Laser Wood Cutter Video: A Comprehensive Guide to Laser Cutting Technology

Introduction

Laser wood cutters have revolutionized the woodworking industry, providing a precise and efficient method for cutting, engraving, and shaping wood. With their versatility and ease of use, laser wood cutters have become indispensable tools for hobbyists, makers, and professional woodworkers alike. This article will delve into the world of laser wood cutters, exploring their features, benefits, and applications.

Table of Content

- 1 Laser Wood Cutter Video: A Comprehensive Guide to Laser Cutting Technology

- 1.1 Introduction

- 1.2 H1: Understanding Laser Wood Cutters

- 1.3 H2: Features and Benefits of Laser Wood Cutters

- 1.4 H1: Understanding Laser Wood Cutters

- 1.5 H1: Applications of Laser Wood Cutters

- 1.6 H1: Choosing the Right Laser Wood Cutter

- 1.7 H1: Getting Started with Laser Wood Cutting

- 1.8 H1: Troubleshooting Common Issues

- 1.9 H1: Conclusion

- 1.10 FAQs

H1: Understanding Laser Wood Cutters

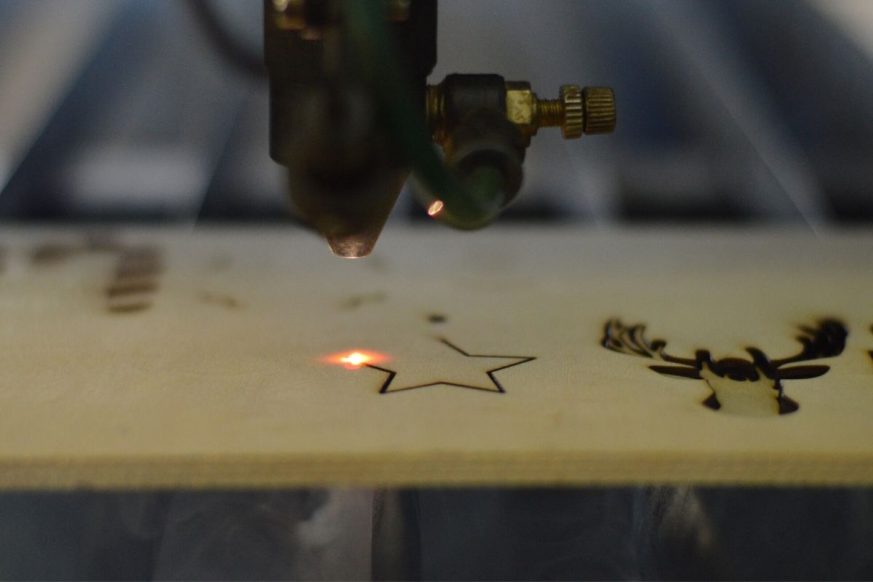

Laser wood cutters use a high-powered laser beam to cut or engrave wood. The laser is focused through a lens and directed onto the wood surface. The concentrated beam of light vaporizes or burns the wood, creating precise cuts or engravings.

H2: Types of Laser Wood Cutters

There are two main types of laser wood cutters:

- CO2 Laser Cutters: These use carbon dioxide gas to generate the laser beam. They are suitable for cutting and engraving a wide range of wood materials, including plywood, MDF, and hardwoods.

- Diode Laser Cutters: These use a semiconductor diode to generate the laser beam. They are more compact and affordable than CO2 lasers but are less powerful and suitable for cutting thinner materials.

H2: Features and Benefits of Laser Wood Cutters

H3: Precision and Accuracy

Laser wood cutters offer exceptional precision and accuracy, allowing for intricate cuts and engravings with minimal deviation. The laser beam can cut with a tolerance of a few thousandths of an inch, ensuring precise results.

Laser wood cutters have revolutionized the woodworking industry, providing a precise and efficient method for cutting, engraving, and shaping wood. With their versatility and ease of use, laser wood cutters have become indispensable tools for hobbyists, makers, and professional woodworkers alike. This article will delve into the world of laser wood cutters, exploring their features, benefits, and applications.

- Laser Cutter For Balsa Wood Laser Cutter For Balsa Wood: A Comprehensive Guide

- Wooden Laser Cut Menu H1: Elevate Your Dining Experience With Wooden Laser Cut Menus: A Comprehensive Guide

- Wood 3d Laser Engraving Wood 3D Laser Engraving: A Comprehensive Guide

- Wood Laser Cutter Templates Wood Laser Cutter Templates: The Ultimate Guide

- Laser Cutter Wood Thickness Laser Cutter Wood Thickness: A Comprehensive Guide

H1: Understanding Laser Wood Cutters

H2: How Laser Wood Cutters Work

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser wood cutters use a high-powered laser beam to cut or engrave wood. The laser is focused through a lens and directed onto the wood surface. The concentrated beam of light vaporizes or burns the wood, creating precise cuts or engravings.

H2: Types of Laser Wood Cutters

There are two main types of laser wood cutters:

H3: Versatility

Laser wood cutters can cut, engrave, and mark a wide variety of materials, including wood, acrylic, leather, and fabric. This versatility makes them ideal for various applications, from hobby projects to industrial manufacturing.

H3: Non-Contact Cutting

Unlike traditional cutting methods, laser wood cutters do not require direct contact with the material. This eliminates the risk of tool damage, reduces material deformation, and allows for cutting complex shapes.

H3: Speed and Efficiency

Laser wood cutters operate at high speeds, significantly reducing production time compared to manual or CNC methods. They can cut through multiple layers of material simultaneously, increasing efficiency.

H3: Minimal Waste

Laser cutting produces minimal waste as the laser beam vaporizes or burns the wood. This results in reduced material consumption and lower environmental impact.

H1: Applications of Laser Wood Cutters

H2: Hobby and DIY Projects

Laser wood cutters are ideal for hobbyists and DIY enthusiasts who want to create custom projects, such as toys, models, and home décor items. They offer precise cutting and engraving capabilities, allowing for intricate designs and personalized creations.

H2: Industrial Manufacturing

Laser wood cutters are used in various industrial applications, including:

- Furniture Manufacturing: Cutting and engraving intricate designs on furniture components.

- Architectural Models: Creating scale models of buildings and structures.

- Packaging: Cutting and scoring cardboard for packaging boxes and displays.

- Sign Making: Engraving and cutting signs, plaques, and awards.

H2: Art and Design

Laser wood cutters have become a popular tool for artists and designers, enabling them to create unique and intricate pieces:

- Wood Art: Engraving and cutting patterns, textures, and designs into wood for decorative purposes.

- Jewelry Making: Cutting and engraving wood for jewelry components.

- Sculpture: Creating three-dimensional sculptures and models from wood.

H1: Choosing the Right Laser Wood Cutter

H2: Factors to Consider

When choosing a laser wood cutter, consider the following factors:

- Type of Material: Determine the types of materials you plan to cut or engrave.

- Cutting Thickness: Consider the maximum thickness of material you need to cut.

- Laser Power: The laser power determines the speed and efficiency of cutting.

- Cutting Area: Choose a cutting area that meets your project requirements.

- Software Compatibility: Ensure the laser cutter is compatible with your design software.

H1: Getting Started with Laser Wood Cutting

H2: Safety Precautions

Laser wood cutting involves working with high-powered lasers. Always follow safety precautions:

- Wear protective glasses and clothing.

- Keep the work area well-ventilated.

- Never leave the laser cutter unattended.

H2: Design and Preparation

- Create your design using a compatible design software.

- Import your design into the laser cutter software.

- Set the appropriate cutting parameters based on the material and thickness.

H2: Cutting and Engraving

- Place the wood material on the cutting bed.

- Align the laser beam with the desired cutting path.

- Start the cutting or engraving process.

- Monitor the progress and make adjustments as needed.

H1: Troubleshooting Common Issues

H2: Laser Not Cutting Cleanly

- Check the laser power settings and adjust as necessary.

- Clean the laser lens and mirrors.

- Ensure the material is securely held in place.

H2: Material Burns or Scorches

- Reduce the laser power or cutting speed.

- Use a lower-power laser setting for engraving.

- Ensure the material is clean and free of moisture.

H2: Cuts Not Accurate

- Check the alignment of the laser beam.

- Calibrate the laser cutter regularly.

- Use high-quality materials with consistent thickness.

H1: Conclusion

Laser wood cutters are versatile and powerful tools that have revolutionized woodworking. Their precision, speed, and efficiency make them ideal for various applications, from hobby projects to industrial manufacturing. By understanding the principles, features, and applications of laser wood cutters, you can unlock the potential of this transformative technology.

FAQs

Q: What is the difference between a CO2 laser cutter and a diode laser cutter?

A: CO2 laser cutters are more powerful and suitable for cutting thicker materials, while diode laser cutters are more compact and affordable but less powerful.

Q: What safety precautions should I take when using a laser wood cutter?

A: Always wear protective glasses and clothing, keep the work area well-ventilated, and never leave the laser cutter unattended.

Q: How do I clean the laser lens and mirrors?

A: Use a soft, lint-free cloth and isopropyl alcohol to gently clean the lens and mirrors. Avoid touching the surfaces directly.

Q: What materials can I cut or engrave with a laser wood cutter?

A: Laser wood cutters can cut or engrave a wide range of materials, including wood, acrylic, leather, and fabric.