How Does a Wood Laser Cutter Work?

Introduction

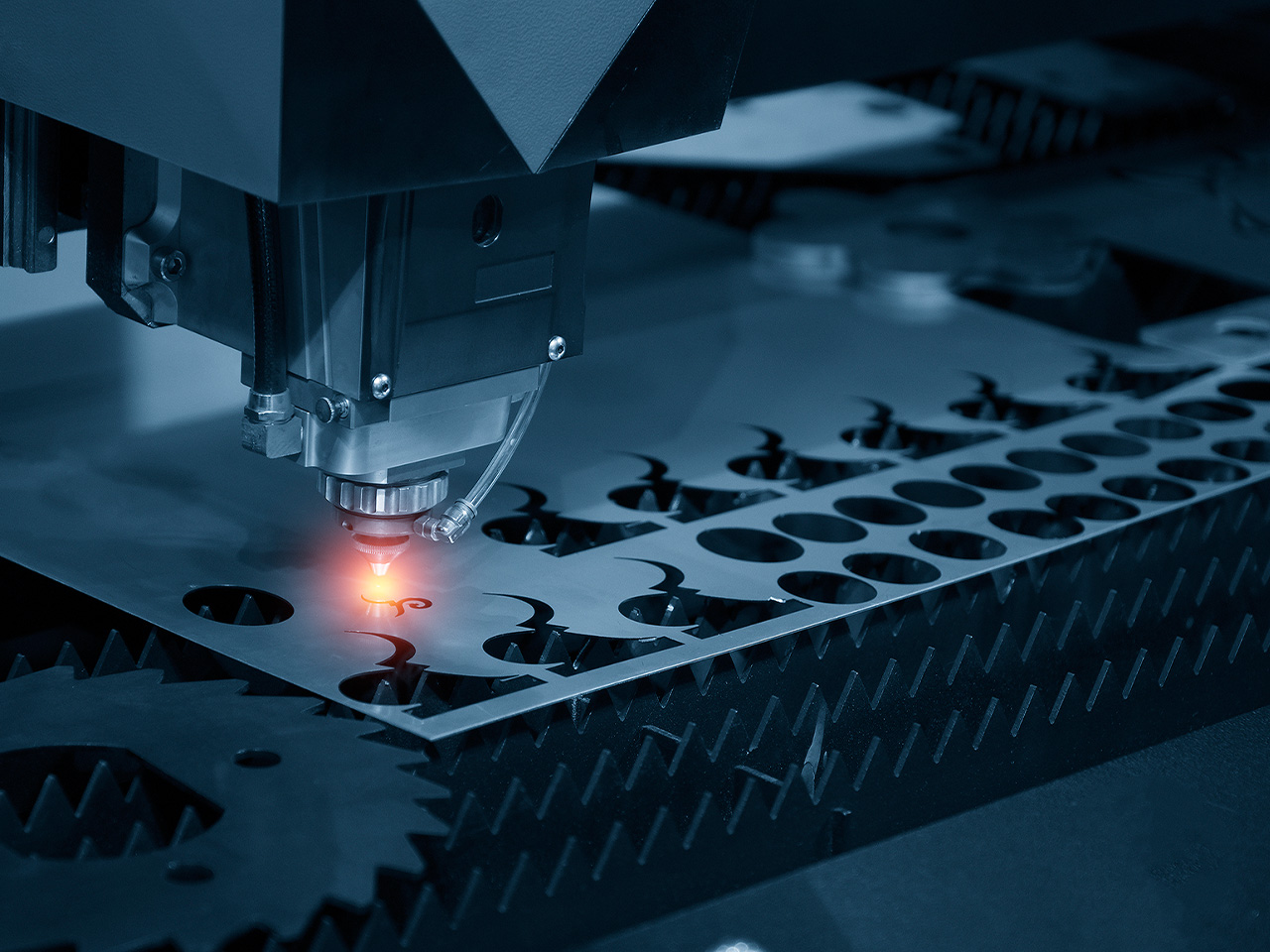

Laser cutters are becoming increasingly popular for cutting and engraving wood due to their precision, speed, and versatility. Understanding how these machines operate is essential for maximizing their capabilities and achieving optimal results. This comprehensive guide will delve into the intricate workings of a wood laser cutter, exploring its components, processes, and applications.

Table of Content

- 1 How Does a Wood Laser Cutter Work?

- 2 Components of a Wood Laser Cutter

- 2.1 2. Laser Optics

- 3 Components of a Wood Laser Cutter

- 3.2 1. Laser Source

- 3.3 3. Cutting Table

- 3.4 4. Motion Control System

- 3.5 5. Exhaust System

- 4 Processes of a Wood Laser Cutter

- 4.6 1. Laser Cutting

- 4.7 2. Laser Engraving

- 4.8 3. Laser Marking

- 5 Applications of Wood Laser Cutters

- 6 Conclusion

Components of a Wood Laser Cutter

The laser source is the heart of the laser cutter. It generates a high-powered laser beam that is directed towards the cutting surface. The most common types of laser sources used in wood laser cutters are:

- CO2 Laser: Emits infrared light with a wavelength of 10.6 μm, ideal for cutting and engraving wood.

- Fiber Laser: Emits visible light with a wavelength of 1.06 μm, offering higher efficiency and faster cutting speeds.

2. Laser Optics

DOWNLOAD SVG FILES FOR LASER CUTTING

The laser optics consist of a series of mirrors and lenses that guide and focus the laser beam onto the cutting surface. These components include:

- Beam Expander: Enlarges the laser beam to increase its power density.

- Laser Head: Directs the laser beam onto the material being cut.

- Laser Cut Wood Panels Laser Cut Wood Panels: A Comprehensive Guide

- Cricut Wood Etching Cricut Wood Etching: A Comprehensive Guide For Beginners And Experts

- Laser Cut Wooden Signs Australia Laser Cut Wooden Signs Australia: The Ultimate Guide To Custom Engraved Decor

- Laser Cut Wooden Dream Catcher Laser Cut Wooden Dream Catcher: A Guide To Creating A Unique And Meaningful Home Decor

- Laser Cut Wood Suppliers Laser Cut Wood Suppliers: A Comprehensive Guide

- CO2 Laser: Emits infrared light with a wavelength of 10.6 μm, ideal for cutting and engraving wood.

- Focusing Lens: Focuses the laser beam to a precise point on the cutting surface.

- Stepper Motors: Drive the laser head along the X and Y axes.

- Linear Guides: Provide smooth and accurate movement.

- Laser Power: Higher power results in faster cutting speeds and thicker material cuts.

- Cutting Speed: Determines the speed at which the laser head moves along the cutting path.

- Focus: Proper focusing ensures the laser beam is concentrated on the cutting surface.

- Laser Power: Lower power settings are used for fine engraving, while higher power is suitable for deeper engraving.

- Engraving Speed: Slower speeds produce higher-quality engravings with more detail.

- Furniture Manufacturing: Cutting and engraving intricate designs on furniture components.

- Musical Instrument Making: Creating soundboards, guitar bodies, and other musical instrument parts.

- Art and Crafts: Engraving and cutting decorative items, signs, and jewelry.

- Prototyping and Model Making: Creating prototypes and models for product development.

Laser cutters are becoming increasingly popular for cutting and engraving wood due to their precision, speed, and versatility. Understanding how these machines operate is essential for maximizing their capabilities and achieving optimal results. This comprehensive guide will delve into the intricate workings of a wood laser cutter, exploring its components, processes, and applications.

Components of a Wood Laser Cutter

1. Laser Source

DOWNLOAD SVG FILES FOR LASER CUTTING

The laser source is the heart of the laser cutter. It generates a high-powered laser beam that is directed towards the cutting surface. The most common types of laser sources used in wood laser cutters are:

3. Cutting Table

The cutting table provides a stable and level surface for the material being cut. It typically has a honeycomb structure to allow for smoke and debris to escape.

4. Motion Control System

The motion control system guides the laser head along the cutting path. It consists of:

5. Exhaust System

The exhaust system removes smoke, fumes, and debris from the cutting area. It consists of:

Processes of a Wood Laser Cutter

1. Laser Cutting

Laser cutting is the primary process used to cut wood. The high-powered laser beam melts or vaporizes the material, creating a precise cut. The following factors influence the laser cutting process:

2. Laser Engraving

Laser engraving is used to create intricate designs and patterns on wood surfaces. The laser beam is directed onto the surface, removing a thin layer of material to create a recessed image. The following factors affect laser engraving:

3. Laser Marking

Laser marking is a non-contact process that creates permanent marks on wood surfaces. The laser beam darkens or changes the color of the wood without removing any material.

Applications of Wood Laser Cutters

Laser cutters are versatile machines with a wide range of applications in the woodworking industry, including:

Conclusion

Wood laser cutters are powerful and versatile machines that offer precision, speed, and versatility in woodworking applications. Understanding the components, processes, and applications of these machines is crucial for maximizing their capabilities and achieving optimal results. By carefully considering factors such as laser power, cutting speed, and focus, users can achieve precise cuts, intricate engravings, and permanent marks on wood surfaces.