefits of Wood Laser Cutters

H3: Limitations of Wood Laser Cutters

H2: Benefits of CNC Machines

H3: Limitations of CNC Machines

H2: Which Technology is Right for You?

The best choice between a wood laser cutter and a CNC machine depends on the specific requirements of the project and the user’s preferences.

H2: Conclusion

Both wood laser cutters and CNC machines are valuable tools for woodworking enthusiasts and professionals. Laser cutters offer exceptional precision and versatility, while CNC machines provide a wide range of operations and the ability to handle larger projects. By understanding the capabilities, benefits, and limitations of each technology, users can make an informed decision based on their specific needs and project requirements.

FAQs

Q: Which technology produces cleaner cuts?

A: Laser cutters produce cleaner cuts with minimal charring or burring.

Q: Can CNC machines cut through metal?

A: Yes, CNC machines with appropriate tooling can cut through metal, but they are not as efficient as dedicated metalworking machines.

Q: Which technology is safer to operate?

A: CNC machines are generally safer to operate than laser cutters, as they do not emit harmful laser beams.

Q: Can laser cutters be used for engraving?

A: Yes, laser cutters can be used for engraving by adjusting the laser power and speed.

Q: Which technology is more expensive to maintain?

A: CNC machines typically require more maintenance than laser cutters, due to the need to replace cutting tools.