Wood Laser Cutter CNC: The Ultimate Guide to Precision Woodworking

Introduction

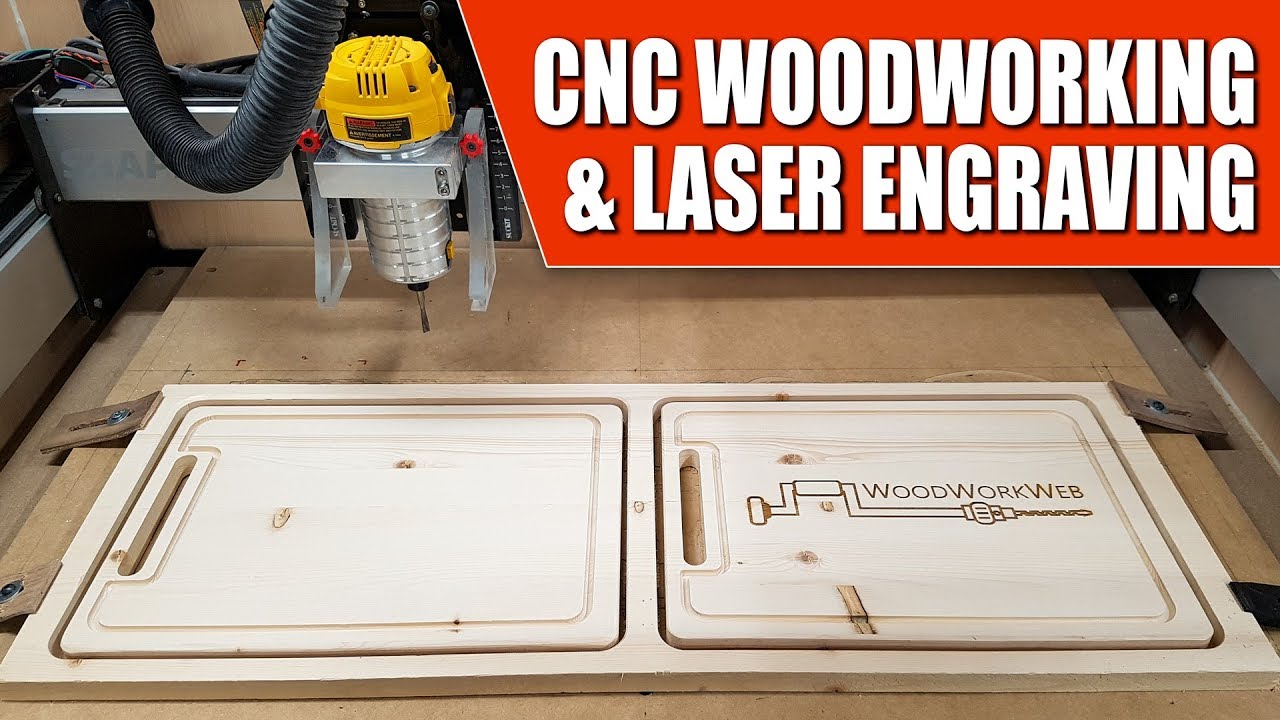

Wood laser cutters CNC (Computer Numerical Control) are revolutionary tools that have transformed the woodworking industry. These machines utilize advanced laser technology to precisely cut, engrave, and etch wood, enabling intricate designs and complex projects with unparalleled accuracy. This article delves into the world of wood laser cutter CNCs, exploring their capabilities, benefits, and applications.

Table of Content

- 1 Wood Laser Cutter CNC: The Ultimate Guide to Precision Woodworking

- 1.1 Introduction

- 1.2 How Do Wood Laser Cutter CNCs Work?

- 1.3 Types of Wood Laser Cutter CNCs

- 1.4 Benefits of Using Wood Laser Cutter CNCs

- 1.5 How Do Wood Laser Cutter CNCs Work?

- 1.6 Types of Wood Laser Cutter CNCs

- 1.7 Applications of Wood Laser Cutter CNCs

- 1.8 Choosing the Right Wood Laser Cutter CNC

- 1.9 Conclusion

- 1.10 FAQs

How Do Wood Laser Cutter CNCs Work?

Types of Wood Laser Cutter CNCs

There are two main types of wood laser cutter CNCs:

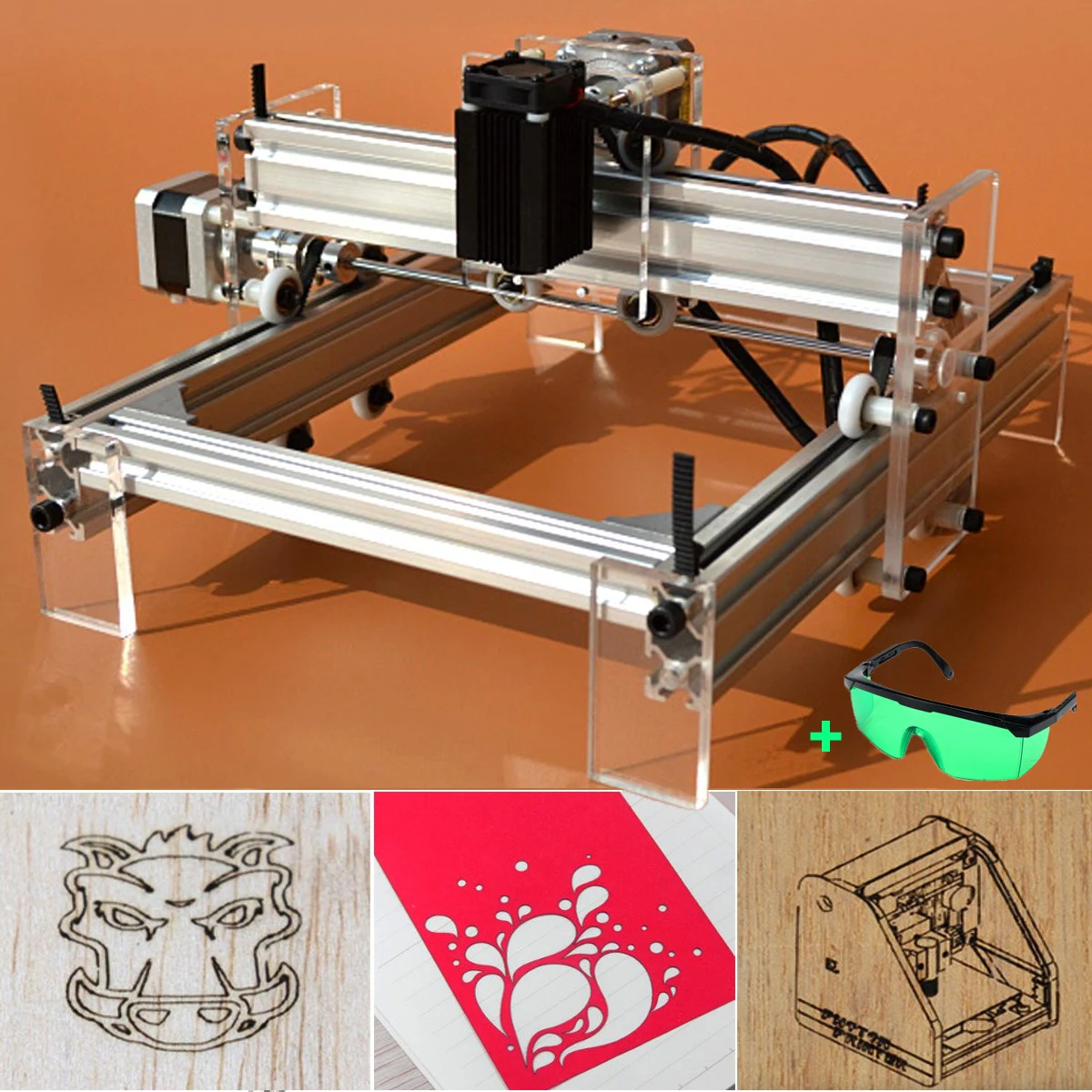

- CO2 Laser Cutter CNCs: These machines use carbon dioxide (CO2) gas to generate the laser beam. They are known for their high power and speed, making them suitable for cutting and engraving thicker wood materials.

- Fiber Laser Cutter CNCs: These machines utilize fiber optics to generate the laser beam. They offer higher precision and finer detail than CO2 laser cutters, making them ideal for intricate engraving and cutting thin materials.

DOWNLOAD SVG FILES FOR LASER CUTTING

Benefits of Using Wood Laser Cutter CNCs

- Precision and Accuracy: Laser cutters CNCs deliver exceptional precision and accuracy, ensuring consistent results even for complex designs.

- Speed and Efficiency: These machines can process wood rapidly, significantly increasing production speed and efficiency.

- Laser Cut Wood Shapes Laser Cut Wood Shapes: Unleashing Creativity And Precision

- Laser Cut Wooden Advent Calendar Laser Cut Wooden Advent Calendar: A Festive Countdown To Christmas

- Wooden Laser Cut Wooden Laser Cut: Precision Cutting For Intricate Designs

- Small Wooden Laser Cut Tags Small Wooden Laser Cut Tags: A Versatile And Eco-Friendly Solution For Labeling And Customization

- Personalised Laser Cut Wooden Heart Personalised Laser Cut Wooden Heart: A Timeless Expression Of Love And Connection

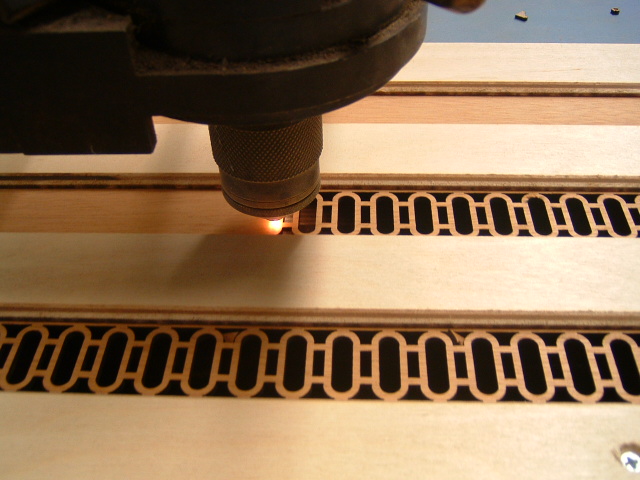

- Versatility: Wood laser cutter CNCs can perform a wide range of tasks, including cutting, engraving, etching, and marking.

- Automation: CNC systems automate the cutting process, reducing the need for manual labor and minimizing human error.

- Intricate Designs: Laser cutters CNCs can create intricate designs and patterns with ease, opening up new possibilities for woodworking projects.

- Furniture Manufacturing: Cutting and engraving intricate patterns on furniture pieces, such as headboards, tabletops, and chairs.

- Musical Instrument Making: Creating guitar bodies, violin scrolls, and other musical instrument components with precision.

- Art and Decor: Producing custom artwork, signs, and home decor items with unique designs.

- Industrial Applications: Laser cutting wood for packaging, prototyping, and other industrial purposes.

- Power: Determine the laser power required based on the thickness and type of wood you plan to process.

- Speed: Consider the desired cutting and engraving speed to ensure efficient production.

- Accuracy: Ensure the machine provides the precision and accuracy needed for your projects.

- Software Compatibility: Check the compatibility of the machine’s software with your design programs.

- Safety Features: Prioritize machines with safety features such as laser beam enclosures and fume extraction systems.

Wood laser cutters CNC (Computer Numerical Control) are revolutionary tools that have transformed the woodworking industry. These machines utilize advanced laser technology to precisely cut, engrave, and etch wood, enabling intricate designs and complex projects with unparalleled accuracy. This article delves into the world of wood laser cutter CNCs, exploring their capabilities, benefits, and applications.

How Do Wood Laser Cutter CNCs Work?

Wood laser cutter CNCs operate on the principle of laser ablation. A high-powered laser beam is focused onto the wood surface, vaporizing or burning away material to create precise cuts or engravings. The CNC system guides the laser head, following a pre-programmed design, ensuring accuracy and repeatability.

DOWNLOAD SVG FILES FOR LASER CUTTING

Types of Wood Laser Cutter CNCs

There are two main types of wood laser cutter CNCs:

Applications of Wood Laser Cutter CNCs

Wood laser cutter CNCs are used in various industries, including:

Choosing the Right Wood Laser Cutter CNC

When selecting a wood laser cutter CNC, consider the following factors:

Conclusion

Wood laser cutter CNCs have revolutionized woodworking, enabling unparalleled precision, speed, and versatility. They offer a wide range of applications, from furniture manufacturing to art and decor. By carefully considering the factors discussed in this article, you can select the right wood laser cutter CNC to meet your specific needs and elevate your woodworking capabilities.

FAQs

1. What materials can wood laser cutter CNCs process?

Wood laser cutter CNCs can process various types of wood, including plywood, MDF, hardwood, and softwood.

2. Are wood laser cutter CNCs safe to use?

Yes, wood laser cutter CNCs are safe to use when operated correctly. They typically feature safety features such as laser beam enclosures and fume extraction systems.

3. What maintenance is required for wood laser cutter CNCs?

Regular maintenance is essential to ensure optimal performance and longevity. This includes cleaning the laser lens, adjusting mirrors, and lubricating moving parts.

4. How can I design projects for wood laser cutter CNCs?

Design software such as CorelDRAW, AutoCAD, and Inkscape can be used to create designs for wood laser cutter CNCs.

5. What is the cost of a wood laser cutter CNC?

The cost of a wood laser cutter CNC varies depending on the size, power, and features. Prices can range from a few thousand dollars to hundreds of thousands of dollars.