3D and Laser Cutting: A Comprehensive Guide to Advanced Manufacturing Techniques

Introduction

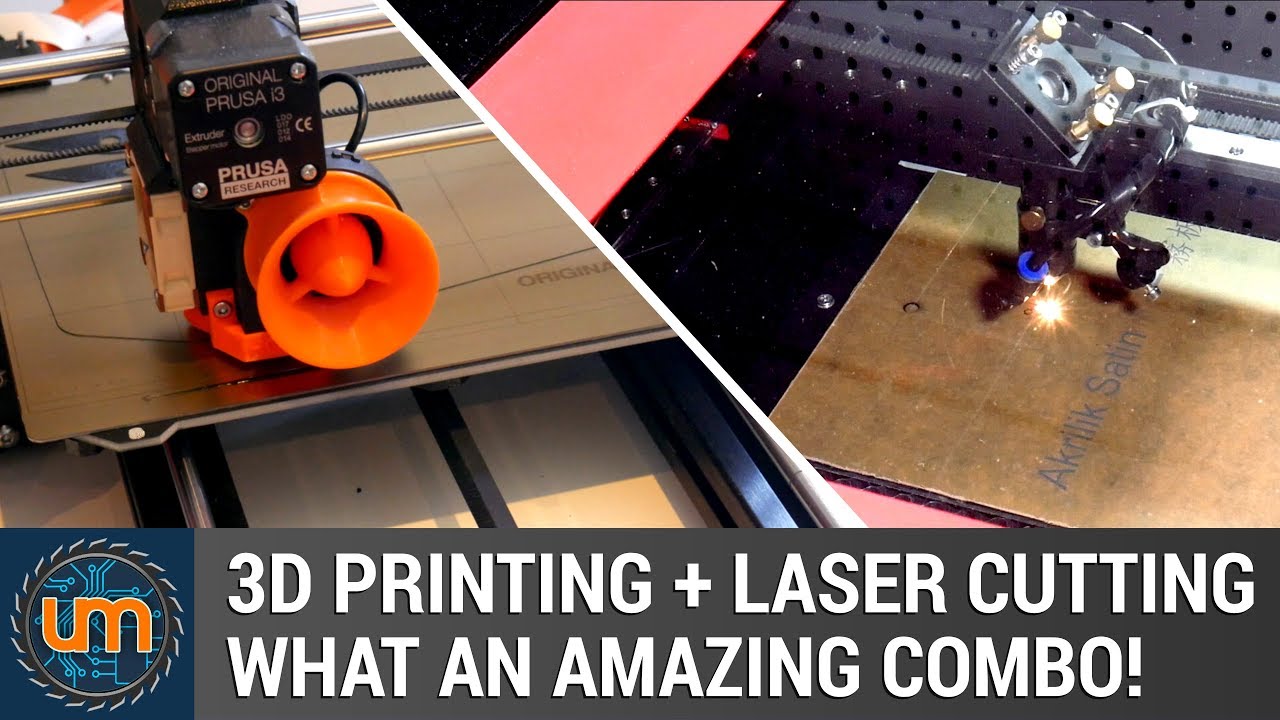

In the realm of modern manufacturing, 3D printing and laser cutting have emerged as transformative technologies that revolutionize product design, prototyping, and production. These cutting-edge techniques offer unparalleled precision, flexibility, and efficiency, enabling businesses to create innovative products and optimize their manufacturing processes. This comprehensive guide will delve into the intricate details of 3D printing and laser cutting, exploring their applications, advantages, and considerations.

Table of Content

- 1 3D and Laser Cutting: A Comprehensive Guide to Advanced Manufacturing Techniques

- 1.1 Introduction

- 1.2 Chapter 1: 3D Printing: Unveiling the World of Additive Manufacturing

- 1.2.1 H2.2 Types of 3D Printing Technologies

- 1.2.2 H2.3 Advantages of 3D Printing

- 1.3 Chapter 1: 3D Printing: Unveiling the World of Additive Manufacturing

- 1.3.3 H2.1 What is 3D Printing?

- 1.3.4 H2.2 Types of 3D Printing Technologies

- 1.4 Chapter 2: Laser Cutting: Precision and Versatility in Fabrication

- 1.4.5 H2.1 What is Laser Cutting?

- 1.4.6 H2.2 Types of Laser Cutting Systems

- 1.4.7 H2.3 Advantages of Laser Cutting

- 1.5 Chapter 3: Applications of 3D Printing and Laser Cutting

- 1.5.8 H3.1 3D Printing Applications

- 1.5.9 H3.2 Laser Cutting Applications

- 1.6 Chapter 4: Considerations for 3D Printing and Laser Cutting

- 1.6.10 H4.1 Material Selection

- 1.6.11 H4.2 Design for Manufacturing

- 1.6.12 H4.3 Post-Processing

- 1.7 Chapter 5: Conclusion

- 1.8 FAQs

Chapter 1: 3D Printing: Unveiling the World of Additive Manufacturing

3D printing, also known as additive manufacturing, is a revolutionary process that creates three-dimensional objects from digital models. Unlike traditional manufacturing methods that involve subtractive processes like milling or cutting, 3D printing builds objects layer by layer, adding material as it goes.

H2.2 Types of 3D Printing Technologies

Various 3D printing technologies exist, each with its own unique characteristics and applications:

- Fused Deposition Modeling (FDM): FDM is a widely used method that extrudes molten plastic material through a heated nozzle to create objects.

- Stereolithography (SLA): SLA uses a laser to cure liquid resin layer by layer, creating high-resolution and detailed parts.

- Selective Laser Sintering (SLS): SLS fuses powdered material using a laser, producing strong and durable parts suitable for functional applications.

H2.3 Advantages of 3D Printing

- Snapmaker Laser Cutting Guide Snapmaker Laser Cutting Guide: A Comprehensive Walkthrough

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide To Precision Fabrication

- 3d Cutting Design 3D Cutting Design: Unleashing Precision And Creativity In Manufacturing

- 3 D Laser Cutting 3D Laser Cutting: A Revolutionary Technology For Precision Manufacturing

- 3d Laser Cut Template 3D Laser Cut Template: A Comprehensive Guide

- Rapid Prototyping: 3D printing enables rapid prototyping, allowing designers to quickly create physical models for testing and evaluation.

- Design Freedom: 3D printing offers unparalleled design freedom, enabling the creation of complex and intricate geometries that are difficult or impossible to produce using traditional methods.

- Customization: 3D printing empowers businesses to create customized products tailored to specific customer needs.

- Cost-Effectiveness: For small-scale production runs and prototyping, 3D printing can be cost-effective compared to traditional manufacturing.

In the realm of modern manufacturing, 3D printing and laser cutting have emerged as transformative technologies that revolutionize product design, prototyping, and production. These cutting-edge techniques offer unparalleled precision, flexibility, and efficiency, enabling businesses to create innovative products and optimize their manufacturing processes. This comprehensive guide will delve into the intricate details of 3D printing and laser cutting, exploring their applications, advantages, and considerations.

Chapter 1: 3D Printing: Unveiling the World of Additive Manufacturing

H2.1 What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary process that creates three-dimensional objects from digital models. Unlike traditional manufacturing methods that involve subtractive processes like milling or cutting, 3D printing builds objects layer by layer, adding material as it goes.

H2.2 Types of 3D Printing Technologies

Various 3D printing technologies exist, each with its own unique characteristics and applications:

Chapter 2: Laser Cutting: Precision and Versatility in Fabrication

H2.1 What is Laser Cutting?

Laser cutting is a process that utilizes a highly focused laser beam to cut or engrave materials. The laser’s intense heat vaporizes or melts the material, creating precise and clean cuts.

H2.2 Types of Laser Cutting Systems

Laser cutting systems vary depending on the type of laser used:

- CO2 Lasers: CO2 lasers are commonly used for cutting non-metallic materials such as acrylic, wood, and fabrics.

- Fiber Lasers: Fiber lasers are more powerful and efficient, suitable for cutting metals and thicker materials.

- YAG Lasers: YAG lasers are versatile and can cut a wide range of materials, including metals, ceramics, and plastics.

H2.3 Advantages of Laser Cutting

- Precision and Accuracy: Laser cutting delivers exceptional precision and accuracy, producing clean and burr-free cuts.

- Versatility: Laser cutting can process a wide range of materials, including metals, plastics, wood, and fabrics.

- Speed and Efficiency: Laser cutting is a fast and efficient process, reducing production time and costs.

- Non-Contact Process: Laser cutting is a non-contact process, eliminating the need for physical tools and reducing wear and tear on equipment.

Chapter 3: Applications of 3D Printing and Laser Cutting

H3.1 3D Printing Applications

- Prototyping: Rapid prototyping of functional and aesthetic components.

- Manufacturing: Production of end-use parts in small batches or for custom applications.

- Medical: Fabrication of medical devices, prosthetics, and implants.

- Architecture: Creation of architectural models and scale prototypes.

- Education: Hands-on learning and prototyping for students and researchers.

H3.2 Laser Cutting Applications

- Metal Fabrication: Cutting and engraving of metal parts for automotive, aerospace, and industrial applications.

- Electronics: Precision cutting of circuit boards and electronic components.

- Textile and Apparel: Cutting and engraving of fabrics, leather, and other textile materials.

- Packaging: Creation of custom packaging and displays.

- Signage and Display: Production of signs, banners, and other display materials.

Chapter 4: Considerations for 3D Printing and Laser Cutting

H4.1 Material Selection

The choice of materials for 3D printing and laser cutting is crucial and depends on the desired properties and application. Consider factors such as strength, durability, flexibility, and thermal resistance.

H4.2 Design for Manufacturing

To optimize the manufacturing process, it is essential to consider design for manufacturing (DFM) principles. This involves designing parts with appropriate tolerances, clearances, and features that facilitate efficient production.

H4.3 Post-Processing

3D printed and laser-cut parts may require post-processing steps to enhance their appearance or functionality. These steps may include sanding, smoothing, painting, or heat treatment.

Chapter 5: Conclusion

3D printing and laser cutting have revolutionized the manufacturing landscape, enabling businesses to create innovative products and optimize their production processes. These cutting-edge technologies offer unparalleled precision, flexibility, and efficiency, empowering businesses to meet the demands of the modern market. By understanding the principles, advantages, and considerations of 3D printing and laser cutting, businesses can leverage these technologies to gain a competitive edge and drive innovation.

FAQs

Q: What is the difference between 3D printing and laser cutting?

A: 3D printing is an additive manufacturing process that builds objects layer by layer, while laser cutting is a subtractive process that uses a laser beam to cut or engrave materials.

Q: What are the most common materials used in 3D printing?

A: The most common materials used in 3D printing are plastics (PLA, ABS, PETG), metals (stainless steel, titanium), and ceramics.

Q: What are the advantages of laser cutting over traditional cutting methods?

A: Laser cutting offers higher precision, cleaner cuts, faster processing times, and the ability to cut a wider range of materials.

Q: How can I learn more about 3D printing and laser cutting?

A: There are numerous online resources, workshops, and training programs available to provide more in-depth knowledge about 3D printing and laser cutting.