Wood Printing Laser Cutter: A Comprehensive Guide to Precision Engraving

Introduction

Wood printing laser cutters have revolutionized the field of woodworking, enabling precise and intricate engraving on wooden surfaces. These machines utilize focused laser beams to etch designs, patterns, and text onto wood, creating stunning and durable results. In this comprehensive guide, we will explore the world of wood printing laser cutters, from their types and features to their applications and benefits.

Table of Content

- 1 Wood Printing Laser Cutter: A Comprehensive Guide to Precision Engraving

- 1.1 Introduction

- 1.2 Types of Wood Printing Laser Cutters

- 1.3 Types of Wood Printing Laser Cutters

- 1.4 Features to Consider

- 1.5 Applications of Wood Printing Laser Cutters

- 1.6 Benefits of Using Wood Printing Laser Cutters

- 1.7 How to Choose the Right Wood Printing Laser Cutter

- 1.8 Conclusion

- 1.9 FAQs

Types of Wood Printing Laser Cutters

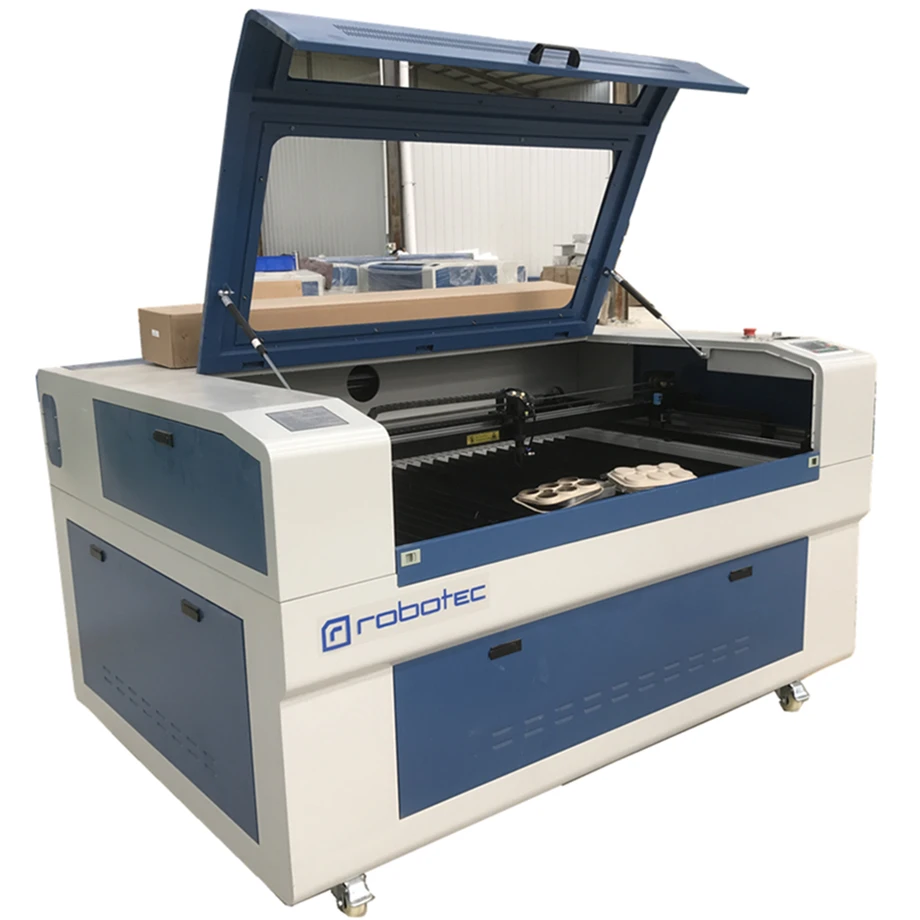

1. CO2 Laser Cutters:

- Emit a continuous laser beam at a wavelength of 10.64 μm

- Capable of cutting and engraving a wide range of materials, including wood

- Offer high precision and cutting speed

- Relatively expensive compared to other types

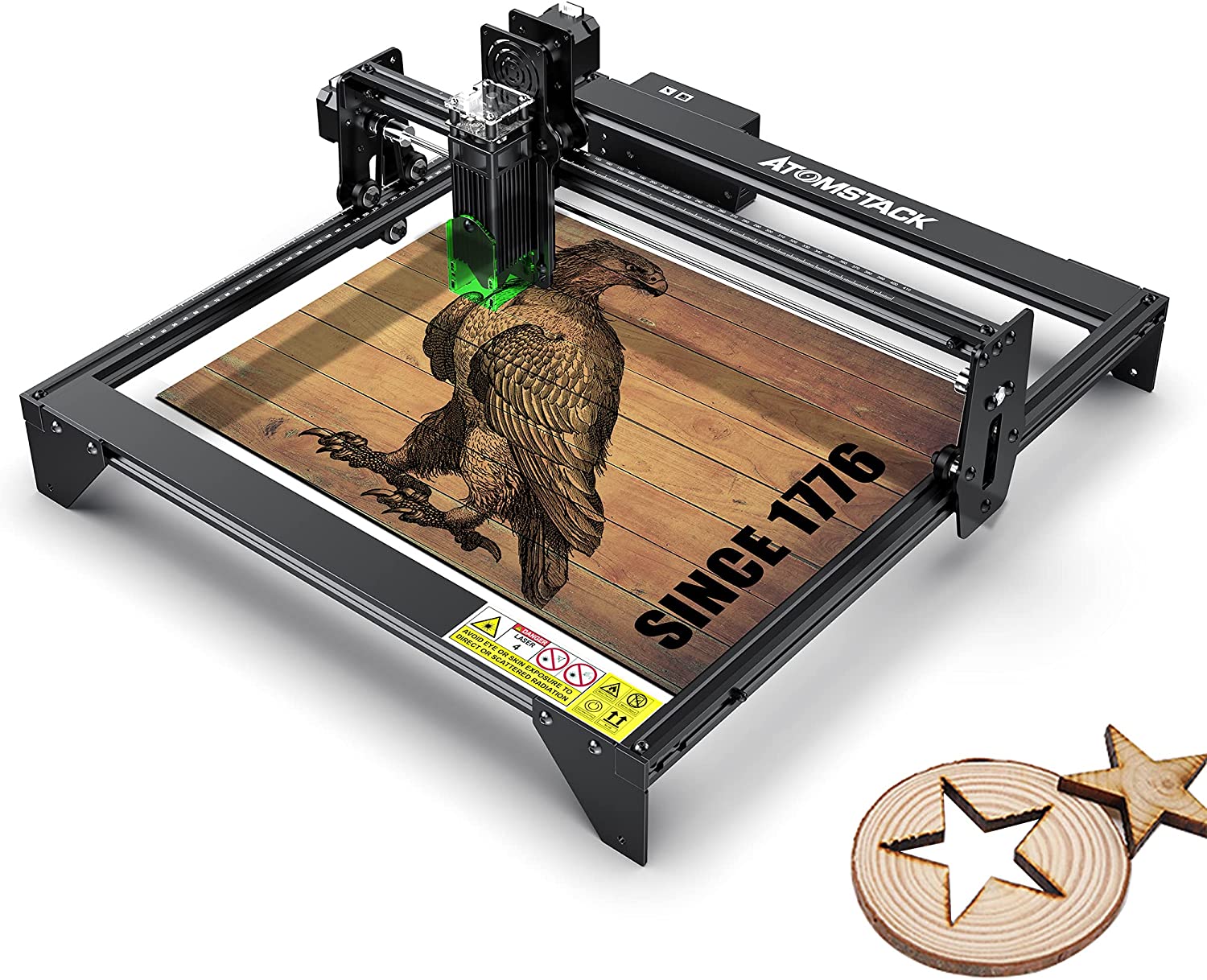

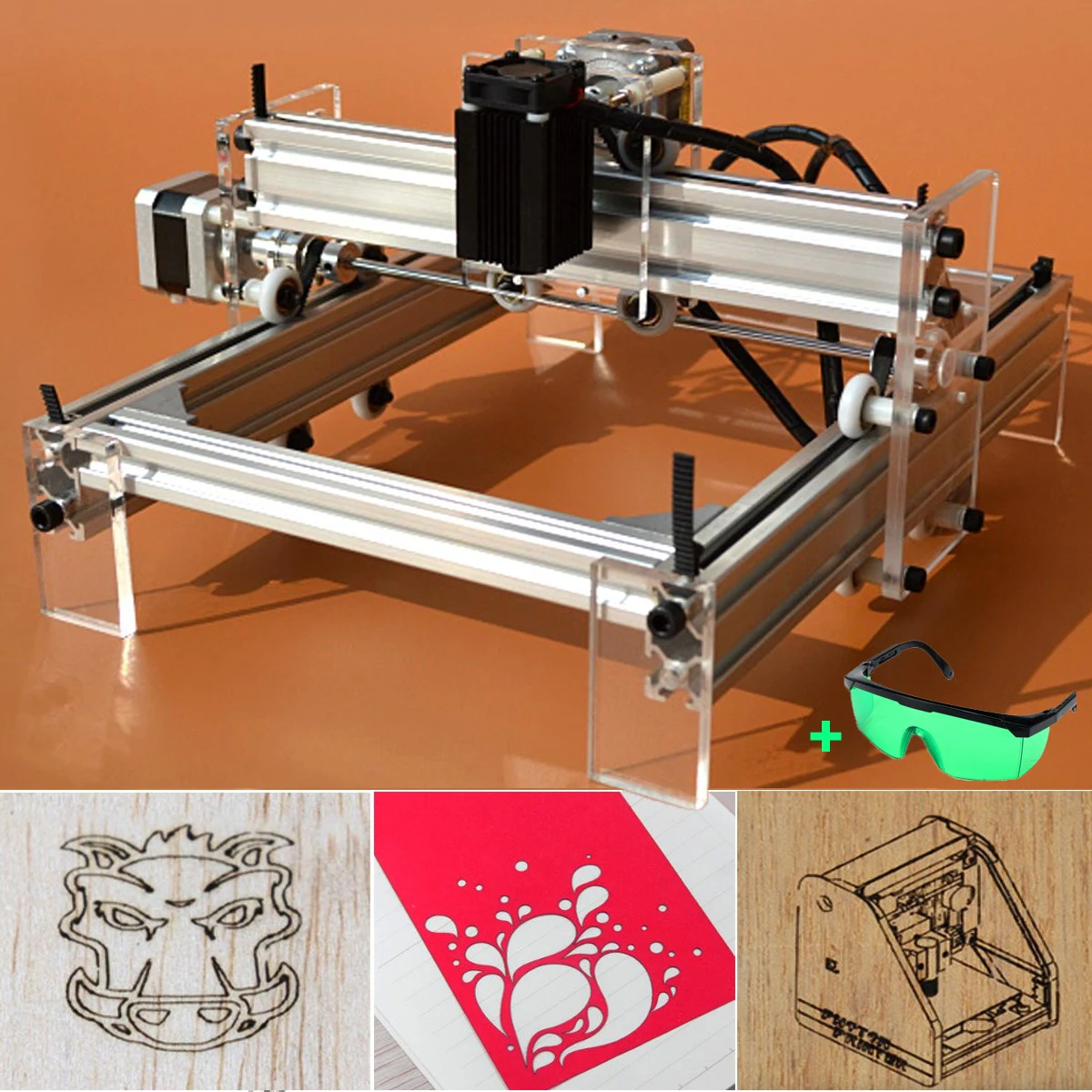

2. Diode Laser Cutters:

- Use semiconductor diodes to generate a laser beam

- Wooden Laser Cut Model Kits H1: Unlocking The World Of Wooden Laser Cut Model Kits: A Comprehensive Guide

- Wooden Laser Cut Clouds Wooden Laser Cut Clouds: An Ethereal Touch To Your Decor

- Can Laser Cutter Cut Wood Can Laser Cutter Cut Wood? A Comprehensive Guide

- Laser Etching Wood Laser Etching Wood: A Comprehensive Guide To Precision And Creativity

- Laser Cut Thick Wood Laser Cutting Thick Wood: A Comprehensive Guide

- Emit a continuous laser beam at a wavelength of 10.64 μm

- Smaller and more portable than CO2 laser cutters

- Less powerful and suitable for engraving rather than cutting

- Affordable option for hobbyists and small businesses

- Employ a fiber optic cable to deliver the laser beam

- Compact and energy-efficient

- Produce high-quality engravings with minimal thermal distortion

- More expensive than CO2 laser cutters

- Hardwoods like oak and maple produce crisp and detailed engravings.

- Sand the surface smooth and remove any dust or debris.

- Raster engraving creates images based on dots, while vector engraving uses lines and curves.

- Use a fume extraction system and ensure proper ventilation.

- Clean the lens and mirrors regularly, and follow the manufacturer’s maintenance instructions.

Wood printing laser cutters have revolutionized the field of woodworking, enabling precise and intricate engraving on wooden surfaces. These machines utilize focused laser beams to etch designs, patterns, and text onto wood, creating stunning and durable results. In this comprehensive guide, we will explore the world of wood printing laser cutters, from their types and features to their applications and benefits.

Types of Wood Printing Laser Cutters

Laser cutters for wood engraving come in various types, each with its own advantages and drawbacks:

DOWNLOAD SVG FILES FOR LASER CUTTING

1. CO2 Laser Cutters:

3. Fiber Laser Cutters:

Features to Consider

When selecting a wood printing laser cutter, consider the following features:

1. Laser Power: Measured in watts (W), determines the depth and speed of engraving

2. Bed Size: The area available for engraving, important for larger projects

3. Engraving Speed: The rate at which the laser moves, affecting productivity

4. Resolution: The fineness of the engraving, measured in dots per inch (DPI)

5. Software: User-friendly software simplifies design and control of the machine

6. Safety Features: Includes enclosed work area, fume extraction system, and emergency stop button

Applications of Wood Printing Laser Cutters

Wood printing laser cutters find numerous applications in various industries:

1. Furniture and Home Decor: Creating intricate designs on furniture, picture frames, and decorative items

2. Signage and Advertising: Producing durable and eye-catching signs, logos, and promotional materials

3. Crafts and Hobbies: Engraving personalized gifts, jewelry, and other small-scale projects

4. Industrial Applications: Marking and labeling wood products, creating prototypes, and manufacturing components

Benefits of Using Wood Printing Laser Cutters

1. Precision and Accuracy: Laser cutters offer unmatched precision, ensuring consistent and detailed engravings

2. Versatility: Can engrave a wide range of wood species, from softwoods to hardwoods

3. Durability: Engraved designs are permanent and resistant to wear and tear

4. Efficiency: Laser cutting is a fast and automated process, increasing productivity

5. Cost-Effectiveness: Can reduce material waste and labor costs compared to traditional engraving methods

How to Choose the Right Wood Printing Laser Cutter

To choose the best wood printing laser cutter for your needs, consider the following factors:

1. Budget: Determine your available budget and explore machines that fit within it

2. Application: Identify the specific engraving tasks you need to perform

3. Material Thickness: Choose a machine with sufficient laser power to cut or engrave the wood thickness you require

4. Software: Ensure the software is compatible with your design software and easy to use

5. Support: Look for manufacturers who provide technical support and after-sales service

Conclusion

Wood printing laser cutters are powerful tools that open up endless possibilities for creating stunning and durable engravings on wood. With a wide range of types, features, and applications, these machines cater to both hobbyists and professionals alike. By carefully considering the factors discussed in this guide, you can choose the ideal laser cutter for your specific needs and embark on the journey of precision wood engraving.

FAQs

1. What is the best wood species for laser engraving?

2. How do I prepare wood for laser engraving?

3. What is the difference between raster and vector engraving?

4. How can I prevent smoke and fumes during laser engraving?

5. How do I maintain my laser cutter?