3D Axis Laser Cutting: A Comprehensive Guide

Introduction

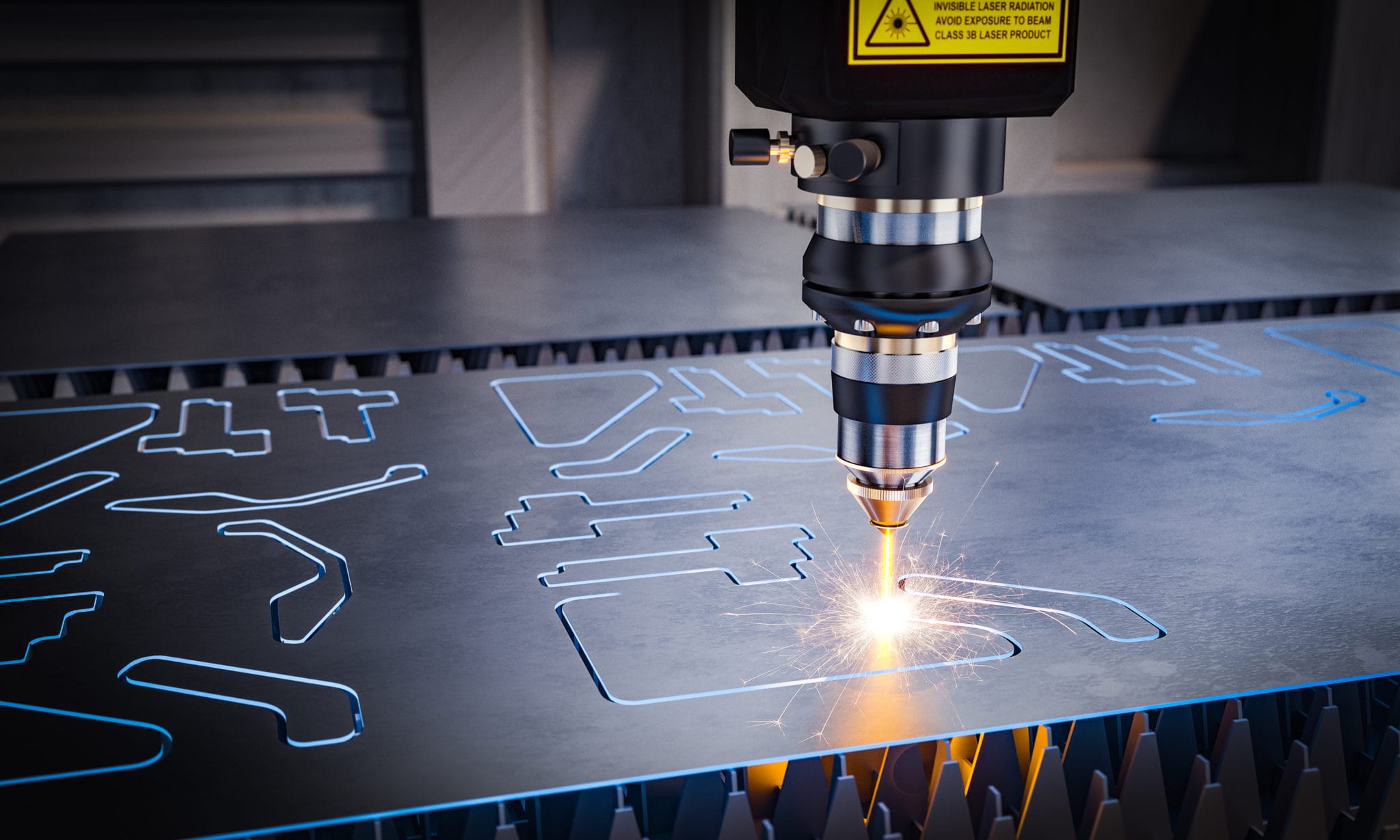

3D axis laser cutting is a revolutionary technology that has transformed the manufacturing industry. It offers unparalleled precision, speed, and flexibility, enabling businesses to produce complex and intricate parts with ease. This article provides a comprehensive overview of 3D axis laser cutting, exploring its principles, applications, and benefits.

Table of Content

H1: Principles of 3D Axis Laser Cutting

H2: Laser Source

The laser source generates the highly concentrated beam of light used for cutting. Common laser sources include:

- CO2 lasers: Produce a continuous beam with high power and efficiency.

- Fiber lasers: Offer high beam quality, low maintenance, and excellent cutting speeds.

- Nd:YAG lasers: Provide high power and are suitable for cutting reflective materials.

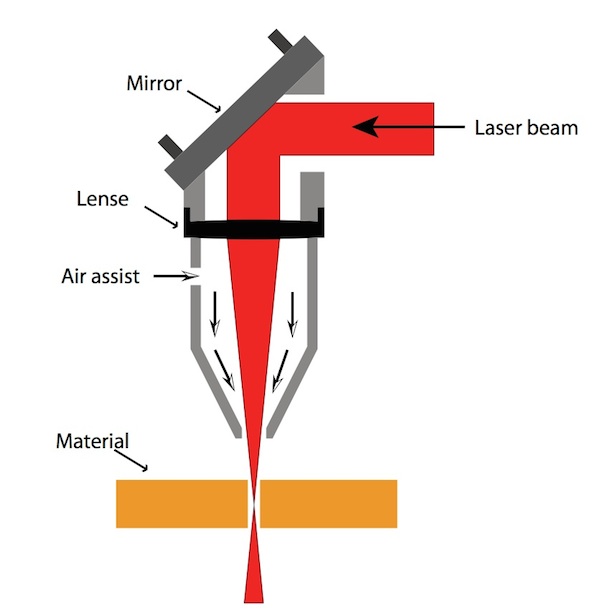

H3: Laser Beam Delivery System

The laser beam delivery system directs the laser beam from the source to the cutting head. It consists of:

- 3d Laser Cut Files Free 3D Laser Cut Files Free: Unleash Your Creativity

- 3d Printers And Laser Cutters 3D Printers And Laser Cutters: A Comprehensive Guide

- Laser Cutting Ender 3 Laser Cutting Ender 3: A Comprehensive Guide To Enhancing Your 3D Printer’s Capabilities

- 3d Laser Cut Animal 3D Laser Cut Animal: A Comprehensive Guide To Laser Cutting Animal Designs

- 3d Laser Cutting Design 3D Laser Cutting Design: Revolutionizing Manufacturing And Creativity

- Mirrors: Reflect the laser beam along the desired path.

- Lenses: Focus the laser beam to a small spot size for precise cutting.

- Fiber optic cables: Transmit the laser beam over long distances.

- Nozzle: Delivers a gas (e.g., oxygen or nitrogen) to assist with cutting.

- Focusing optics: Focus the laser beam to the desired spot size.

- Height control system: Maintains the correct distance between the laser beam and the material surface.

- Cutting of complex body parts, such as fenders, hoods, and door panels.

- Fabrication of precision components for engines and transmissions.

- Production of lightweight and durable aircraft parts.

- Cutting of intricate honeycomb structures for aircraft wings.

- Fabrication of surgical instruments and implants.

- Cutting of stents and other medical devices.

- Cutting of printed circuit boards (PCBs).

- Production of precision electronic components.

- The laser beam’s precise focusing allows for extremely accurate and intricate cuts.

- Computer-controlled systems ensure consistent and repeatable results.

- The high power and speed of the laser beam enable fast and efficient cutting.

- Automated systems minimize setup time and reduce labor costs.

- 3D axis laser cutting can process a wide range of materials, including metals, plastics, and composites.

- It can create complex shapes and contours that are difficult or impossible with other cutting methods.

- The focused laser beam minimizes material waste, resulting in reduced production costs.

- Precise cuts eliminate the need for extensive post-processing.

3D axis laser cutting is a revolutionary technology that has transformed the manufacturing industry. It offers unparalleled precision, speed, and flexibility, enabling businesses to produce complex and intricate parts with ease. This article provides a comprehensive overview of 3D axis laser cutting, exploring its principles, applications, and benefits.

H1: Principles of 3D Axis Laser Cutting

3D axis laser cutting utilizes a focused beam of laser energy to cut through materials with precision. The laser beam is guided by a computer-controlled system, allowing it to move in three axes (X, Y, and Z) to create intricate shapes and contours.

H2: Laser Source

The laser source generates the highly concentrated beam of light used for cutting. Common laser sources include:

H4: Cutting Head

The cutting head is responsible for directing the laser beam onto the material surface. It includes:

H1: Applications of 3D Axis Laser Cutting

3D axis laser cutting finds widespread applications in various industries, including:

H2: Automotive Industry

H3: Aerospace Industry

H4: Medical Industry

H5: Electronics Industry

H1: Benefits of 3D Axis Laser Cutting

3D axis laser cutting offers numerous benefits over traditional cutting methods:

H2: Precision and Accuracy

H3: Speed and Efficiency

H4: Flexibility and Versatility

H5: Minimal Material Waste

H1: Conclusion

3D axis laser cutting is a cutting-edge technology that has revolutionized the manufacturing industry. Its precision, speed, flexibility, and cost-effectiveness make it an ideal choice for a wide range of applications. As technology continues to advance, we can expect even greater capabilities and benefits from this innovative cutting method.

FAQs

Q: What materials can be cut with 3D axis laser cutting?

A: A wide range of materials, including metals (e.g., steel, aluminum, titanium), plastics (e.g., acrylic, polycarbonate), and composites (e.g., carbon fiber, fiberglass).

Q: What is the maximum cutting thickness for 3D axis laser cutting?

A: Cutting thickness depends on the material and laser source. Typically, CO2 lasers can cut up to 25 mm of steel, while fiber lasers can cut up to 100 mm.

Q: What is the accuracy of 3D axis laser cutting?

A: Accuracies can reach up to ±0.005 mm, depending on the machine and material being cut.

Q: What are the safety considerations for 3D axis laser cutting?

A: Proper precautions must be taken, including wearing protective eyewear, using fume extraction systems, and following safe operating procedures.