Laser Cutter for Wood Cutouts: A Comprehensive Guide

Introduction

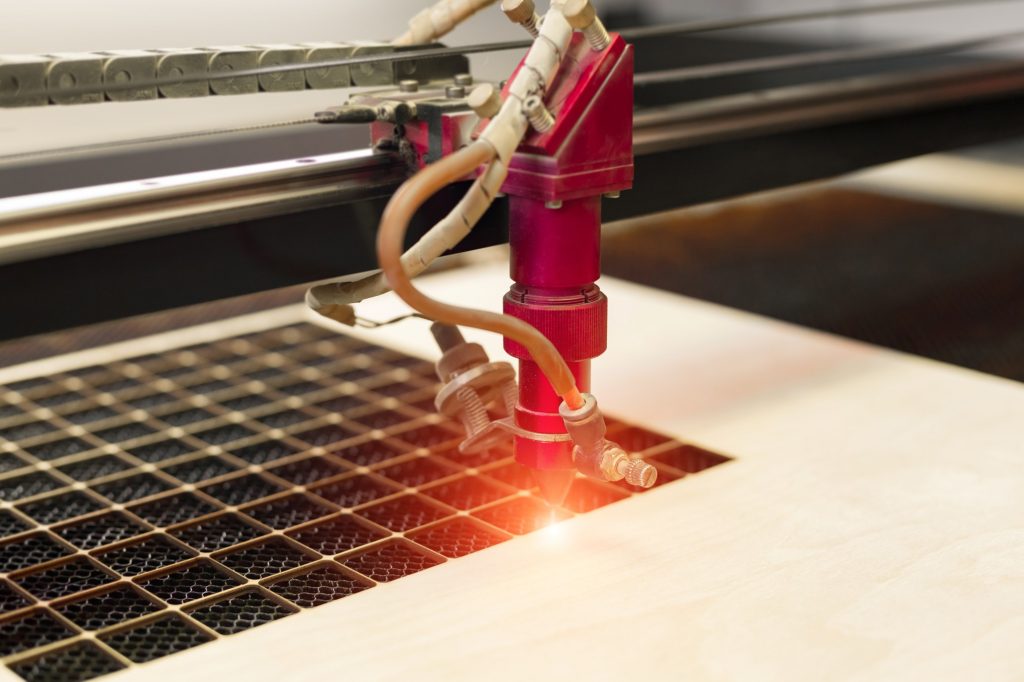

Laser cutters have revolutionized the woodworking industry, enabling intricate and precise cuts with unmatched speed and accuracy. For woodworkers seeking to create exceptional cutouts, laser cutters offer an unparalleled solution. This comprehensive guide will delve into the intricacies of laser cutters for wood cutouts, empowering you with the knowledge to make informed decisions and unlock the full potential of this transformative technology.

Table of Content

- 1 Laser Cutter for Wood Cutouts: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Understanding Laser Cutters for Wood

- 1.3 H1: Selecting the Right Laser Cutter for Wood Cutouts

- 1.4 H1: Understanding Laser Cutters for Wood

- 1.5 H1: Laser Cutter Safety and Maintenance

- 1.6 H1: Applications of Laser Cutters for Wood Cutouts

- 1.7 H1: Conclusion

- 1.8 FAQs

H1: Understanding Laser Cutters for Wood

Laser cutters utilize a highly focused laser beam to vaporize or melt materials, creating precise cuts. The laser beam is generated by a laser source, typically a CO2 or fiber laser, and directed through a series of mirrors and lenses to the cutting head. The cutting head moves along a predefined path, guided by computer-aided design (CAD) software, to create the desired cutout.

H2: Advantages of Laser Cutters for Wood

- Precision: Laser cutters deliver unparalleled precision, cutting intricate designs with sharp edges and minimal deviation.

- Speed: Laser cutting is significantly faster than traditional cutting methods, allowing for efficient production of large quantities.

- Versatility: Laser cutters can handle a wide range of wood types, from softwoods like pine to hardwoods like oak.

- Flexibility: Laser cutters can create complex shapes and designs that would be impossible or impractical to achieve with manual tools.

- Automation: Laser cutters can be programmed to perform repetitive tasks, reducing labor costs and increasing productivity.

DOWNLOAD SVG FILES FOR LASER CUTTING

H1: Selecting the Right Laser Cutter for Wood Cutouts

Laser cutters have revolutionized the woodworking industry, enabling intricate and precise cuts with unmatched speed and accuracy. For woodworkers seeking to create exceptional cutouts, laser cutters offer an unparalleled solution. This comprehensive guide will delve into the intricacies of laser cutters for wood cutouts, empowering you with the knowledge to make informed decisions and unlock the full potential of this transformative technology.

- Small Wooden Laser Cut Kits Small Wooden Laser Cut Kits: A Guide To Exquisite Craftsmanship

- 3d Wood Laser Cutter 3D Wood Laser Cutter: Revolutionizing Woodworking With Precision And Efficiency

- Wooden Laser Cut Wedding Invitations H1: Wooden Laser Cut Wedding Invitations: A Timeless And Elegant Choice For Your Special Day

- Wood Laser Cutting Wood Laser Cutting: A Comprehensive Guide To Precision And Versatility

- Wooden Laser Cut Memorial H1: Wooden Laser Cut Memorials: A Timeless Tribute To Cherished Memories

H1: Understanding Laser Cutters for Wood

H2: How Laser Cutters Work

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutters utilize a highly focused laser beam to vaporize or melt materials, creating precise cuts. The laser beam is generated by a laser source, typically a CO2 or fiber laser, and directed through a series of mirrors and lenses to the cutting head. The cutting head moves along a predefined path, guided by computer-aided design (CAD) software, to create the desired cutout.

H2: Advantages of Laser Cutters for Wood

- Laser Power: The power of the laser determines the thickness of wood that can be cut. For wood cutouts, a power of 50-100 watts is typically sufficient.

- Cutting Bed Size: The cutting bed size determines the maximum size of the cutouts that can be produced.

- Software Compatibility: Ensure that the laser cutter is compatible with your CAD software for seamless design integration.

- Ease of Use: Look for a laser cutter with intuitive software and user-friendly controls for ease of operation.

- Price: Laser cutters can range in price from a few thousand dollars to tens of thousands of dollars. Determine your budget and consider the features and capabilities you need.

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Ensure proper ventilation to remove fumes and smoke.

- Keep the laser cutter in a well-lit area to prevent accidental contact with the laser beam.

- Regularly clean the laser lens and mirrors to maintain optimal performance.

- Calibrate the laser cutter periodically to ensure accuracy.

- Replace consumables such as the laser tube and nozzle as needed.

- Wall art and decorations

- Custom furniture and fixtures

- Personalized gifts and keepsakes

- Model making

- Jewelry making

- Scrapbooking and card making

- Prototyping and manufacturing

- Signage and displays

- Packaging and product design

H2: Factors to Consider

H1: Laser Cutter Safety and Maintenance

H2: Safety Precautions

H2: Maintenance

H1: Applications of Laser Cutters for Wood Cutouts

H2: Home Decor

H2: Crafts and Hobbies

H2: Commercial Applications

H1: Conclusion

Laser cutters offer an exceptional solution for creating intricate and precise wood cutouts. By understanding the technology, selecting the right machine, adhering to safety protocols, and performing regular maintenance, woodworkers can harness the full potential of laser cutters to unlock their creativity and revolutionize their projects.

FAQs

Q: What types of wood can be cut with a laser cutter?

A: Laser cutters can cut a wide range of wood types, including hardwoods, softwoods, and plywood.

Q: How thick of wood can a laser cutter cut?

A: The thickness of wood that can be cut depends on the laser power. Most laser cutters for wood cutouts can handle thicknesses up to 1/2 inch.

Q: Is laser cutting wood safe?

A: Laser cutting wood can produce fumes and smoke, so proper ventilation is crucial. Always wear appropriate safety gear and avoid contact with the laser beam.

Q: How do I design cutouts for laser cutting?

A: Cutouts can be designed using CAD software. The design should be exported in a compatible file format for the laser cutter.

Q: What are the maintenance requirements for laser cutters?

A: Laser cutters require regular cleaning, calibration, and replacement of consumables such as the laser tube and nozzle.