Wood Laser Cutter Acrylic: A Comprehensive Guide

Introduction

In the realm of laser cutting, wood and acrylic have emerged as versatile materials, offering distinct advantages for a wide range of applications. A wood laser cutter acrylic machine combines the precision and speed of laser technology with the durability and aesthetics of these materials, unlocking endless possibilities for creators and makers alike. This comprehensive guide will delve into the intricacies of wood laser cutter acrylic, exploring its capabilities, applications, and best practices to empower you with the knowledge to unleash your creativity.

Table of Content

Understanding Wood Laser Cutter Acrylic

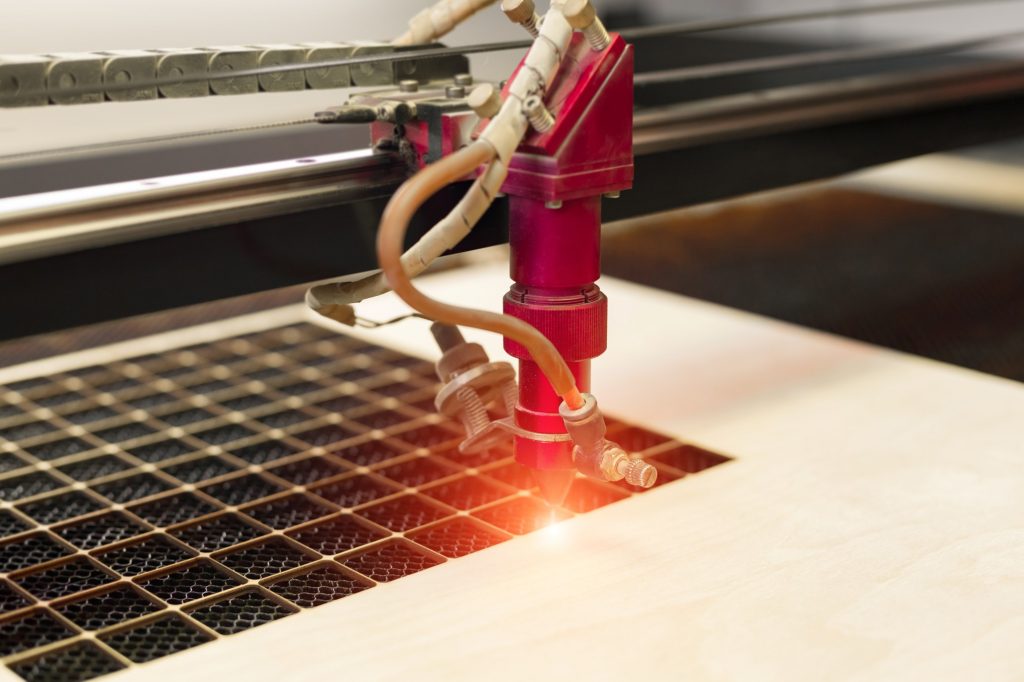

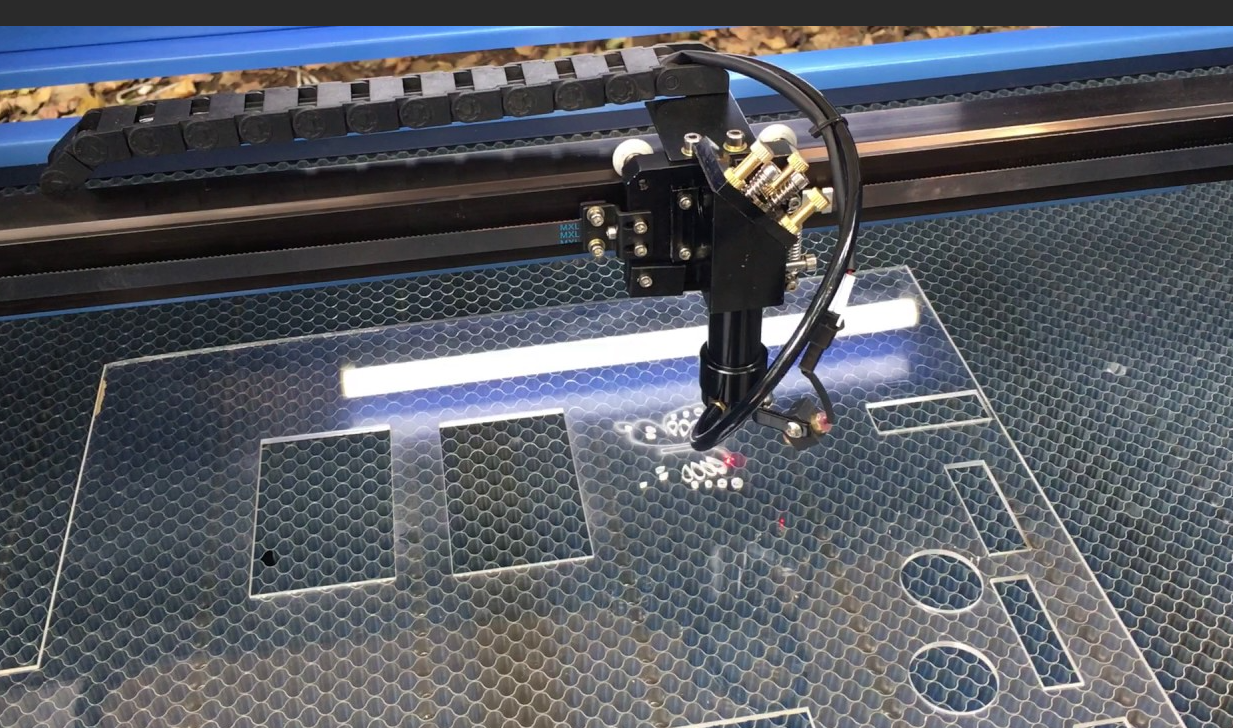

A wood laser cutter acrylic machine utilizes a high-powered laser beam to precisely cut, engrave, or etch intricate designs into wood and acrylic. The laser beam, typically generated by a CO2 or fiber laser, is focused onto the material’s surface, vaporizing or melting it to create the desired shape. This process results in clean, precise cuts with minimal distortion or burring.

H2: Advantages of Using a Wood Laser Cutter Acrylic

- Precision and Accuracy: Laser cutting offers unparalleled precision, enabling intricate designs and precise cuts with minimal variation.

- Speed and Efficiency: Laser cutters operate at high speeds, significantly reducing production time compared to manual or mechanical methods.

- Versatility: Wood laser cutter acrylic machines can handle a wide range of materials, including wood, acrylic, fabric, leather, and more.

- Non-Contact Process: The laser beam does not physically contact the material, eliminating the risk of damage or distortion.

- Minimal Waste: Laser cutting minimizes material waste by utilizing a focused beam, resulting in efficient material usage.

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of Wood Laser Cutter Acrylic

In the realm of laser cutting, wood and acrylic have emerged as versatile materials, offering distinct advantages for a wide range of applications. A wood laser cutter acrylic machine combines the precision and speed of laser technology with the durability and aesthetics of these materials, unlocking endless possibilities for creators and makers alike. This comprehensive guide will delve into the intricacies of wood laser cutter acrylic, exploring its capabilities, applications, and best practices to empower you with the knowledge to unleash your creativity.

- Laser Cut Wood Bookmarks Laser Cut Wood Bookmarks: A Creative And Personal Touch To Your Reading

- Cut Wood Shapes Cut Wood Shapes: A Comprehensive Guide To Precision Cutting Techniques

- Wood Laser Cutter Nz Wood Laser Cutter NZ: A Comprehensive Guide To Precision And Efficiency

- Best Laser Wood Cutter For Small Business Best Laser Wood Cutter For Small Business: A Comprehensive Guide

- Laser Engraver For Wood Laser Engraver For Wood: A Comprehensive Guide

Understanding Wood Laser Cutter Acrylic

H2: How Does a Wood Laser Cutter Acrylic Work?

DOWNLOAD SVG FILES FOR LASER CUTTING

A wood laser cutter acrylic machine utilizes a high-powered laser beam to precisely cut, engrave, or etch intricate designs into wood and acrylic. The laser beam, typically generated by a CO2 or fiber laser, is focused onto the material’s surface, vaporizing or melting it to create the desired shape. This process results in clean, precise cuts with minimal distortion or burring.

H2: Advantages of Using a Wood Laser Cutter Acrylic

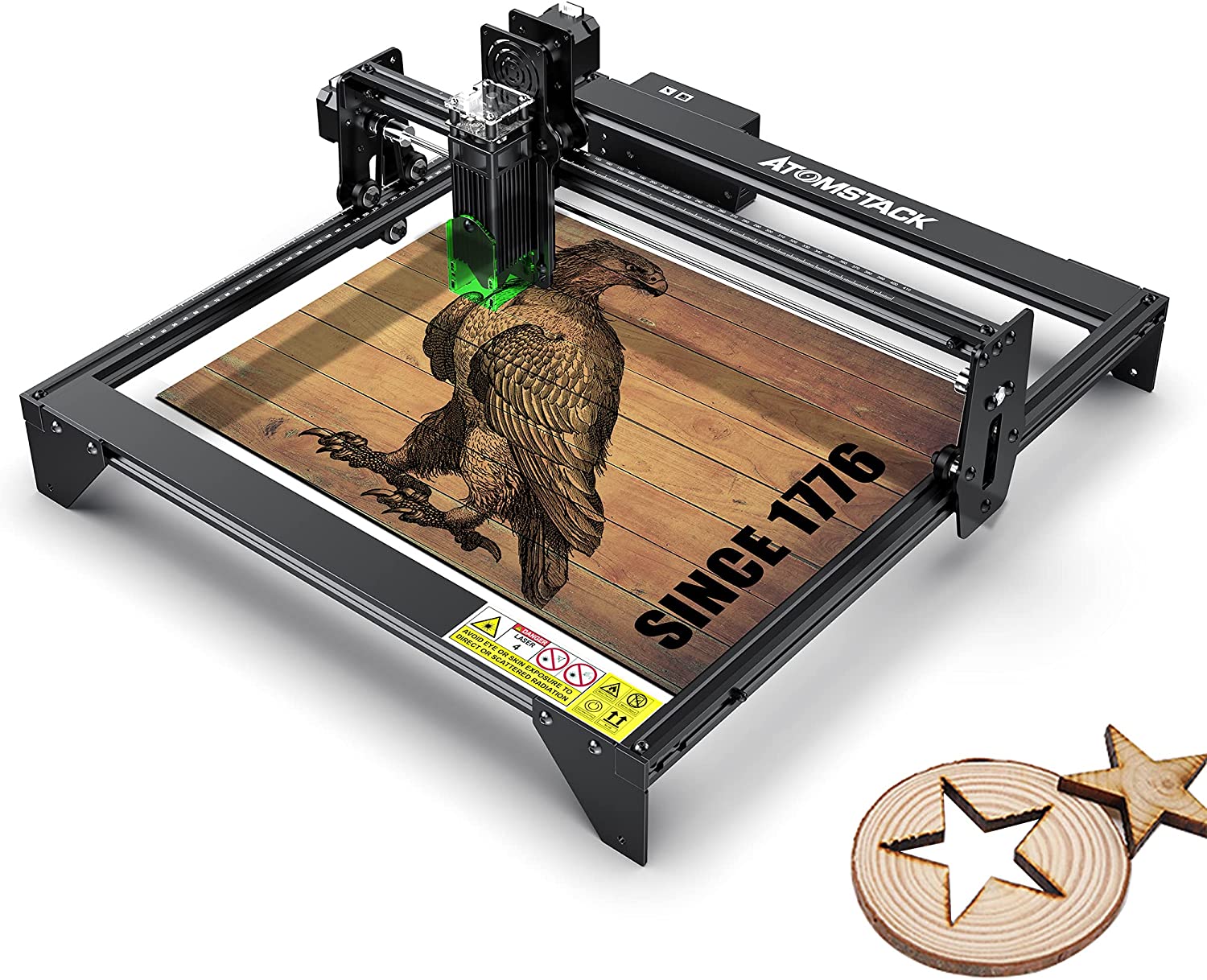

- Personalized Gifts and Decor: Create unique and thoughtful gifts, such as engraved wooden plaques, customized acrylic keychains, and intricate jewelry.

- Home Decor: Design and cut decorative elements for your home, including wall art, coasters, and coasters.

- Model Making: Utilize laser cutting to craft precise and detailed model parts for hobbies or professional projects.

- Signage and Display: Produce high-quality signs, displays, and promotional materials with precise cuts and vibrant colors.

- Product Packaging: Create custom packaging solutions with intricate designs and precise dimensions.

- Medical and Dental Applications: Fabricate precision parts for medical devices, dental implants, and surgical instruments.

- Choose high-quality wood and acrylic materials free from knots, cracks, or imperfections.

- Consider the thickness and density of the material to ensure compatibility with the laser cutter’s capabilities.

- Determine the optimal laser power, speed, and focus settings for the specific material and design requirements.

- Experiment with different settings to achieve the desired cut quality and minimize material damage.

- Wear appropriate safety gear, including eye protection, gloves, and a respirator.

- Ensure the laser cutter is properly ventilated to remove fumes and debris.

- Never leave the laser cutter unattended while in operation.

H2: Wood Laser Cutter Acrylic for Arts and Crafts

H2: Wood Laser Cutter Acrylic for Industrial Applications

Best Practices for Using Wood Laser Cutter Acrylic

H2: Material Selection

H2: Laser Settings

H2: Safety Precautions

Conclusion

Wood laser cutter acrylic machines empower creators and makers with the ability to transform their ideas into tangible masterpieces. By understanding the principles, advantages, and applications of this technology, you can unleash your creativity and produce high-quality products with precision and efficiency. Whether you’re a hobbyist, artist, or industrial manufacturer, a wood laser cutter acrylic machine can elevate your projects to new heights.

FAQs

Q: What is the difference between CO2 and fiber laser cutters?

A: CO2 lasers produce a longer wavelength beam, suitable for cutting and engraving thicker materials. Fiber lasers emit a shorter wavelength beam, offering higher precision and faster cutting speeds.

Q: Can a wood laser cutter acrylic machine cut metal?

A: Most wood laser cutter acrylic machines are not designed to cut metal. However, specialized laser cutters with higher power and different laser sources can be used for metal cutting.

Q: How do I maintain a wood laser cutter acrylic machine?

A: Regular maintenance is crucial to ensure optimal performance. Clean the lens and mirrors regularly, calibrate the laser beam, and inspect the machine for any loose parts or damage.