Wood Laser Cutter Frame: A Comprehensive Guide

Introduction

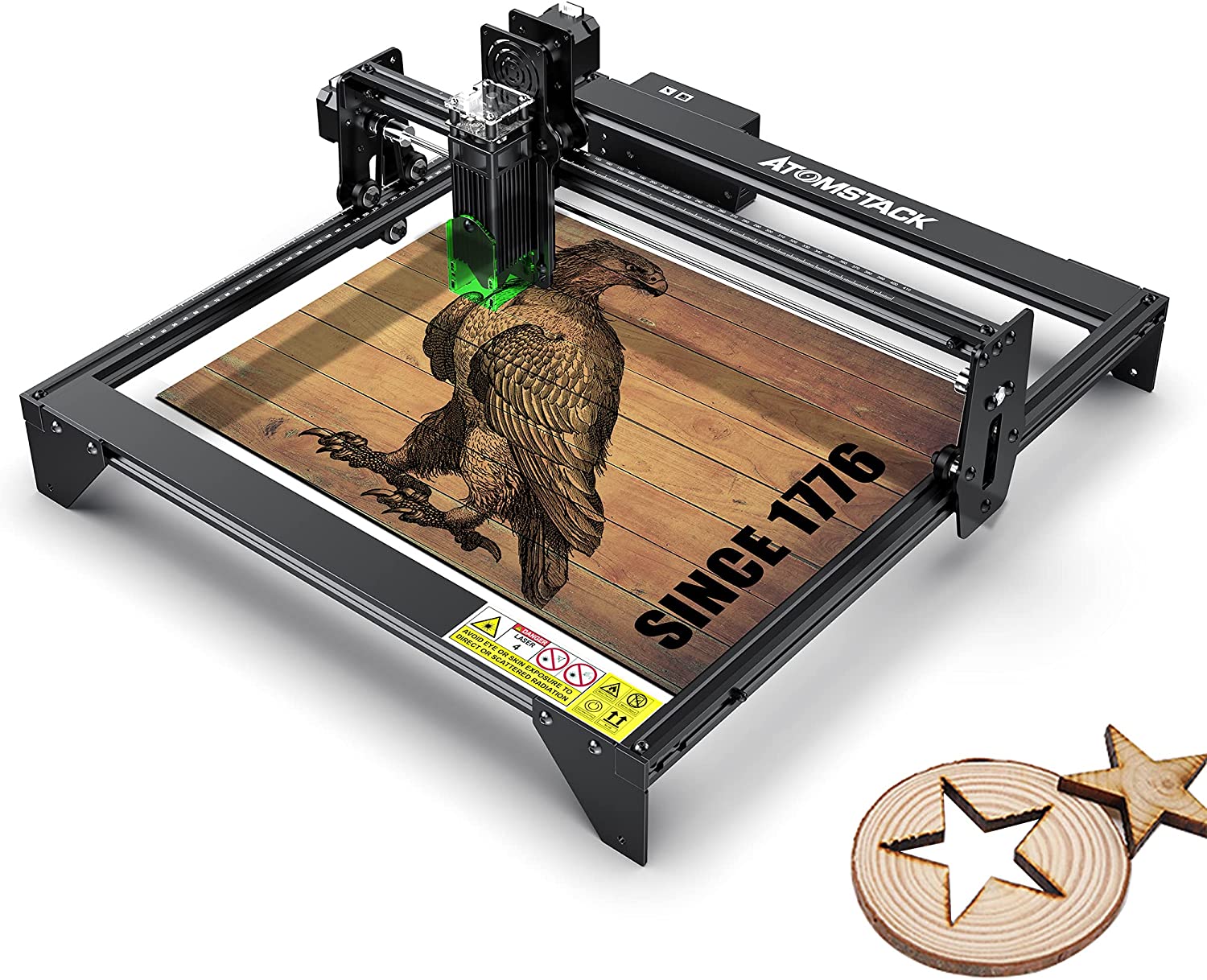

Wood laser cutters are indispensable tools for woodworking professionals, hobbyists, and makers alike. They offer precise cutting capabilities, enabling intricate designs and complex shapes to be realized with ease. However, the performance and durability of a laser cutter depend heavily on the quality of its frame. This article delves into the essential aspects of wood laser cutter frames, providing insights into their design, materials, and construction techniques.

Table of Content

H1: Design Considerations

A robust frame ensures that the laser cutter can withstand the vibrations and forces generated during the cutting process. It must provide a stable platform for the laser optics, carriage system, and workpiece.

H2: Weight Distribution

The weight of the laser cutter should be evenly distributed across the frame to prevent warping or bending. Proper weight distribution also enhances stability and reduces the risk of resonance.

H2: Access and Maintenance

The frame should allow easy access to the laser cutter’s components for maintenance, cleaning, and repairs. Removable panels or access doors facilitate these tasks without dismantling the entire machine.

H1: Materials and Construction

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Frame Materials

Common materials used for wood laser cutter frames include:

- Extruded Aluminum: Lightweight, durable, and corrosion-resistant.

- Laser Wood Cut Outs Laser Wood Cut Outs: A Comprehensive Guide To Precision And Versatility

- Laser Cut Wooden Letters Uk Laser Cut Wooden Letters UK: A Guide To Crafting Bespoke Creations

- Laser Cut Wooden Leaf Laser Cut Wooden Leaf: A Nature-Inspired Decorative Masterpiece

- Laser Wood Cut Out Laser Wood Cut Out: A Comprehensive Guide To Precision Cutting And Artistic Expression

- Wood Laser Cutter Canada Wood Laser Cutter Canada: A Comprehensive Guide To Precision Cutting Solutions

- Steel: Strong and rigid, but heavier than aluminum.

- Cast Iron: Very rigid and stable, but prone to rust.

Wood laser cutters are indispensable tools for woodworking professionals, hobbyists, and makers alike. They offer precise cutting capabilities, enabling intricate designs and complex shapes to be realized with ease. However, the performance and durability of a laser cutter depend heavily on the quality of its frame. This article delves into the essential aspects of wood laser cutter frames, providing insights into their design, materials, and construction techniques.

H1: Design Considerations

H2: Structural Integrity

DOWNLOAD SVG FILES FOR LASER CUTTING

A robust frame ensures that the laser cutter can withstand the vibrations and forces generated during the cutting process. It must provide a stable platform for the laser optics, carriage system, and workpiece.

H2: Weight Distribution

The weight of the laser cutter should be evenly distributed across the frame to prevent warping or bending. Proper weight distribution also enhances stability and reduces the risk of resonance.

H2: Construction Techniques

The frame can be constructed using various methods:

- Welding: Provides strong and permanent joints.

- Bolting: Allows for disassembly and reassembly, but may introduce some vibration.

- Machining: Precisely creates complex shapes and ensures tight tolerances.

H1: Frame Optimization

H2: Resonance Reduction

Resonance can degrade cut quality and damage the laser cutter. Optimizing the frame’s design and materials can minimize resonance by distributing forces and absorbing vibrations.

H2: Thermal Expansion Control

Wood laser cutters generate heat during operation, which can cause frame expansion. Compensating for thermal expansion ensures accurate cutting and prevents binding.

H2: Surface Treatment

Powder coating or anodizing the frame protects it from corrosion, wear, and scratches, enhancing its durability and aesthetic appeal.

H1: Conclusions

The frame of a wood laser cutter plays a critical role in its performance and longevity. By carefully considering the design, materials, and construction techniques, users can select or build a frame that meets their specific needs. A robust and well-optimized frame ensures precise cutting, minimizes vibration, and extends the laser cutter’s lifespan.

FAQs

Q: What is the best material for a wood laser cutter frame?

A: Extruded aluminum is a good choice due to its strength, durability, and corrosion resistance.

Q: How can I reduce resonance in my laser cutter frame?

A: Use damping materials, optimize the frame’s geometry, and avoid using materials that amplify vibrations.

Q: What are the benefits of powder coating a laser cutter frame?

A: Powder coating provides corrosion resistance, durability, and a professional finish.