Industrial Wood Laser Cutter: Precision, Efficiency, and Versatility for Woodworking

Introduction

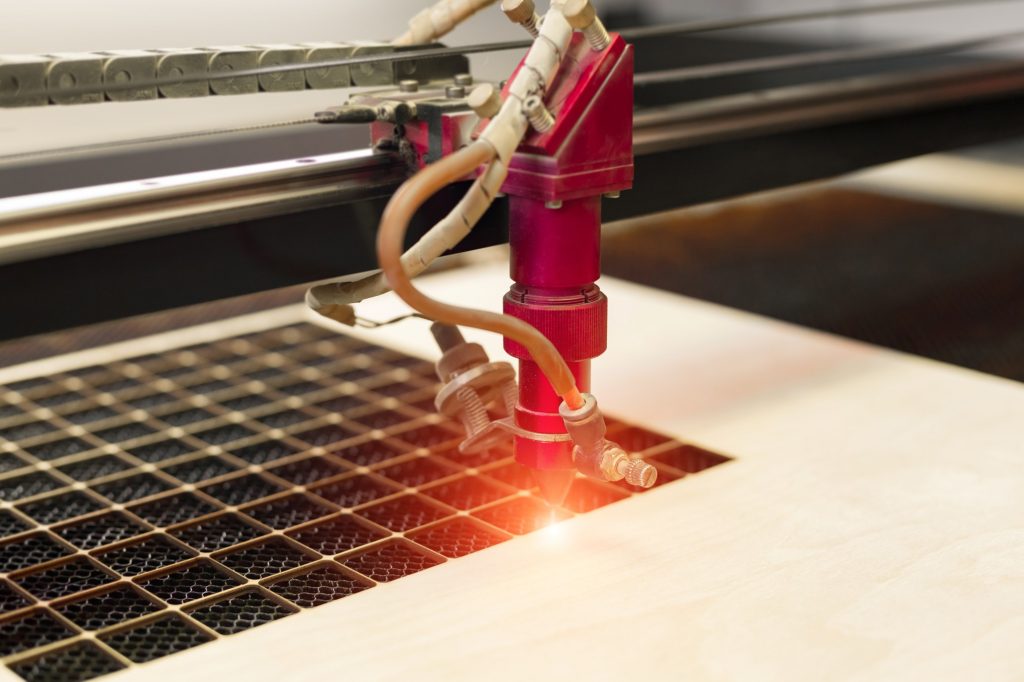

Industrial wood laser cutters have revolutionized the woodworking industry, offering unparalleled precision, efficiency, and versatility. These advanced machines employ laser technology to cut, engrave, and mark wood with unmatched accuracy and detail. In this comprehensive guide, we will explore the key features, benefits, and applications of industrial wood laser cutters, empowering you to make informed decisions for your woodworking projects.

Table of Content

- 1 Industrial Wood Laser Cutter: Precision, Efficiency, and Versatility for Woodworking

- 1.1 Introduction

- 1.2 Key Features of Industrial Wood Laser Cutters

- 1.3 Benefits of Using Industrial Wood Laser Cutters

- 1.4 Key Features of Industrial Wood Laser Cutters

- 1.5 Applications of Industrial Wood Laser Cutters

- 1.6 Conclusion

- 1.7 FAQs

Key Features of Industrial Wood Laser Cutters

Industrial wood laser cutters utilize high-power lasers, typically in the range of 50-150 watts, enabling them to cut through thick wood materials with ease.

2. Precision Cutting:

Laser cutters offer exceptional precision, producing clean and accurate cuts with minimal burrs or jagged edges. This precision allows for intricate designs and complex shapes to be cut with ease.

3. Non-Contact Cutting:

Unlike traditional cutting methods, laser cutters operate without direct contact with the wood, eliminating the risk of tool marks, scratches, or warping.

4. Versatility: DOWNLOAD SVG FILES FOR LASER CUTTING

Industrial wood laser cutters can handle a wide range of wood types, including hardwood, softwood, plywood, and MDF. They can also be used for engraving, etching, and marking.

5. Automation:

Many industrial wood laser cutters feature automated systems, such as auto-focus and material loading, which streamline production and reduce labor costs.

Benefits of Using Industrial Wood Laser Cutters

Industrial wood laser cutters have revolutionized the woodworking industry, offering unparalleled precision, efficiency, and versatility. These advanced machines employ laser technology to cut, engrave, and mark wood with unmatched accuracy and detail. In this comprehensive guide, we will explore the key features, benefits, and applications of industrial wood laser cutters, empowering you to make informed decisions for your woodworking projects.

- Laser Cut Wood Shapes Laser Cut Wood Shapes: Unleashing Creativity And Precision

- Laser Cut Wooden Open Sign Laser Cut Wooden Open Sign: A Comprehensive Guide

- Wood Design Cutting Wood Design Cutting: A Comprehensive Guide To Precision And Creativity

- Wooden Laser Cut Toys Wooden Laser Cut Toys: A Timeless And Sustainable Choice For Playful Learning

- Laser Cut Wooden Tulips Laser Cut Wooden Tulips: A Guide To Crafting Unique And Beautiful Floral Art

Key Features of Industrial Wood Laser Cutters

1. High-Power Laser Source: DOWNLOAD SVG FILES FOR LASER CUTTING

Industrial wood laser cutters utilize high-power lasers, typically in the range of 50-150 watts, enabling them to cut through thick wood materials with ease.

2. Precision Cutting:

Laser cutters offer exceptional precision, producing clean and accurate cuts with minimal burrs or jagged edges. This precision allows for intricate designs and complex shapes to be cut with ease.

1. Increased Productivity:

Laser cutters significantly increase productivity by automating cutting processes and reducing setup times. This allows for faster turnaround and higher output.

2. Enhanced Quality:

The precision cutting capabilities of laser cutters ensure consistent, high-quality cuts with minimal waste. This eliminates the need for manual finishing or sanding.

3. Reduced Operating Costs:

Laser cutters have low operating costs compared to traditional cutting methods. They consume less energy, require minimal maintenance, and have a long lifespan.

4. Customization and Flexibility:

Laser cutters enable the creation of custom designs and intricate patterns, expanding the possibilities for woodworking projects.

Applications of Industrial Wood Laser Cutters

Industrial wood laser cutters find widespread use in various woodworking applications, including:

1. Furniture Manufacturing:

Laser cutters are used to cut intricate patterns and designs for furniture components, such as chair backs, tabletops, and cabinet doors.

2. Toy Production:

Laser cutters can produce precise and detailed cuts for wooden toys, including puzzles, building blocks, and dollhouses.

3. Architectural Millwork:

Laser cutters are used to create decorative moldings, trim, and other architectural elements with intricate designs.

4. Signage and Engraving:

Laser cutters can engrave or mark wood for signage, plaques, and other decorative purposes.

5. Craft and Hobby Projects:

Laser cutters are popular among hobbyists and crafters for creating personalized gifts, home décor, and other creative projects.

Conclusion

Industrial wood laser cutters are indispensable tools for woodworking professionals and hobbyists alike. Their precision, efficiency, and versatility empower users to produce high-quality wooden products with ease. Whether you are looking to increase productivity, enhance quality, or explore new design possibilities, an industrial wood laser cutter is a valuable investment that will revolutionize your woodworking operations.

FAQs

1. What is the difference between a CO2 and a fiber laser cutter?

CO2 laser cutters are commonly used for cutting wood, while fiber laser cutters are better suited for cutting metals.

2. What are the safety considerations when using a laser cutter?

Laser cutters emit high-intensity laser beams, so proper safety precautions, such as wearing protective eyewear and enclosing the cutting area, are essential.

3. What factors should be considered when choosing an industrial wood laser cutter?

Factors to consider include laser power, cutting area, automation features, and the type of wood you will be cutting.

4. How can I maintain my industrial wood laser cutter?

Regular maintenance, including cleaning the laser optics and aligning the cutting head, is crucial for optimal performance and longevity.

5. Where can I find training on how to use an industrial wood laser cutter?

Many manufacturers offer training programs to help users learn the safe and effective operation of their laser cutters.