Wood Laser Cutter Machine: The Ultimate Guide to Precision and Efficiency

Introduction

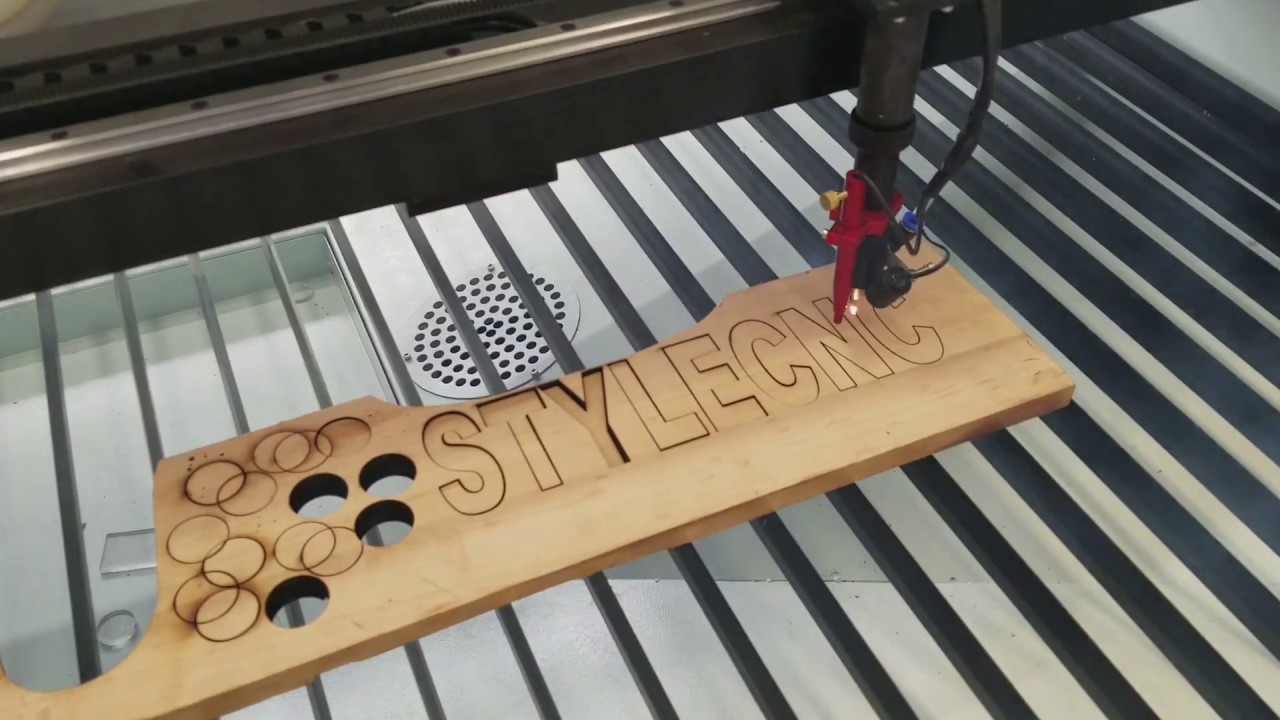

Wood laser cutter machines are revolutionizing the woodworking industry, offering unparalleled precision, efficiency, and versatility. This comprehensive guide will delve into the intricacies of wood laser cutters, empowering you to make an informed decision when purchasing one for your business or hobby.

Table of Content

- 1 Wood Laser Cutter Machine: The Ultimate Guide to Precision and Efficiency

- 2 H1: Understanding Wood Laser Cutter Technology

- 2.1 H2: Types of Wood Laser Cutters

- 3 H1: Understanding Wood Laser Cutter Technology

- 3.2 H2: How Laser Cutting Works

- 3.3 H2: Types of Wood Laser Cutters

- 4 H2: Advantages of Wood Laser Cutters

- 5 H1: Choosing the Right Wood Laser Cutter

- 5.4 H2: Factors to Consider

- 5.5 H2: Recommended Wood Laser Cutters

- 6 H1: Applications of Wood Laser Cutters

- 6.6 H2: Artistic Creations

- 6.7 H2: Industrial Applications

- 7 H1: Safety Considerations

- 7.8 H2: Essential Precautions

- 8 H1: Conclusion

- 9 FAQs

H1: Understanding Wood Laser Cutter Technology

Laser cutting is a non-contact process that utilizes a highly focused laser beam to cut through materials. The laser beam melts, vaporizes, or burns the wood, creating precise and clean cuts.

H2: Types of Wood Laser Cutters

CO2 Lasers:

- Emit a continuous beam of light at 10.6 micrometers wavelength

- Suitable for cutting a wide range of materials, including wood, acrylic, and fabric

Fiber Lasers:

- Emit a pulsed beam of light at 1.06 micrometers wavelength

- Wood Laser Cutter Cost Wood Laser Cutter Cost: A Comprehensive Guide

- Wooden Laser Cut Magnet Wooden Laser Cut Magnets: A Unique And Customizable Way To Display Your Memories

- Laser Cut Timber Laser Cut Timber: Unlocking Intricate Designs And Precision Manufacturing

- Laser Cut Wooden Lampshades Laser Cut Wooden Lampshades: Illuminating Your Space With Precision And Style

- Wooden Laser Cut Clock H1: Wooden Laser Cut Clock: A Timeless Masterpiece Of Precision And Beauty

- Offer higher cutting speeds and efficiency than CO2 lasers

- Ideal for cutting thin and reflective materials like stainless steel and aluminum

Wood laser cutter machines are revolutionizing the woodworking industry, offering unparalleled precision, efficiency, and versatility. This comprehensive guide will delve into the intricacies of wood laser cutters, empowering you to make an informed decision when purchasing one for your business or hobby.

H1: Understanding Wood Laser Cutter Technology

H2: How Laser Cutting Works

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting is a non-contact process that utilizes a highly focused laser beam to cut through materials. The laser beam melts, vaporizes, or burns the wood, creating precise and clean cuts.

H2: Types of Wood Laser Cutters

CO2 Lasers:

H2: Advantages of Wood Laser Cutters

Precision:

- Laser cutters provide unparalleled precision, cutting complex shapes and intricate designs with ease.

Speed:

- Laser cutters operate at high speeds, significantly reducing production time compared to manual methods.

Efficiency:

- Laser cutting is a non-contact process, eliminating the need for consumables like saw blades. This reduces downtime and maintenance costs.

Versatility:

- Laser cutters can cut a wide range of wood species, thicknesses, and shapes, making them suitable for various applications.

H1: Choosing the Right Wood Laser Cutter

H2: Factors to Consider

Cutting Area:

- Determine the maximum size of materials you need to cut.

Power:

- Laser power is measured in watts and determines the cutting speed and thickness of materials that can be cut.

Laser Type:

- Choose between CO2 or fiber lasers based on your specific application and budget.

Software:

- The laser cutter software controls the cutting process. Look for software that is user-friendly and offers advanced features.

H2: Recommended Wood Laser Cutters

For Beginners:

- Glowforge Basic: Compact and affordable, suitable for hobbyists and small businesses.

For Professionals:

- Epilog Zing Laser: Offers high cutting speed, precision, and a large cutting area.

- Trotec Speedy 360: State-of-the-art laser cutter with advanced features and automation options.

H1: Applications of Wood Laser Cutters

H2: Artistic Creations

- Intricate wood carvings

- Personalized gifts and home décor

- Custom signage and artwork

H2: Industrial Applications

- Furniture production

- Architectural models

- Precision engineering

H1: Safety Considerations

H2: Essential Precautions

- Wear appropriate protective gear, including laser safety glasses and gloves.

- Ensure proper ventilation to remove fumes and particles.

- Follow all manufacturer’s instructions and safety guidelines.

H1: Conclusion

Wood laser cutter machines are a game-changer for the woodworking industry. Their precision, speed, efficiency, and versatility make them an essential tool for businesses and hobbyists alike. By understanding the technology, choosing the right machine, and following safety precautions, you can unlock the full potential of wood laser cutting and elevate your woodworking projects to new heights.

FAQs

Q: What types of wood can laser cutters cut?

A: Laser cutters can cut most types of wood, including hardwoods, softwoods, plywood, and MDF.

Q: How thick of wood can laser cutters cut?

A: The thickness of wood that can be cut depends on the laser power and type. Typically, CO2 lasers can cut up to 1 inch thick wood, while fiber lasers can cut up to 0.5 inch thick wood.

Q: Are laser cutters dangerous?

A: Laser cutters can be dangerous if not used properly. It is essential to follow safety precautions, such as wearing protective gear and ensuring proper ventilation.

Q: How much do wood laser cutters cost?

A: Wood laser cutters range in price from a few thousand dollars for hobbyist models to hundreds of thousands of dollars for industrial models.