Wood Cutting Laser: A Comprehensive Guide

Introduction

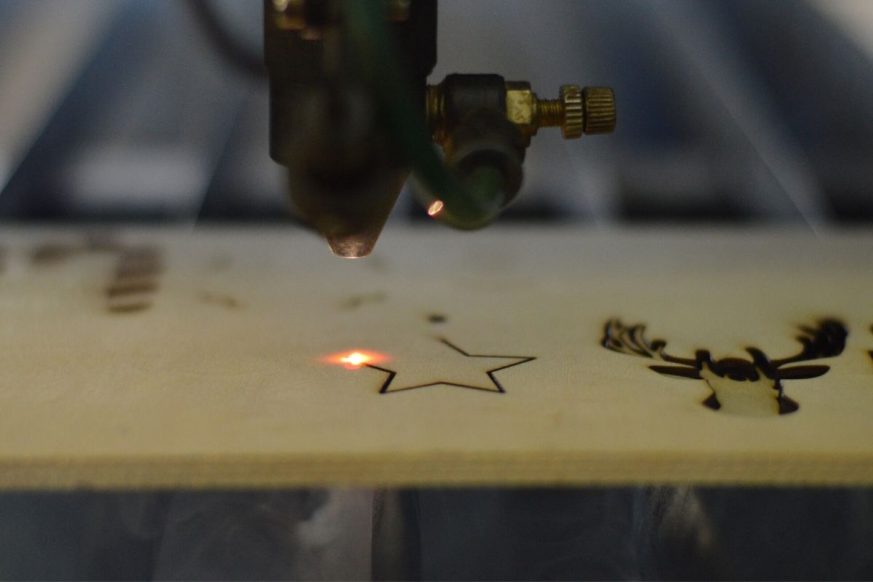

Wood cutting lasers are versatile tools that have revolutionized the woodworking industry. They offer precision, speed, and efficiency, making them ideal for a wide range of applications, from intricate designs to mass production. This article provides a comprehensive guide to wood cutting lasers, covering their types, capabilities, advantages, and uses.

Table of Content

- 1 Wood Cutting Laser: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Types of Wood Cutting Lasers

- 1.3 Types of Wood Cutting Lasers

- 1.4 Capabilities of Wood Cutting Lasers

- 1.5 Advantages of Wood Cutting Lasers

- 1.6 Applications of Wood Cutting Lasers

- 1.7 Considerations for Choosing a Wood Cutting Laser

- 1.8 Safety Precautions for Wood Cutting Lasers

- 1.9 Conclusion

- 1.10 Frequently Asked Questions (FAQs)

Types of Wood Cutting Lasers

1. CO2 Lasers:

- Emit a wavelength of 10.6 µm

- Generate high power (up to 15 kW)

- Produce clean, precise cuts with minimal heat-affected zone

- Suitable for cutting thin to medium-thickness wood

2. Fiber Lasers:

- Emit a wavelength of 1.06 µm

- Laser Cut Wooden Animals Laser Cut Wooden Animals: A Guide To Crafting Intricate And Personalized Creations

- Wood Laser Cutter For Sale Cape Town Wood Laser Cutter For Sale Cape Town: A Comprehensive Guide

- Laser Cut Wooden Football Laser Cut Wooden Football: An Intricate Art Form

- Wood Laser Cutter Files Wood Laser Cutter Files: A Comprehensive Guide To Designing And Cutting

- Fiber Laser On Wood Fiber Laser On Wood: A Comprehensive Guide

- Emit a wavelength of 10.6 µm

- Generate lower power (typically up to 4 kW)

- Provide faster cutting speeds and higher energy efficiency

- Ideal for cutting thicker wood and metals

- Precision Cutting: Lasers can cut intricate designs with high accuracy and repeatability.

- Speed: Laser cutting is significantly faster than traditional methods, allowing for mass production.

- Versatility: Lasers can cut various wood types, including hardwoods, softwoods, and plywood.

- Flexibility: Laser cutting systems can be programmed to cut different shapes, sizes, and patterns.

- Non-Contact Cutting: Lasers do not physically touch the wood, eliminating tool wear and tear.

- Improved Quality: Lasers produce clean, burr-free cuts with minimal splintering.

- Increased Efficiency: Laser cutting is faster and more efficient than manual or mechanical methods.

- Reduced Waste: Laser cutting minimizes material waste by following precise cutting paths.

- Automation: Laser cutting systems can be automated, reducing labor costs and increasing productivity.

- Versatility: Lasers can be used for a wide range of applications, from prototyping to production.

- Furniture Making: Cutting intricate designs on furniture components, such as carvings and veneers.

- Musical Instrument Manufacturing: Creating precise cuts on guitar bodies, necks, and other components.

- Toy Making: Cutting shapes and patterns for wooden toys and puzzles.

- Signage and Display: Producing custom signs, displays, and logos from wood.

- Architectural Applications: Cutting decorative panels, moldings, and other architectural elements.

- Power: Determine the required power based on the wood thickness and desired cutting speed.

- Wavelength: CO2 lasers are suitable for thin to medium-thickness wood, while fiber lasers excel at cutting thicker wood.

- Speed: Consider the cutting speed required for your specific applications.

- Accuracy: Ensure the laser system meets the desired precision and tolerance levels.

- Software: Choose a system with intuitive software that simplifies programming and operation.

- Laser Safety Glasses: Wear laser safety glasses to protect eyes from harmful laser radiation.

- Ventilation: Ensure proper ventilation to remove smoke and fumes generated during laser cutting.

- Fire Safety: Keep a fire extinguisher nearby and follow proper fire safety protocols.

- Electrical Safety: Ground the laser system properly and follow all electrical safety guidelines.

- Training: Receive proper training on the safe operation and maintenance of the laser system.

Wood cutting lasers are versatile tools that have revolutionized the woodworking industry. They offer precision, speed, and efficiency, making them ideal for a wide range of applications, from intricate designs to mass production. This article provides a comprehensive guide to wood cutting lasers, covering their types, capabilities, advantages, and uses.

Types of Wood Cutting Lasers

There are primarily two types of wood cutting lasers:

DOWNLOAD SVG FILES FOR LASER CUTTING

1. CO2 Lasers:

Capabilities of Wood Cutting Lasers

Wood cutting lasers offer a range of capabilities that make them suitable for diverse applications:

Advantages of Wood Cutting Lasers

Compared to traditional cutting methods, wood cutting lasers offer several advantages:

Applications of Wood Cutting Lasers

Wood cutting lasers are used in various industries, including:

Considerations for Choosing a Wood Cutting Laser

When choosing a wood cutting laser, consider the following factors:

Safety Precautions for Wood Cutting Lasers

Working with wood cutting lasers requires adherence to strict safety precautions:

Conclusion

Wood cutting lasers are transformative tools that enhance precision, speed, and efficiency in the woodworking industry. They offer a range of capabilities and advantages, making them suitable for various applications, from intricate designs to mass production. By understanding the types, capabilities, and considerations involved, businesses can choose the most appropriate wood cutting laser for their specific needs. Adhering to safety precautions is crucial for the safe and effective operation of these systems.

Frequently Asked Questions (FAQs)

1. What is the difference between CO2 and fiber lasers for wood cutting?

CO2 lasers offer higher power and are better suited for thin to medium-thickness wood, while fiber lasers provide faster cutting speeds and are more suitable for thicker wood.

2. How does a wood cutting laser work?

A laser beam is focused onto the wood surface, creating heat that vaporizes the wood and produces a clean cut.

3. What are the advantages of using a wood cutting laser?

Improved quality, increased efficiency, reduced waste, automation, and versatility.

4. What industries use wood cutting lasers?

Furniture making, musical instrument manufacturing, toy making, signage and display, and architectural applications.

5. What safety precautions should be taken when using a wood cutting laser?

Wear laser safety glasses, ensure ventilation, keep a fire extinguisher nearby, follow electrical safety guidelines, and receive proper training.