H1: Troubleshooting Laser Cutter Not Cutting Through Wood: A Comprehensive Guide

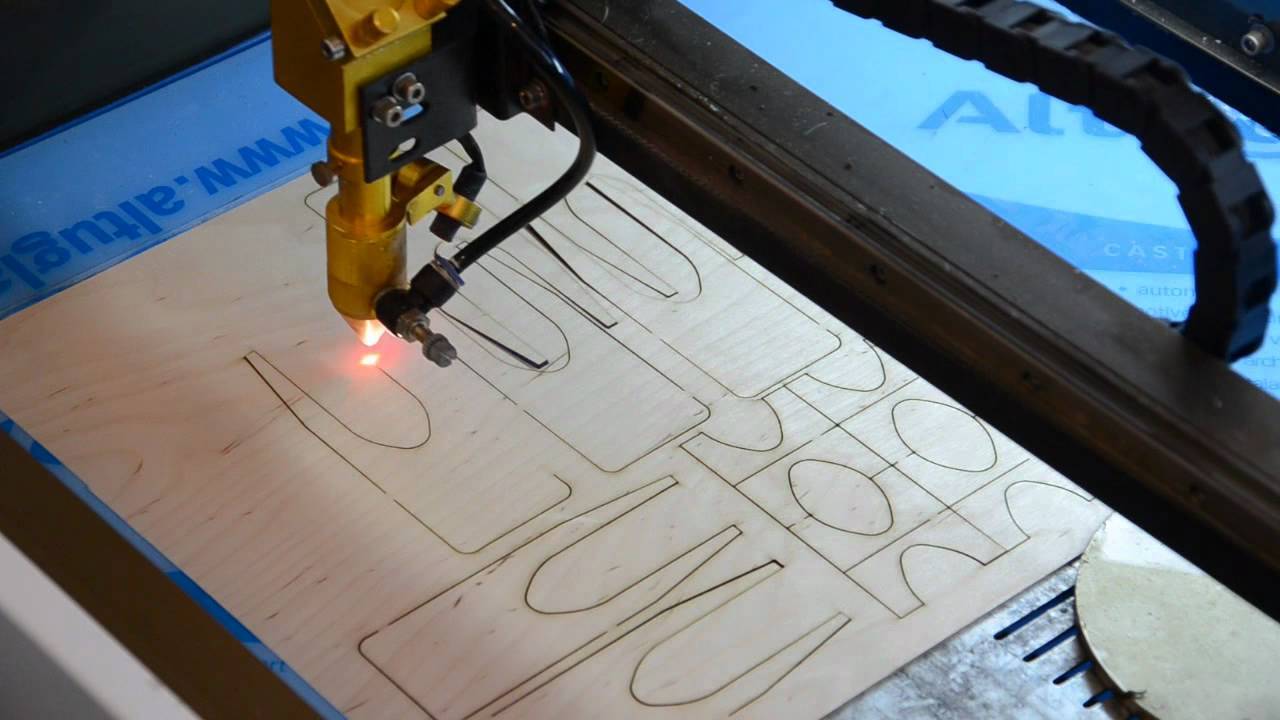

Laser cutters are versatile tools that can precisely cut and engrave a wide range of materials, including wood. However, when a laser cutter fails to cut through wood effectively, it can be frustrating and time-consuming. This article provides a comprehensive guide to troubleshooting and resolving this issue, ensuring optimal performance and productivity.

H2: Common Causes of Laser Cutter Not Cutting Through Wood

Table of Content

- 1 H1: Troubleshooting Laser Cutter Not Cutting Through Wood: A Comprehensive Guide

- 2 H2: Common Causes of Laser Cutter Not Cutting Through Wood

- 2.1 H3: Inadequate Laser Power

- 2.2 H3: Incorrect Focus Distance

- 2.3 H3: Dull or Damaged Optics

- 3 H2: Common Causes of Laser Cutter Not Cutting Through Wood

- 3.4 H3: Inadequate Laser Power

- 3.5 H3: Material Thickness Too Thick

- 3.6 H3: Poor Airflow

- 4 H3: Other Factors to Consider

- 5 H2: Troubleshooting and Resolution

- 5.7 H3: Step-by-Step Guide

- 6 H3: Tips for Optimal Performance

- 7 H3: Conclusion

- 8 H2: Frequently Asked Questions (FAQs)

- 8.8 Q: Why is my laser cutter not cutting through wood at all?

- 8.9 Q: How do I know if the laser power is too low?

- 8.10 Q: How can I ensure the correct focus distance?

- 8.11 Q: How often should I clean the optics of my laser cutter?

- 8.12 Q: Can I cut any type of wood with my laser cutter?

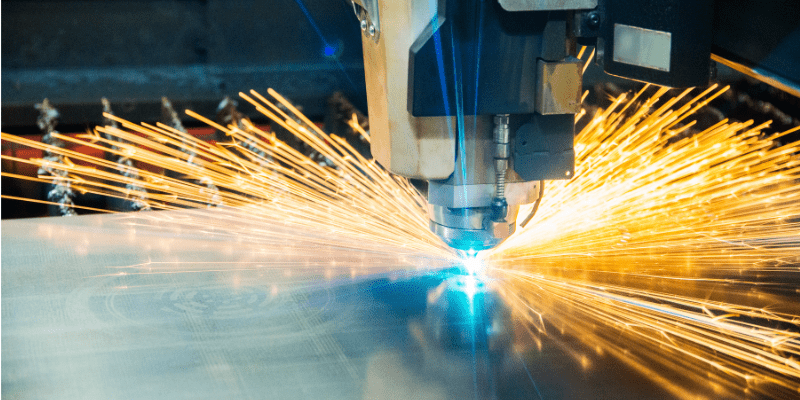

H3: Inadequate Laser Power

H3: Incorrect Focus Distance

- Cause: The laser beam is not focused at the correct distance from the wood surface.

- Solution: Adjust the focus distance until the beam produces a sharp, concentrated spot on the wood.

DOWNLOAD SVG FILES FOR LASER CUTTING

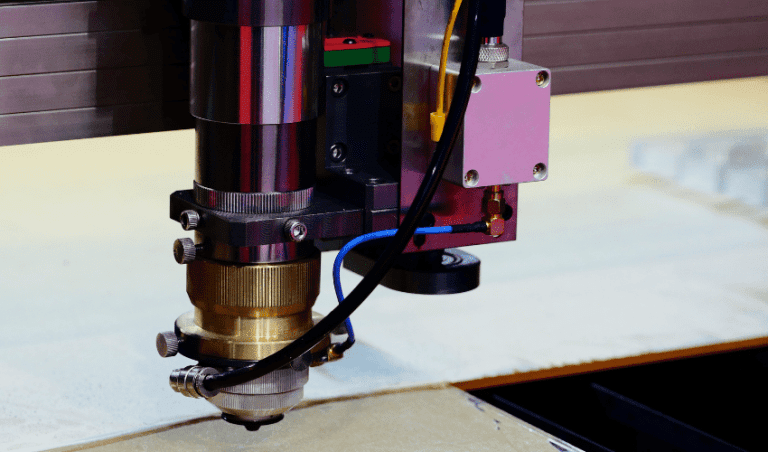

H3: Dull or Damaged Optics

- Laser Cut Wooden Jewelry Laser Cut Wooden Jewelry: A Unique And Sustainable Statement

- Wood Laser Cutter Price Wood Laser Cutter Price: A Comprehensive Guide To Costs And Considerations

- Wooden Laser Cut Magnet Wooden Laser Cut Magnets: A Unique And Customizable Way To Display Your Memories

- Large Wood Laser Cutter Large Wood Laser Cutter: The Ultimate Guide For Woodworking Professionals

- Laser Cutter Cutting Wood Laser Cutter Cutting Wood: A Comprehensive Guide

- Cause: Insufficient laser power to penetrate the wood’s thickness.

- Solution: Increase the laser power settings or upgrade to a laser cutter with higher wattage.

- Cause: Dirty, scratched, or misaligned lenses and mirrors can scatter the laser beam and reduce its power.

- Solution: Clean or replace the optics regularly and ensure proper alignment.

H2: Common Causes of Laser Cutter Not Cutting Through Wood

H3: Inadequate Laser Power

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Material Thickness Too Thick

- Cause: The laser cutter is not capable of cutting through wood of the specified thickness.

- Solution: Use thinner wood or consider a laser cutter with a higher cutting capacity.

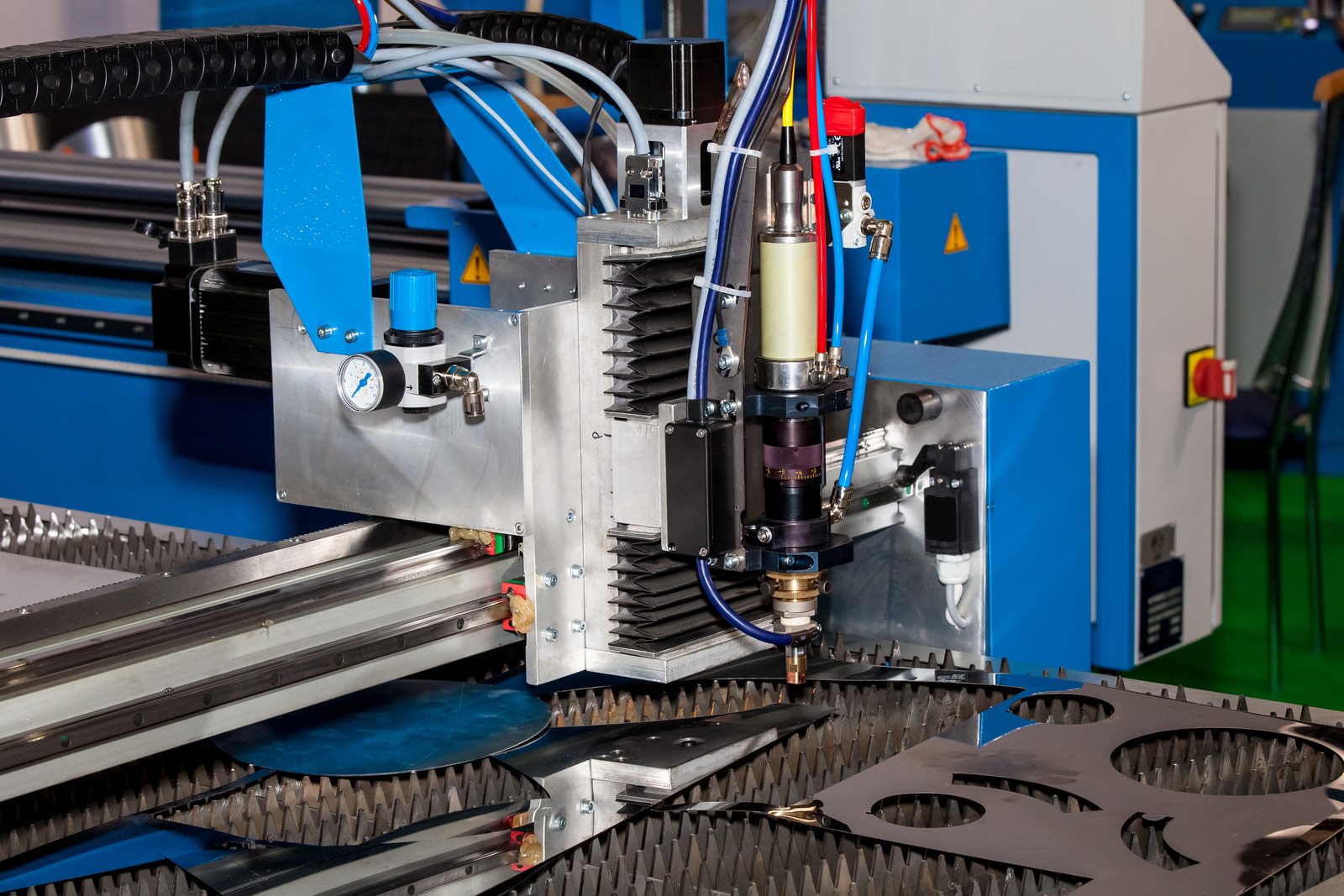

H3: Poor Airflow

- Cause: Insufficient airflow can lead to smoke and debris accumulation, which can block the laser beam.

- Solution: Ensure proper ventilation by cleaning the exhaust system and using an air assist to clear the cutting area.

H3: Other Factors to Consider

- Wood Type: Different types of wood have varying densities and hardness, affecting the cutting efficiency.

- Laser Wavelength: The wavelength of the laser beam can influence its absorption and cutting capabilities.

- Cutting Speed: Too fast or too slow cutting speeds can compromise cut quality and penetration depth.

- Software Settings: Ensure that the laser cutting software is properly configured with the correct power, speed, and focus settings for the specific wood type and thickness.

H2: Troubleshooting and Resolution

H3: Step-by-Step Guide

- Check Laser Power: Adjust the laser power to the recommended settings or higher if necessary.

- Adjust Focus Distance: Use a focus gauge or ruler to set the optimal focus distance.

- Clean and Inspect Optics: Clean or replace any dirty or damaged lenses and mirrors.

- Verify Material Thickness: Ensure that the wood thickness is within the cutting capacity of the laser cutter.

- Improve Airflow: Clean the exhaust system and use an air assist to enhance smoke and debris removal.

- Adjust Cutting Parameters: Fine-tune the cutting speed, power, and focus settings based on the wood type and thickness.

H3: Tips for Optimal Performance

- Calibrate Regularly: Regularly calibrate the laser cutter to ensure accurate power and focus.

- Use High-Quality Materials: Choose wood with consistent density and free from knots or imperfections.

- Optimize Cutting Path: Design cutting paths to minimize laser travel and avoid sharp corners or intricate designs.

- Monitor Cut Quality: Regularly inspect the cut edges to identify any deviations or inconsistencies.

- Seek Professional Help: If the issue persists, consider consulting a qualified laser cutter technician for expert assistance.

H3: Conclusion

Laser cutters are powerful tools that require proper maintenance and optimization to ensure effective cutting performance. By understanding the common causes and following the troubleshooting steps outlined in this article, users can identify and resolve issues when a laser cutter fails to cut through wood. By addressing these factors and implementing best practices, users can achieve optimal cut quality, productivity, and longevity from their laser cutters.

H2: Frequently Asked Questions (FAQs)

Q: Why is my laser cutter not cutting through wood at all?

A: The most likely causes are inadequate laser power, incorrect focus distance, or dull or damaged optics.

Q: How do I know if the laser power is too low?

A: If the laser beam leaves a faint or barely visible mark on the wood, the power is likely insufficient.

Q: How can I ensure the correct focus distance?

A: Use a focus gauge or ruler to measure the distance between the laser nozzle and the wood surface. Adjust the distance until the beam forms a sharp, concentrated spot.

Q: How often should I clean the optics of my laser cutter?

A: Regular cleaning is essential to prevent dirt and debris from accumulating. Clean the lenses and mirrors after every few hours of operation or as needed.

Q: Can I cut any type of wood with my laser cutter?

A: The cutting capacity of a laser cutter depends on its wattage and wavelength. Check the manufacturer’s specifications to determine the types of wood that can be cut.