Etching Wood Laser Cutter: A Comprehensive Guide to Precision Woodworking

Introduction

Laser cutting has revolutionized the woodworking industry, enabling intricate designs and precise cuts with unprecedented efficiency. Etching wood laser cutters have become an indispensable tool for hobbyists and professionals alike, offering the ability to create stunning and unique wooden creations. This comprehensive guide will delve into the world of etching wood laser cutters, exploring their capabilities, applications, and best practices.

Table of Content

- 1 Etching Wood Laser Cutter: A Comprehensive Guide to Precision Woodworking

- 1.1 Introduction

- 1.2 Understanding Etching Wood Laser Cutters

- 1.3 Applications of Etching Wood Laser Cutters

- 1.4 Understanding Etching Wood Laser Cutters

- 1.5 Types of Wood for Etching

- 1.6 Best Practices for Etching Wood

- 1.7 Conclusion

- 1.8 Frequently Asked Questions (FAQs)

Understanding Etching Wood Laser Cutters

Etching is the process of creating a design or image by engraving or burning the surface of a material. In the context of wood laser cutting, a laser beam is used to etch the surface of the wood, creating a permanent mark.

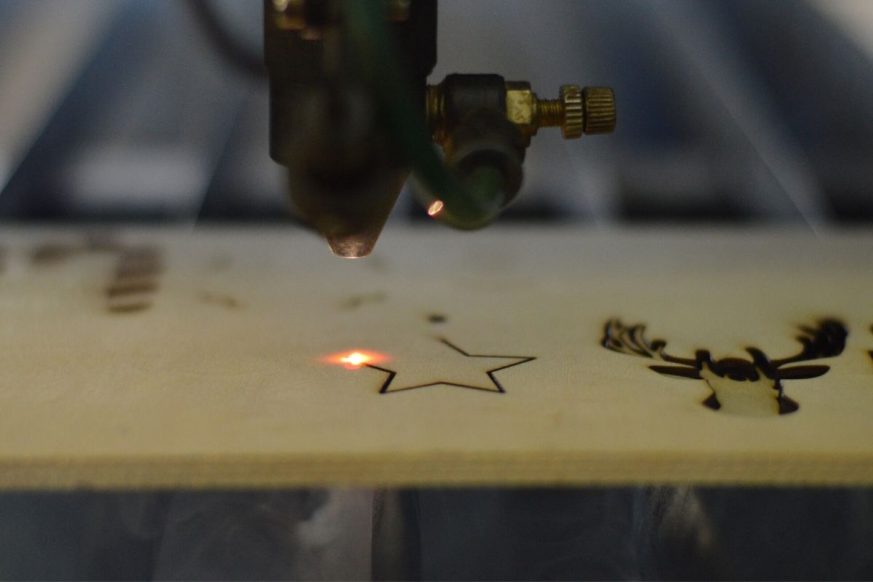

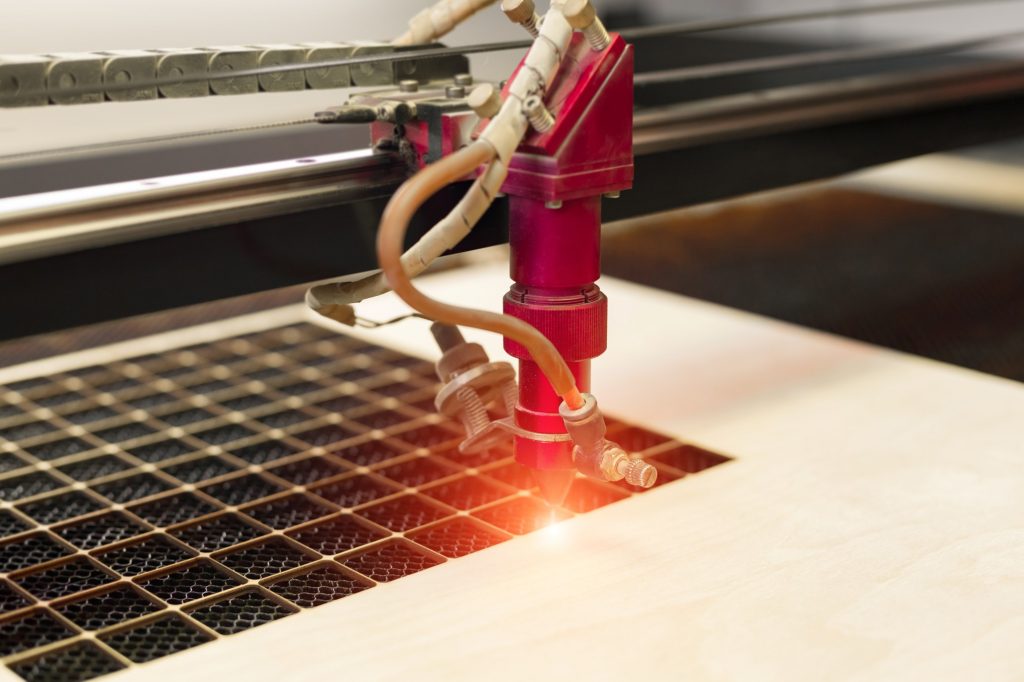

How Etching Wood Laser Cutters Work

Etching wood laser cutters utilize a laser beam to etch the surface of the wood. The laser beam is typically generated by a CO2 or fiber laser source. The laser beam is focused onto the wood surface, where it vaporizes or burns the wood, creating the desired design.

Applications of Etching Wood Laser Cutters

The applications of etching wood laser cutters are vast and varied, including:

Art and Decor: Creating intricate wall art, sculptures, and decorative pieces.

DOWNLOAD SVG FILES FOR LASER CUTTING

Signage: Producing custom signs for businesses, homes, and events.

Jewelry and Accessories: Designing unique wooden jewelry, keychains, and other accessories.

Toys and Games: Manufacturing wooden toys, puzzles, and game pieces.

Industrial Applications: Marking parts, creating prototypes, and engraving serial numbers.

Laser cutting has revolutionized the woodworking industry, enabling intricate designs and precise cuts with unprecedented efficiency. Etching wood laser cutters have become an indispensable tool for hobbyists and professionals alike, offering the ability to create stunning and unique wooden creations. This comprehensive guide will delve into the world of etching wood laser cutters, exploring their capabilities, applications, and best practices.

- Laser Cut Wooden Box Template Free H1: Laser Cut Wooden Box Template Free: Elevate Your Crafting Skills

- Laser Cut Wooden Glasses Laser Cut Wooden Glasses: A Sustainable And Stylish Accessory

- Best Laser Wood Cutter And Engraver The Ultimate Guide To Choosing The Best Laser Wood Cutter And Engraver

- Laser Cut Wooden Place Names Uk Laser Cut Wooden Place Names UK: A Comprehensive Guide

- Wooden Laser Cut Words H1: Wooden Laser Cut Words: A Versatile And Eye-Catching Embellishment

Understanding Etching Wood Laser Cutters

What is Etching?

DOWNLOAD SVG FILES FOR LASER CUTTING

Etching is the process of creating a design or image by engraving or burning the surface of a material. In the context of wood laser cutting, a laser beam is used to etch the surface of the wood, creating a permanent mark.

How Etching Wood Laser Cutters Work

Etching wood laser cutters utilize a laser beam to etch the surface of the wood. The laser beam is typically generated by a CO2 or fiber laser source. The laser beam is focused onto the wood surface, where it vaporizes or burns the wood, creating the desired design.

Types of Wood for Etching

The choice of wood for etching depends on the desired outcome. Some popular woods for etching include:

Hardwoods: Maple, oak, cherry, and walnut offer a durable and high-quality etching surface.

Softwoods: Pine, fir, and cedar are more affordable and easier to etch, but may not produce as sharp or detailed results.

Best Practices for Etching Wood

Preparation:

- Sand the wood surface to remove any imperfections or debris.

- Apply a masking material to protect the areas not to be etched.

Laser Settings:

- Adjust the laser power, speed, and focus to suit the wood type and desired etch depth.

- Test different settings on scrap wood before etching the final piece.

Post-Processing:

- Remove the masking material and clean the etched surface.

- Sand or polish the etched surface to smooth any rough edges.

- Apply a sealant to protect the etched design from moisture and damage.

Conclusion

Etching wood laser cutters offer a versatile and precise method for creating stunning wooden creations. Understanding the principles of etching, choosing the right wood, and following best practices are essential for achieving optimal results. With proper care and maintenance, an etching wood laser cutter can be a valuable tool for any woodworker, enabling the creation of intricate designs and unique pieces.

Frequently Asked Questions (FAQs)

Q: What is the difference between etching and engraving?

A: Etching involves burning or vaporizing the wood surface, while engraving cuts into the wood.

Q: Can I etch any type of wood?

A: Yes, but the results may vary depending on the wood type. Hardwoods generally produce sharper and more detailed etchings.

Q: How do I clean the etched surface?

A: Use a soft cloth or brush to gently remove any debris or residue.

Q: How can I protect the etched design?

A: Apply a clear sealant to prevent moisture and damage.