A Comprehensive Guide to Wood Laser Cutters

Introduction

Laser cutting has revolutionized various industries, including woodworking. Wood laser cutters empower artisans, hobbyists, and businesses to create intricate designs, cut complex shapes, and produce high-quality wooden products with precision and efficiency. This comprehensive article delves into the world of wood laser cutters, exploring their capabilities, applications, and essential considerations for making an informed purchase.

Table of Content

- 1 A Comprehensive Guide to Wood Laser Cutters

- 1.1 Introduction

- 1.2 H1: Understanding Wood Laser Cutters

- 1.2.1 H3: Types of Wood Laser Cutters

- 1.3 H2: Applications of Wood Laser Cutters

- 1.3.2 H3: Hobby and Craft Projects

- 1.4 H1: Understanding Wood Laser Cutters

- 1.4.3 H2: How Do Wood Laser Cutters Work?

- 1.4.4 H3: Types of Wood Laser Cutters

- 1.4.5 H3: Product Manufacturing

- 1.4.6 H3: Prototyping and Design

- 1.5 H1: Choosing the Right Wood Laser Cutter

- 1.5.7 H2: Considerations for Choosing a Wood Laser Cutter

- 1.5.8 H2: Recommended Wood Laser Cutters for Different Applications

- 1.6 H1: Using and Maintaining a Wood Laser Cutter

- 1.6.9 H2: Safety Precautions

- 1.6.10 H2: Maintenance and Calibration

- 1.7 H1: Conclusion

- 1.8 FAQs

H1: Understanding Wood Laser Cutters

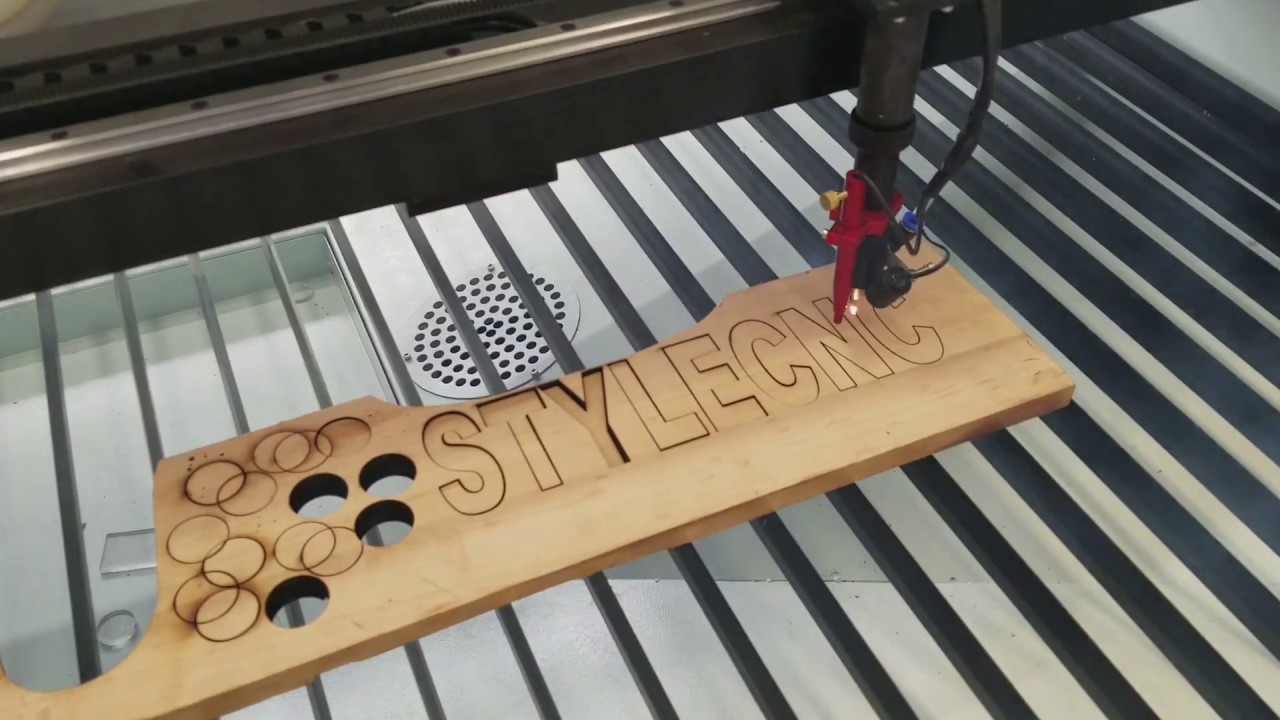

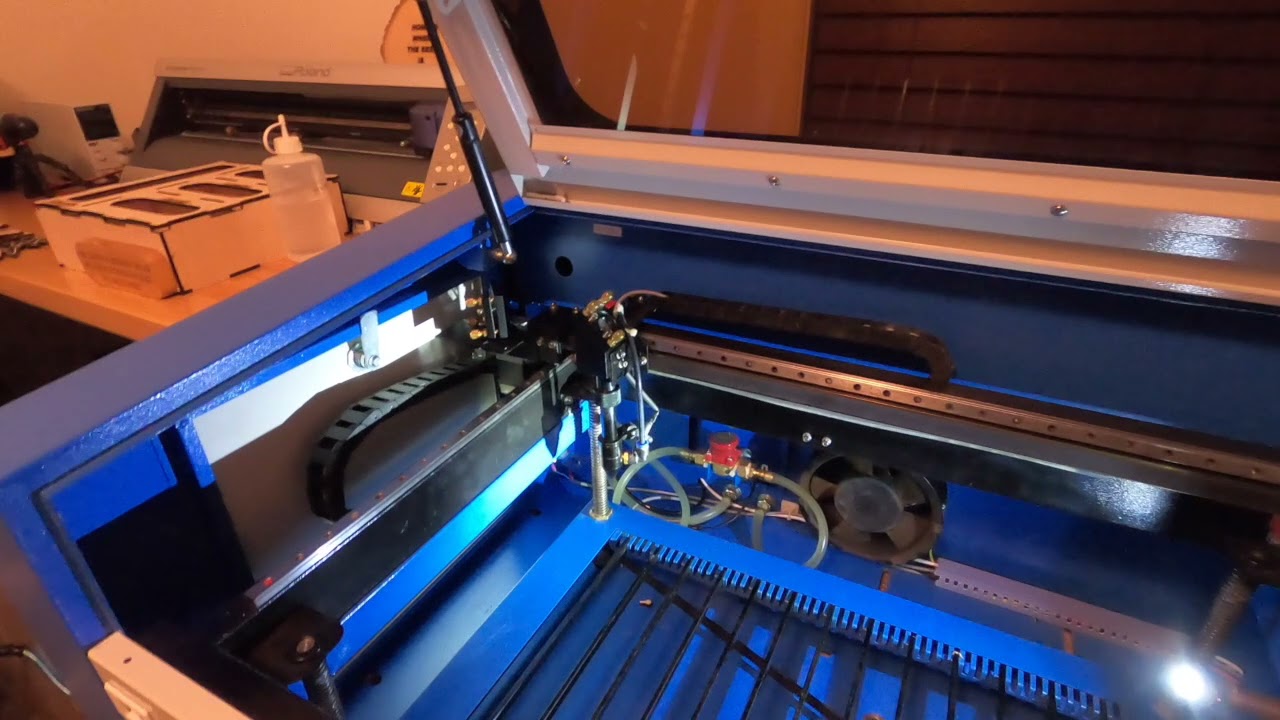

Wood laser cutters utilize a concentrated beam of light, typically a CO2 laser, to vaporize or burn the wood, creating precise cuts and engravings. The laser beam is guided by a computer-controlled system, enabling the creation of intricate designs and complex shapes.

H3: Types of Wood Laser Cutters

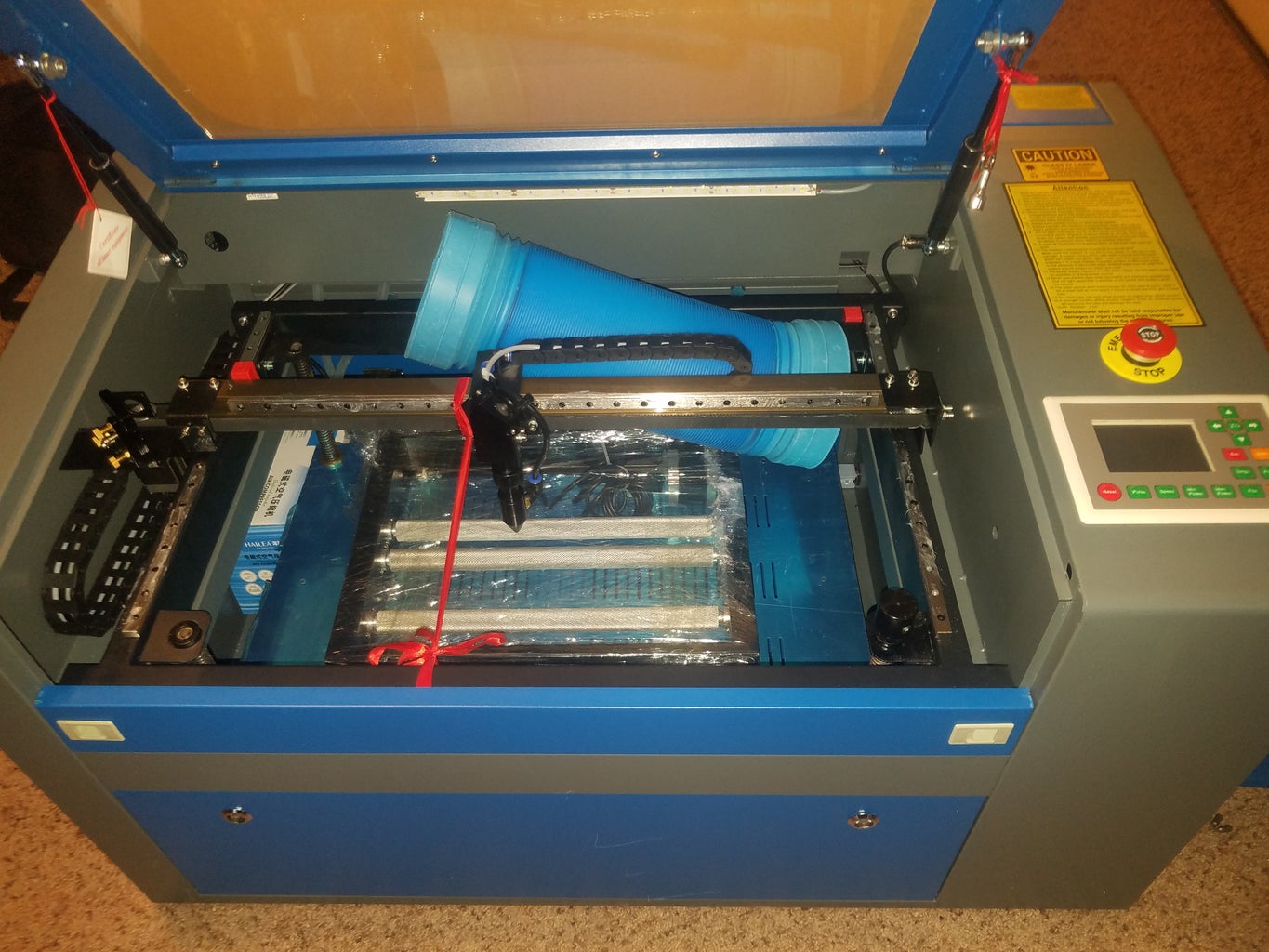

- CO2 Laser Cutters: The most common type, using carbon dioxide gas to generate the laser beam.

- Fiber Laser Cutters: Use optical fibers to generate the laser beam, resulting in higher cutting speeds and lower operating costs.

- Diode Laser Cutters: Compact and affordable, suitable for smaller-scale applications.

H2: Applications of Wood Laser Cutters

H3: Hobby and Craft Projects

- Laser Cut Wooden Box Template Free H1: Laser Cut Wooden Box Template Free: Elevate Your Crafting Skills

- Handheld Laser Wood Cutter Handheld Laser Wood Cutter: A Comprehensive Guide

- Laser Wood Company Laser Wood Company: Revolutionizing Woodworking With Precision And Innovation

- Wooden Laser Cut Products Wooden Laser Cut Products: A Comprehensive Guide To Customization And Versatility

- Laser Cut Wooden Medals Laser Cut Wooden Medals: A Unique And Sustainable Way To Recognize Achievement

- Creating custom home décor items

- Intricate wood jewelry and accessories

- Personalized gifts and keepsakes

- Cutting wooden components for furniture, toys, and musical instruments

- Engraving logos and designs on wooden products

- Producing custom signage and displays

- Rapid prototyping for product development

- Creating scale models for architectural or engineering projects

- Developing custom fixtures and jigs

- Cutting Power: Measured in watts, determines the thickness of wood that can be cut.

- Cutting Area: The size of the work area determines the maximum size of projects that can be cut.

- Resolution: Measured in dots per inch (DPI), affects the precision and detail of cuts and engravings.

- Software Compatibility: Ensure the laser cutter is compatible with your design software.

- Budget: Laser cutters vary significantly in price depending on capabilities and features.

- Hobbyists: Diode or small CO2 laser cutters with a cutting area of 12" x 12" or less.

- Small Businesses: Mid-range CO2 laser cutters with a cutting area of 24" x 18" or larger.

- Industrial Applications: High-power fiber laser cutters with large cutting areas and advanced automation features.

- Wear appropriate safety gear (glasses, gloves, dust mask).

- Ensure proper ventilation to remove fumes and smoke.

- Never leave the laser cutter unattended while in operation.

- Regularly clean the laser lens and mirrors.

- Calibrate the laser cutter periodically to maintain accuracy.

- Check the alignment of the cutting head and work surface.

- Q: What types of wood can be cut with a laser cutter?

- A: Most types of wood can be cut, including hardwoods, softwoods, and plywood.

- Q: How thick of wood can a laser cutter cut?

- A: The cutting thickness depends on the power of the laser cutter. Typically, CO2 laser cutters can cut wood up to 1" thick, while fiber laser cutters can cut thicker materials.

- Q: Can laser cutters engrave wood?

- A: Yes, laser cutters can engrave intricate designs and text on wood surfaces.

- Q: What is the cost of operating a laser cutter?

- A: Operating costs vary depending on the size, power, and usage of the laser cutter. Factors include electricity consumption, laser gas replacement, and maintenance.

Laser cutting has revolutionized various industries, including woodworking. Wood laser cutters empower artisans, hobbyists, and businesses to create intricate designs, cut complex shapes, and produce high-quality wooden products with precision and efficiency. This comprehensive article delves into the world of wood laser cutters, exploring their capabilities, applications, and essential considerations for making an informed purchase.

H1: Understanding Wood Laser Cutters

H2: How Do Wood Laser Cutters Work?

DOWNLOAD SVG FILES FOR LASER CUTTING

Wood laser cutters utilize a concentrated beam of light, typically a CO2 laser, to vaporize or burn the wood, creating precise cuts and engravings. The laser beam is guided by a computer-controlled system, enabling the creation of intricate designs and complex shapes.

H3: Types of Wood Laser Cutters

H3: Product Manufacturing

H3: Prototyping and Design

H1: Choosing the Right Wood Laser Cutter

H2: Considerations for Choosing a Wood Laser Cutter

H2: Recommended Wood Laser Cutters for Different Applications

H1: Using and Maintaining a Wood Laser Cutter

H2: Safety Precautions

H2: Maintenance and Calibration

H1: Conclusion

Wood laser cutters are versatile and powerful tools that enable precise cutting, engraving, and prototyping in the woodworking industry. By understanding the different types, applications, and considerations involved in choosing a wood laser cutter, users can make informed decisions that meet their specific needs. With proper safety precautions and maintenance, wood laser cutters can enhance creativity, efficiency, and product quality in various applications.

FAQs