3D Laser Cutter Printer: A Comprehensive Guide to Advanced Fabrication Technology

Introduction

3D laser cutter printers, also known as laser engravers or laser cutters, are revolutionizing the world of manufacturing, prototyping, and hobbyist projects. By harnessing the power of laser technology, these machines enable precise cutting, engraving, and marking on a wide range of materials, including wood, acrylic, metal, and leather. This guide delves into the intricacies of 3D laser cutter printers, exploring their capabilities, applications, and key considerations for choosing the right model.

Table of Content

- 1 3D Laser Cutter Printer: A Comprehensive Guide to Advanced Fabrication Technology

- 1.1 Introduction

- 1.2 H1: Understanding 3D Laser Cutter Printers

- 1.3 H3: Types of Laser Cutter Printers

- 1.4 H2: Applications of 3D Laser Cutter Printers

- 1.5 H1: Understanding 3D Laser Cutter Printers

- 1.6 H2: How Laser Cutter Printers Work

- 1.7 H3: Types of Laser Cutter Printers

- 1.8 H1: Choosing the Right 3D Laser Cutter Printer

- 1.9 H2: Key Considerations

- 1.10 H2: Recommended Models

- 1.11 H1: Conclusion

- 1.12 FAQs

H1: Understanding 3D Laser Cutter Printers

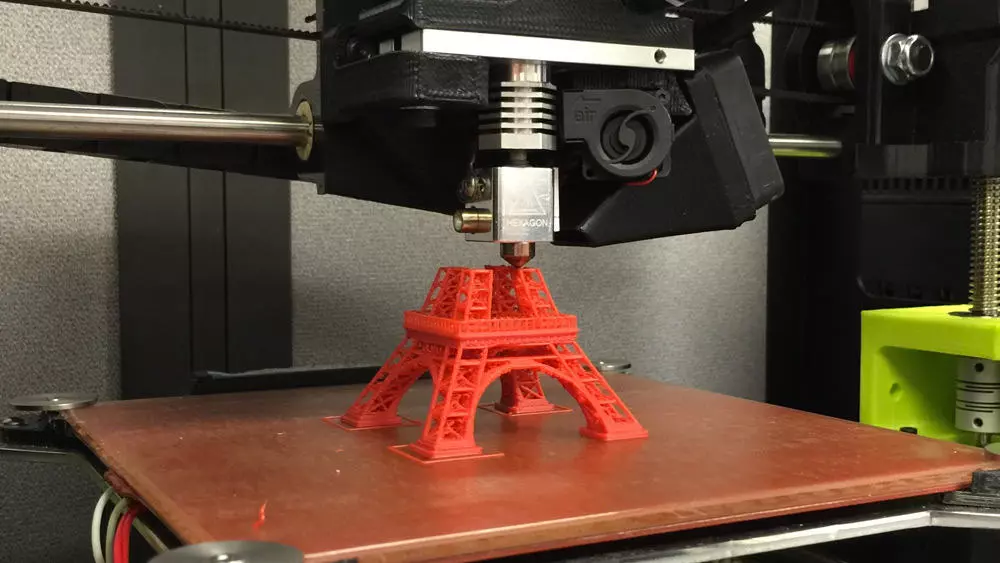

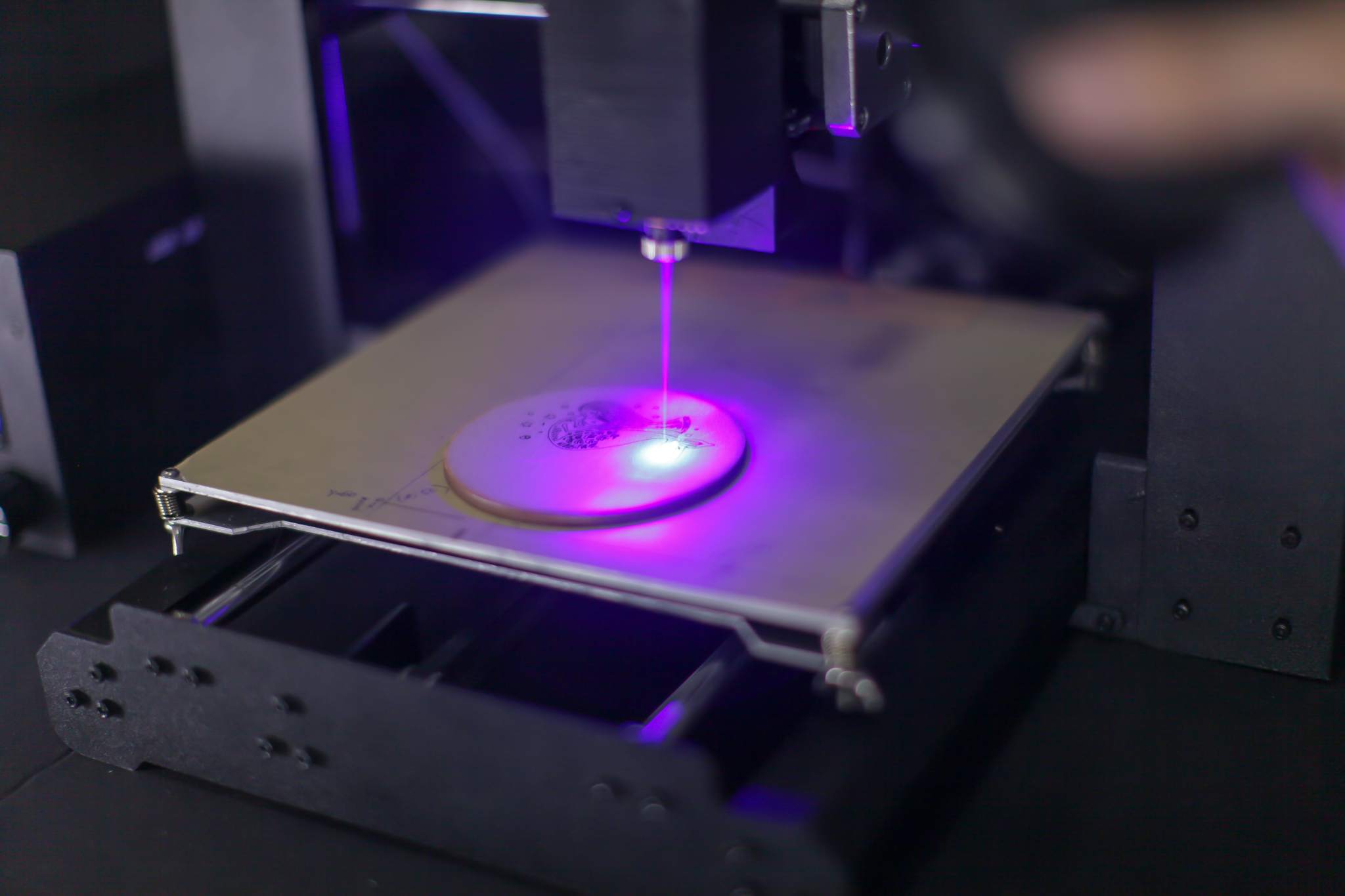

3D laser cutter printers operate on the principle of laser ablation, where a focused laser beam is directed onto a material, causing it to vaporize or burn away. The laser beam is controlled by a computer-aided design (CAD) software, which guides the laser along a predefined path. The precision and accuracy of the laser beam allow for intricate designs and detailed cuts.

H3: Types of Laser Cutter Printers

There are two main types of laser cutter printers:

- CO2 Laser Cutters: These are the most common type and use carbon dioxide gas to generate the laser beam. They excel in cutting and engraving non-metals such as wood, acrylic, and fabric.

- Fiber Laser Cutters: These use a fiber optic cable to deliver the laser beam. They are more powerful and can cut through metals, ceramics, and other hard materials with high precision.

H2: Applications of 3D Laser Cutter Printers

3D laser cutter printers have a wide range of applications in various industries and hobbies:

- Snapmaker Laser Cutting Guide Snapmaker Laser Cutting Guide: A Comprehensive Walkthrough

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide

- 3d Cutting Design 3D Cutting Design: Unleashing Precision And Creativity In Manufacturing

- Afinia Emblaser 2 Afinia Emblaser 2: A Comprehensive Guide To Laser Engraving And Cutting

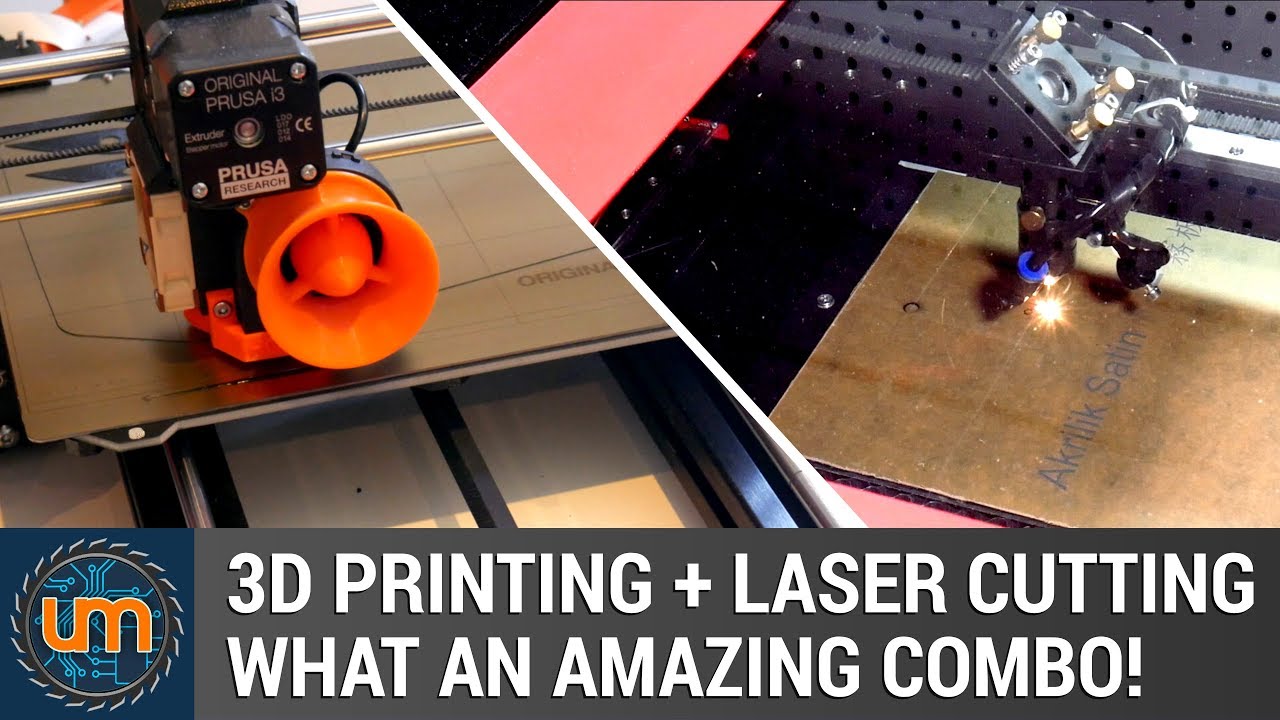

- 3d Printers And Laser Cutters 3D Printers And Laser Cutters: A Comprehensive Guide

- Manufacturing: Prototyping, batch production, and customization of parts

- Sign Making: Creating signs, logos, and displays

- Jewelry Making: Engraving and cutting jewelry pieces

- Craft Projects: Creating custom home décor, gifts, and accessories

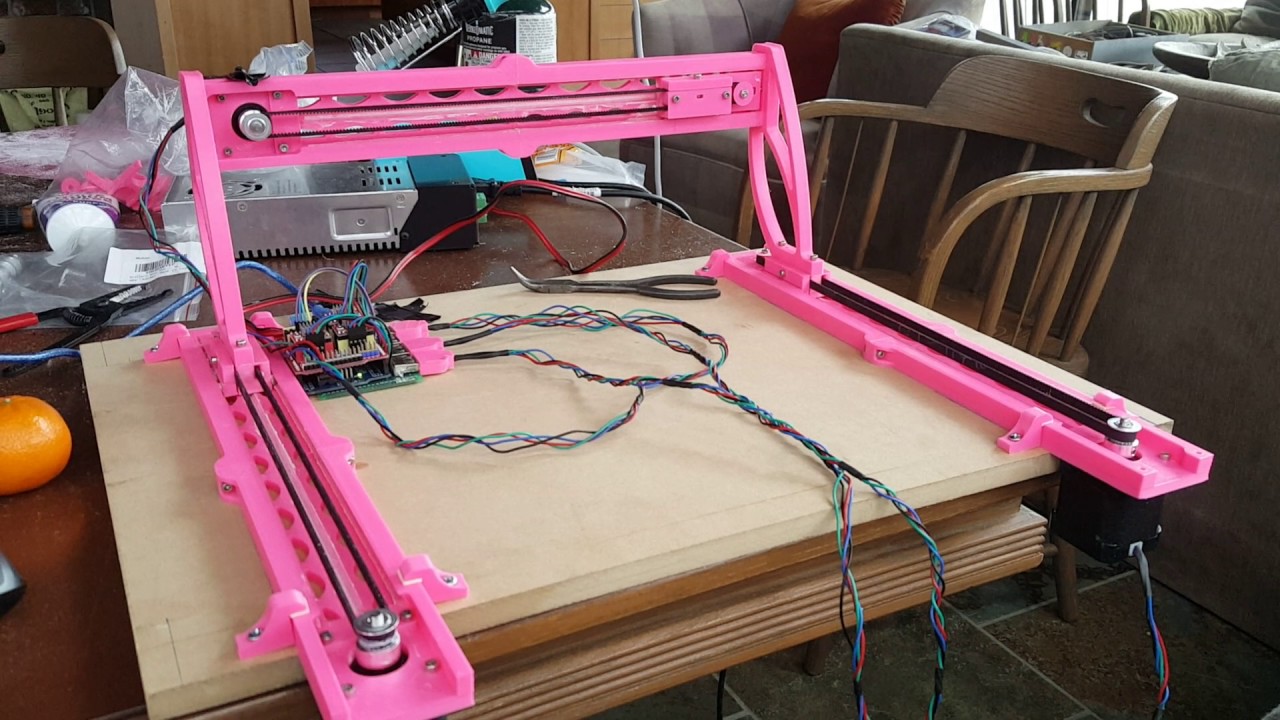

- DIY Projects: Personalizing electronics, building models, and more

3D laser cutter printers, also known as laser engravers or laser cutters, are revolutionizing the world of manufacturing, prototyping, and hobbyist projects. By harnessing the power of laser technology, these machines enable precise cutting, engraving, and marking on a wide range of materials, including wood, acrylic, metal, and leather. This guide delves into the intricacies of 3D laser cutter printers, exploring their capabilities, applications, and key considerations for choosing the right model.

H1: Understanding 3D Laser Cutter Printers

H2: How Laser Cutter Printers Work

3D laser cutter printers operate on the principle of laser ablation, where a focused laser beam is directed onto a material, causing it to vaporize or burn away. The laser beam is controlled by a computer-aided design (CAD) software, which guides the laser along a predefined path. The precision and accuracy of the laser beam allow for intricate designs and detailed cuts.

H3: Types of Laser Cutter Printers

There are two main types of laser cutter printers:

H1: Choosing the Right 3D Laser Cutter Printer

H2: Key Considerations

When selecting a 3D laser cutter printer, consider the following factors:

- Cutting Area: Determine the maximum size of materials you need to cut.

- Laser Power: The power of the laser determines the thickness and hardness of materials that can be cut.

- Material Compatibility: Ensure the printer is compatible with the materials you intend to work with.

- Software: Choose a printer with user-friendly software that allows for easy design and operation.

- Safety Features: Look for features such as enclosed workspaces, fume extraction systems, and emergency stop buttons.

H2: Recommended Models

Some recommended 3D laser cutter printer models include:

- Glowforge Pro: A user-friendly option with a large cutting area and high-quality results.

- XTool D1 Pro: A powerful fiber laser cutter capable of cutting metals and other hard materials.

- OMTech K40 Laser Engraver: A budget-friendly CO2 laser cutter suitable for hobbyists and small businesses.

H1: Conclusion

3D laser cutter printers offer a versatile and powerful tool for fabrication and design. By understanding how they work, their applications, and the key considerations for choosing the right model, you can harness the capabilities of this technology to create innovative and precise products.

FAQs

Q: What materials can 3D laser cutter printers cut?

A: CO2 laser cutters can cut non-metals like wood, acrylic, and fabric. Fiber laser cutters can cut metals, ceramics, and other hard materials.

Q: How thick can 3D laser cutter printers cut?

A: The cutting thickness depends on the laser power and material type. Generally, CO2 laser cutters can cut up to 1/2 inch of wood, while fiber laser cutters can cut up to 1/4 inch of metal.

Q: Are 3D laser cutter printers safe to use?

A: Yes, when used properly. They typically have enclosed workspaces, fume extraction systems, and emergency stop buttons to ensure safety.