Building a Wood Laser Cutter: A Comprehensive Guide

Introduction

Laser cutters have revolutionized the way we create and manufacture products from various materials, including wood. Building your own wood laser cutter offers numerous advantages, such as customization, cost-effectiveness, and the ability to tailor it to your specific needs. This article provides a detailed guide to building a wood laser cutter, covering every aspect from selecting components to assembling and calibrating the machine.

Table of Content

- 1 Building a Wood Laser Cutter: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Component Selection

- 1.2.1 H2: Controller and Software

- 1.2.2 H2: Laser Optics

- 1.2.3 H2: Motion System

- 1.2.4 H2: Workspace

- 1.3 H2: Assembly and Calibration

- 1.4 H1: Component Selection

- 1.4.5 H2: Laser Source

- 1.4.6 H2: Controller and Software

- 1.4.7 H3: Mechanical Assembly

- 1.4.8 H3: Electrical Wiring

- 1.4.9 H3: Software Configuration

- 1.4.10 H3: Calibration

- 1.5 H1: Operation and Maintenance

- 1.5.11 H2: Safety Precautions

- 1.5.12 H2: Cutting Parameters

- 1.5.13 H2: Material Handling

- 1.5.14 H2: Maintenance

- 1.6 Conclusion

- 1.7 FAQs

- 1.7.15 Q: What is the cost of building a wood laser cutter?

- 1.7.16 Q: Can I cut other materials besides wood?

- 1.7.17 Q: How long does it take to build a wood laser cutter?

- 1.7.18 Q: Is it difficult to operate a wood laser cutter?

H1: Component Selection

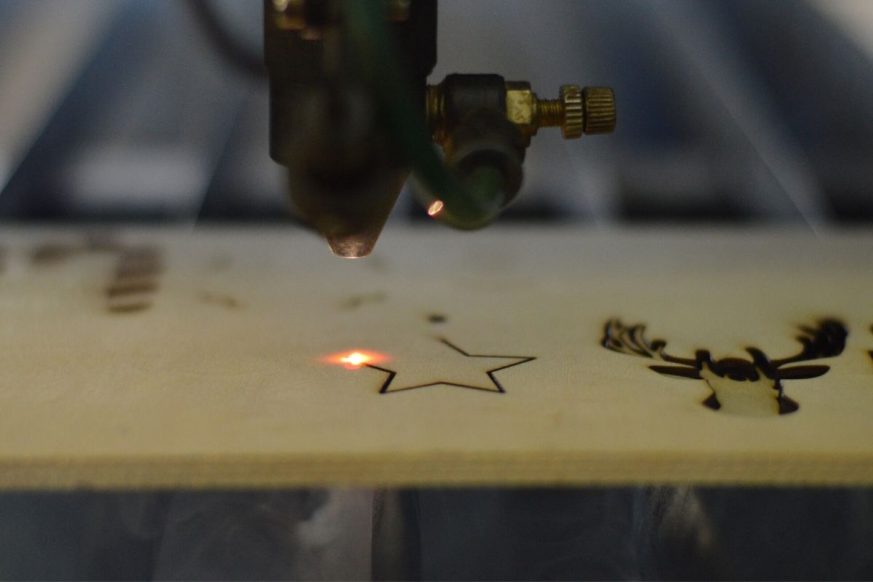

The laser source is the heart of any laser cutter. For wood cutting, CO2 lasers are the most suitable due to their high power and affordability. Consider factors such as laser power (typically 40-80W for wood cutting), wavelength (10.6µm for CO2 lasers), and beam quality.

H2: Controller and Software

The controller is responsible for controlling the laser source and other components. Choose a controller compatible with your laser source and operating system. The software allows you to design and send cutting paths to the controller.

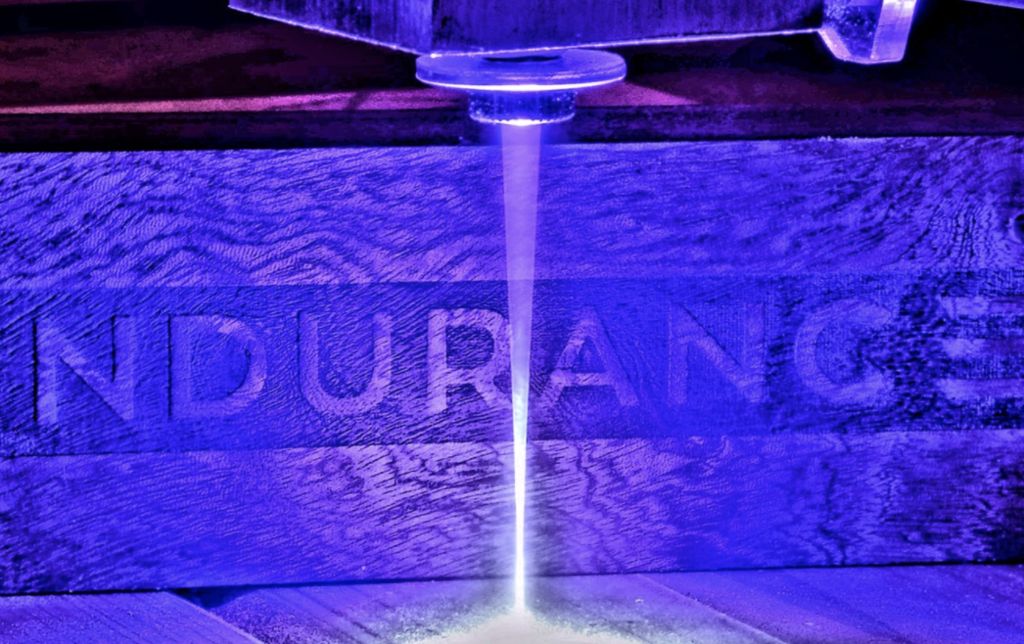

H2: Laser Optics

Laser optics include mirrors and lenses that direct and focus the laser beam. High-quality optics ensure precise cutting and minimize beam distortion. Select mirrors with high reflectivity and lenses with appropriate focal lengths.

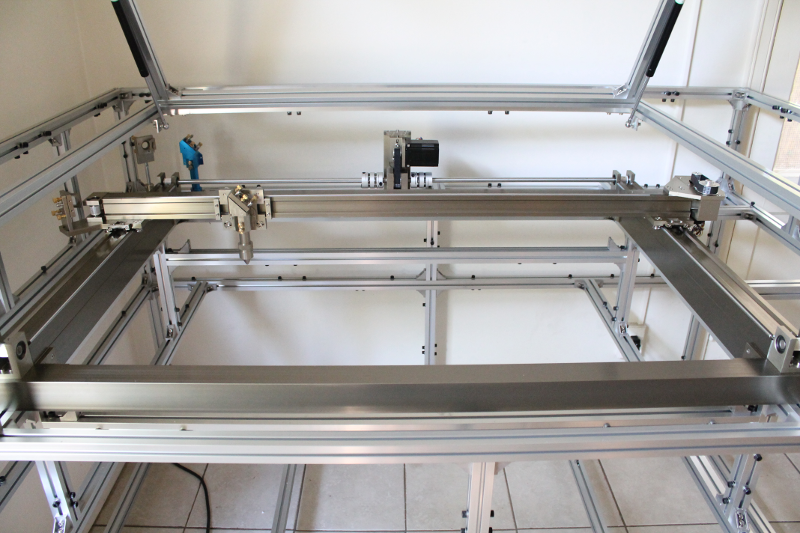

H2: Motion System

DOWNLOAD SVG FILES FOR LASER CUTTING

The motion system moves the laser head over the workpiece. Consider factors such as accuracy, speed, and reliability. Stepper motors or servo motors can be used for motion control.

H2: Workspace

Determine the maximum cutting area and depth required for your projects. The workspace size should be sufficient to accommodate the largest pieces you intend to cut.

H2: Assembly and Calibration

Laser cutters have revolutionized the way we create and manufacture products from various materials, including wood. Building your own wood laser cutter offers numerous advantages, such as customization, cost-effectiveness, and the ability to tailor it to your specific needs. This article provides a detailed guide to building a wood laser cutter, covering every aspect from selecting components to assembling and calibrating the machine.

- Custom Laser Cut Wood Panels Custom Laser Cut Wood Panels: Elevate Your Designs With Precision And Versatility

- Etsy Wooden Laser Cut Flowers Etsy Wooden Laser Cut Flowers: A Guide To Customization And Elegance

- Wooden Laser Cut Words H1: Wooden Laser Cut Words: A Versatile And Eye-Catching Embellishment

- Laser Cut Wood Items Laser Cut Wood Items: A Comprehensive Guide To Crafting Unique And Precise Creations

- Co2 Laser Wood Engraving CO2 Laser Wood Engraving: A Comprehensive Guide To Precision And Creativity

H1: Component Selection

H2: Laser Source

DOWNLOAD SVG FILES FOR LASER CUTTING

The laser source is the heart of any laser cutter. For wood cutting, CO2 lasers are the most suitable due to their high power and affordability. Consider factors such as laser power (typically 40-80W for wood cutting), wavelength (10.6µm for CO2 lasers), and beam quality.

H2: Controller and Software

The controller is responsible for controlling the laser source and other components. Choose a controller compatible with your laser source and operating system. The software allows you to design and send cutting paths to the controller.

H3: Mechanical Assembly

Assemble the mechanical components, including the laser head, motion system, and workspace. Ensure proper alignment and rigidity.

H3: Electrical Wiring

Connect the laser source, controller, and other components according to the manufacturer’s instructions. Use proper grounding and safety measures.

H3: Software Configuration

Install the software and configure the controller settings, including laser power, cutting speed, and motion parameters.

H3: Calibration

Calibrate the laser optics to ensure optimal beam quality and focus. Adjust the motion system for accuracy and repeatability.

H1: Operation and Maintenance

H2: Safety Precautions

Laser cutters emit high-power laser radiation. Always wear proper safety gear, including laser safety glasses, and follow safety protocols.

H2: Cutting Parameters

Optimize cutting parameters such as laser power, speed, and focus based on the type of wood and desired results. Experimentation is crucial to find the optimal settings.

H2: Material Handling

Secure the workpiece properly to prevent movement during cutting. Use appropriate hold-downs or vacuum systems.

H2: Maintenance

Regular maintenance is essential to ensure optimal performance and longevity. Clean optics regularly, lubricate moving parts, and monitor laser source health.

Conclusion

Building a wood laser cutter is a rewarding project that empowers you to create precise and intricate designs from wood. By carefully selecting components, assembling them correctly, and calibrating the machine, you can achieve professional-grade results. Embrace the learning process, experiment with different parameters, and unlock the full potential of your custom-built wood laser cutter.

FAQs

Q: What is the cost of building a wood laser cutter?

A: The cost varies depending on the components used. Expect to spend around $1,500-$3,000 for a basic machine.

Q: Can I cut other materials besides wood?

A: Yes, but it depends on the laser source and wavelength. Some lasers can cut acrylic, leather, and other non-metallic materials.

Q: How long does it take to build a wood laser cutter?

A: Allow for several days to a week for assembly and calibration, depending on your experience level.

Q: Is it difficult to operate a wood laser cutter?

A: With proper training and safety precautions, operating a wood laser cutter is relatively straightforward. However, it requires some technical knowledge and practice.