Laser Cutter Wood: Where to Buy and Essential Factors to Consider

Introduction

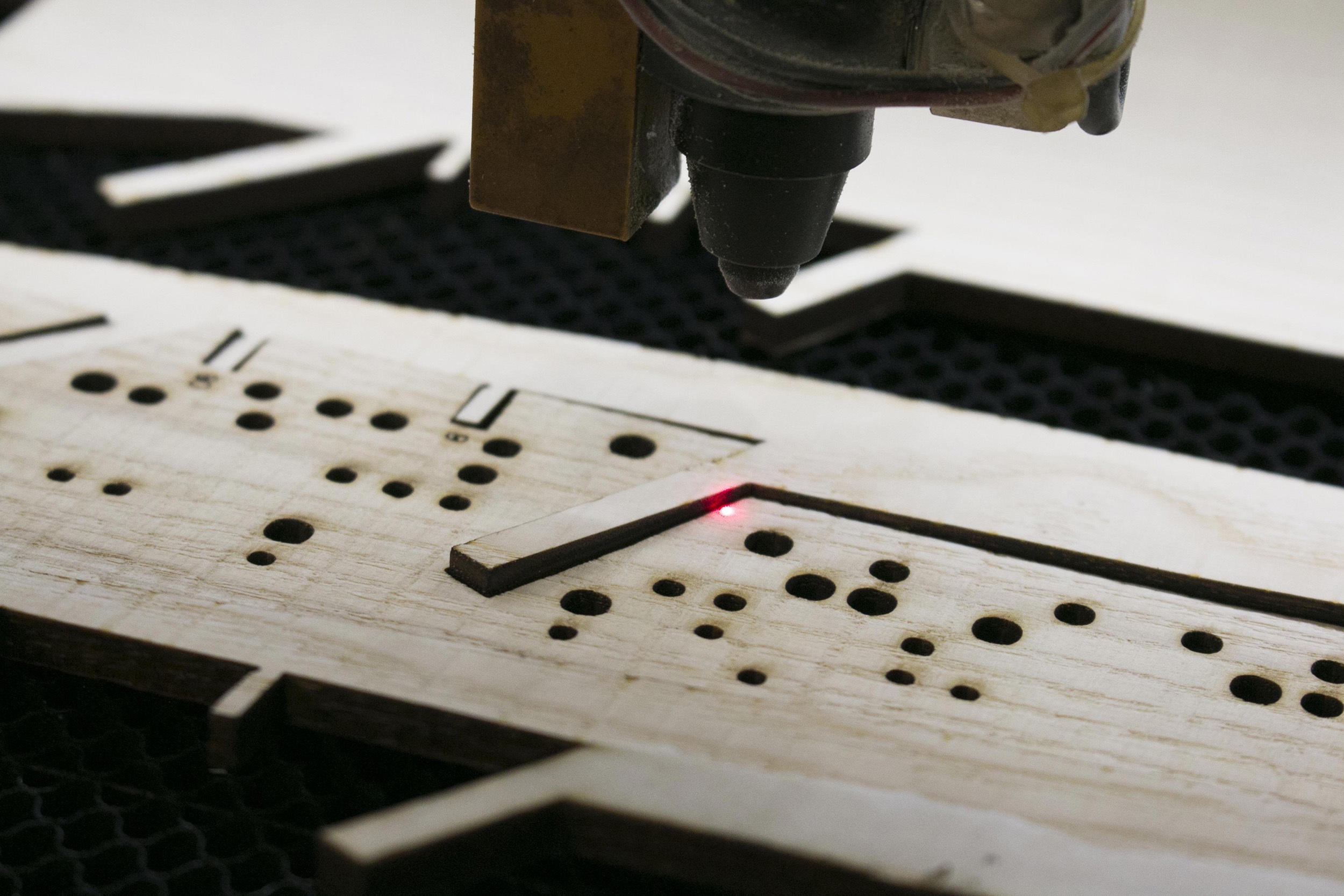

Laser cutting has revolutionized the woodworking industry, enabling precise, intricate, and efficient fabrication of wooden components. With the growing popularity of laser cutting technology, the demand for high-quality laser cutter wood has surged. This article provides a comprehensive guide to help you make informed decisions about where to buy laser cutter wood, considering essential factors such as species, thickness, grain orientation, and surface quality.

Table of Content

- 1 Laser Cutter Wood: Where to Buy and Essential Factors to Consider

- 1.1 Introduction

- 1.2 H1: Where to Buy Laser Cutter Wood

- 1.3 H2: Local Hardware Stores

- 1.4 H1: Where to Buy Laser Cutter Wood

- 1.5 H2: Online Retailers

- 1.6 H3: Specialty Wood Suppliers

- 1.7 H1: Essential Factors to Consider

- 1.8 H2: Species

- 1.9 H2: Thickness

- 1.10 H3: Grain Orientation

- 1.11 H2: Surface Quality

- 1.12 H1: Conclusion

- 1.13 FAQs

H1: Where to Buy Laser Cutter Wood

- Amazon: A vast marketplace offering a wide selection of laser cutter wood in various species and thicknesses.

- Johnson Plastics Plus: Specializes in laser-engraving materials, including laser cutter wood, with excellent customer support.

- McMaster-Carr: Industrial supplier with a large inventory of laser cutter wood, including exotic species and specialized sizes.

- US Laser: Dedicated laser cutting equipment and materials supplier, providing high-quality laser cutter wood.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Local Hardware Stores

- Home Depot: Carries a limited selection of laser cutter wood, primarily in common species and thicknesses.

- Lowe’s: Similar to Home Depot, offering a basic range of laser cutter wood options.

- Laser Cut Wooden Leaf Laser Cut Wooden Leaf: A Nature-Inspired Decorative Masterpiece

- Wood Laser Cut Wood Laser Cut: A Comprehensive Guide To Precision Crafting

- Laser Cutting Wooden Lamp Laser Cutting Wooden Lamp: A Comprehensive Guide

- Wood Laser Cutter Machine Price Wood Laser Cutter Machine Price: A Comprehensive Guide

- Wooden Laser Cut Easter Basket H1: Elevate Your Easter Celebrations With A Wooden Laser Cut Easter Basket: A Timeless Keepsake

- Amazon: A vast marketplace offering a wide selection of laser cutter wood in various species and thicknesses.

- Johnson Plastics Plus: Specializes in laser-engraving materials, including laser cutter wood, with excellent customer support.

- Local Lumberyards: May specialize in specific species or sizes of laser cutter wood, providing tailored recommendations.

- Exotic Woods: Offers a wide variety of exotic and domestic laser cutter wood species, including rare and premium options.

- Woodcraft: A leading supplier of woodworking materials, including laser cutter wood with a focus on high-quality finishing.

- Rockler: Specializes in woodworking tools and supplies, providing a curated selection of laser cutter wood for specific applications.

- Hardwoods: Durable, denser woods like maple, oak, and walnut, suitable for intricate cuts and fine details.

- Softwoods: Less dense woods like pine, cedar, and fir, easier to cut but may exhibit more burn marks.

- Plywood: Layers of thin wood veneers, offering strength and stability for larger projects.

- Thin Woods (1/16" – 1/4"): Ideal for delicate cuts, engraving, and inlay work.

- Medium Woods (1/4" – 1/2"): Versatile thickness for a wide range of applications, including signs, toys, and furniture components.

- Thick Woods (1/2" – 1"): Suitable for structural components, cutting boards, and outdoor projects requiring durability.

- Edge Grain: Wood grain runs parallel to the surface, resulting in a smooth finish with less splintering.

- Flat Grain: Wood grain runs perpendicular to the surface, creating a more rustic and textured look.

- Quarter Grain: A combination of edge and flat grain, offering a balance of durability and aesthetics.

- Sanded: Pre-sanded wood with a smooth surface, reducing the need for additional finishing.

- Unsanded: Raw wood that requires sanding before laser cutting to achieve a clean and precise cut.

- Clear: Wood with minimal knots, blemishes, or imperfections, ideal for intricate cuts and visible applications.

- Knotty: Wood with natural knots and imperfections, adding character and a rustic appeal.

Laser cutting has revolutionized the woodworking industry, enabling precise, intricate, and efficient fabrication of wooden components. With the growing popularity of laser cutting technology, the demand for high-quality laser cutter wood has surged. This article provides a comprehensive guide to help you make informed decisions about where to buy laser cutter wood, considering essential factors such as species, thickness, grain orientation, and surface quality.

H1: Where to Buy Laser Cutter Wood

H2: Online Retailers

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Specialty Wood Suppliers

H1: Essential Factors to Consider

H2: Species

H2: Thickness

H3: Grain Orientation

H2: Surface Quality

H1: Conclusion

Choosing the right laser cutter wood is crucial for successful and high-quality laser cutting projects. By considering the essential factors discussed in this article, you can make informed decisions about where to buy laser cutter wood and select the most suitable material for your specific needs. Whether you’re a seasoned professional or just starting out with laser cutting, this guide will help you find the perfect wood for your next project.

FAQs

Q: What is the best species of wood for laser cutting?

A: Hardwoods like maple, oak, and walnut offer durability and fine detail cuts.

Q: What thickness of wood should I use for laser cutting?

A: The thickness depends on the project; thinner woods (1/16" – 1/4") are suitable for delicate cuts, while thicker woods (1/2" – 1") are ideal for structural components.

Q: How do I choose the right grain orientation for laser cutting?

A: Edge grain provides a smooth finish, flat grain creates a textured look, and quarter grain offers a balance of both.

Q: Can I laser cut unsanded wood?

A: Yes, but sanding before laser cutting is recommended for a clean and precise cut.

Q: Where can I buy laser cutter wood in exotic species?

A: Specialty wood suppliers like Exotic Woods offer a wide selection of exotic laser cutter wood species.