Shapeways Laser Cutting: A Comprehensive Guide to Advanced Manufacturing

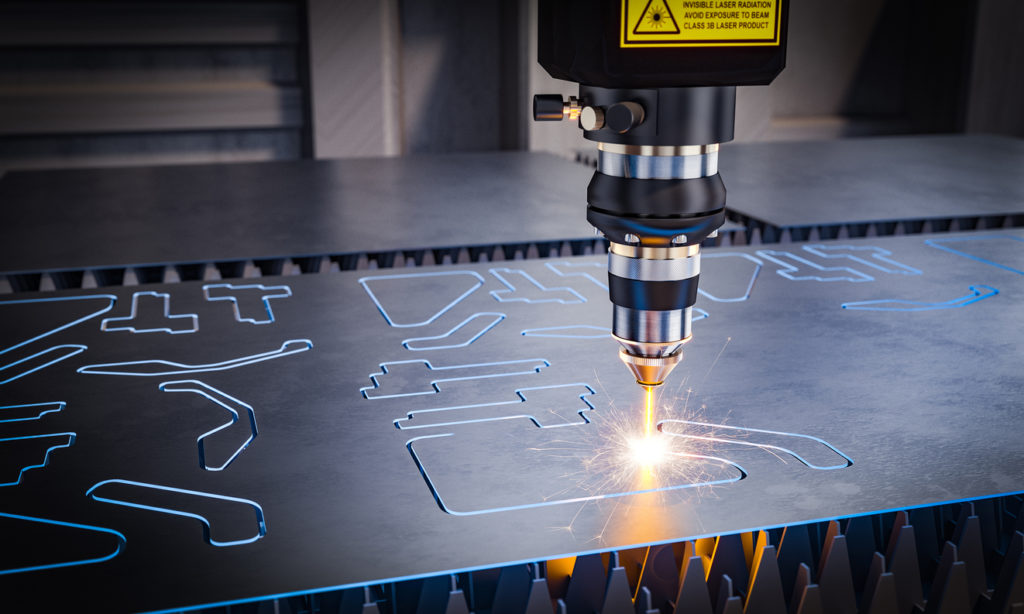

Laser cutting is a precise and versatile manufacturing technique that has revolutionized prototyping and production processes across industries. Shapeways, a leading provider of digital manufacturing services, offers a state-of-the-art laser cutting service that empowers designers and engineers to bring their ideas to life with unparalleled accuracy and efficiency.

What is Shapeways Laser Cutting?

Table of Content

Shapeways Laser Cutting utilizes advanced laser technology to cut precise shapes from a wide range of materials, including:

The laser cutting process involves focusing a high-powered laser beam onto the material, melting or vaporizing it to create intricate shapes and designs. This technology enables the production of complex parts with high precision, smooth edges, and minimal waste.

Advantages of Shapeways Laser Cutting

Shapeways Laser Cutting offers numerous advantages over traditional manufacturing methods, including:

- Precision and Accuracy: Laser cutting produces parts with exceptional precision and accuracy, allowing for intricate designs and tight tolerances.

- Speed and Efficiency: The laser cutting process is fast and efficient, reducing lead times and increasing productivity.

- Laser Cutter Comparable To Glowforge Laser Cutter Comparable To Glowforge: A Comprehensive Guide

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide To Precision Fabrication

- Thingiverse Laser Cut Thingiverse Laser Cut: Unleashing The Power Of Digital Fabrication

- Metals: Stainless steel, aluminum, titanium, and more

- Plastics: ABS, nylon, polycarbonate, and more

- Wood: Plywood, MDF, and more

- Material Versatility: Shapeways offers a wide range of materials for laser cutting, enabling the production of parts for various applications.

- Design Flexibility: Laser cutting allows for the creation of complex and customized designs that are difficult to achieve with other manufacturing methods.

- Cost-Effectiveness: Laser cutting is a cost-effective solution for both prototyping and production, reducing tooling and setup costs.

- Aerospace: Lightweight and durable components for aircraft and spacecraft

- Automotive: Precision parts for engines, transmissions, and interiors

- Medical: Implants, surgical instruments, and medical devices

- Consumer Electronics: Enclosures, buttons, and other components

- Jewelry: Intricate designs for necklaces, earrings, and bracelets

- Upload Your Design: Import your 3D model into Shapeways’ online platform.

- Select Material and Thickness: Choose the material and thickness that best suits your application.

- Specify Cutting Parameters: Define the desired laser power, speed, and other cutting parameters.

- Place Your Order: Submit your order and track its progress online.

What is Shapeways Laser Cutting?

Shapeways Laser Cutting utilizes advanced laser technology to cut precise shapes from a wide range of materials, including:

Applications of Shapeways Laser Cutting

Shapeways Laser Cutting finds applications in a vast array of industries, including:

How to Use Shapeways Laser Cutting

To utilize Shapeways Laser Cutting, follow these steps:

Shapeways offers a range of design guidelines and resources to assist users in optimizing their laser cutting projects.

FAQs

1. What is the maximum size for laser cutting?

Shapeways Laser Cutting offers a maximum cutting area of 12" x 24" (305 mm x 610 mm).

2. What is the minimum thickness for laser cutting?

The minimum thickness varies depending on the material. For example, stainless steel can be cut as thin as 0.005" (0.13 mm).

3. Can I laser cut my own designs?

Yes, Shapeways allows users to upload their own 3D models for laser cutting.

4. What is the turnaround time for laser cutting?

Turnaround time depends on the complexity of the design and the material used. Typical lead times range from 5-10 business days.

5. Can I get a quote for laser cutting?

Yes, Shapeways provides instant online quotes for laser cutting projects.

Conclusion

Shapeways Laser Cutting is a powerful and versatile manufacturing tool that empowers designers and engineers to innovate and create with unprecedented precision and efficiency. Its wide range of materials, design flexibility, and cost-effectiveness make it an ideal solution for prototyping and production in various industries. By leveraging Shapeways Laser Cutting, businesses can reduce lead times, improve product quality, and gain a competitive advantage.