H1: Unleashing the Power of DXF 3D Laser Cutting: A Comprehensive Guide

H2: Introduction to DXF 3D Laser Cutting

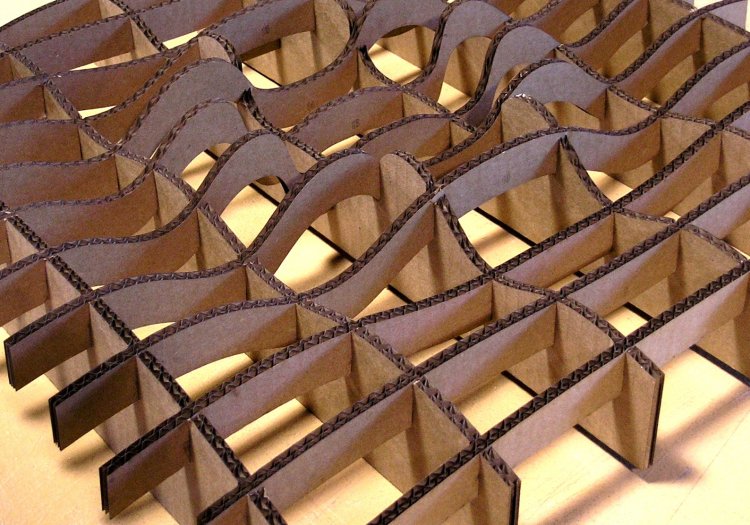

DXF (Drawing Exchange Format) 3D laser cutting is a cutting-edge technology that empowers manufacturers to create intricate and complex 3D objects from various materials. This process involves using a laser to precisely cut materials based on 3D CAD models stored in DXF files.

Table of Content

- 1 H1: Unleashing the Power of DXF 3D Laser Cutting: A Comprehensive Guide

- 1.1 H2: Introduction to DXF 3D Laser Cutting

- 1.2 H3: Advantages of DXF 3D Laser Cutting

- 1.3 H3: Applications of DXF 3D Laser Cutting

- 1.4 H3: Advantages of DXF 3D Laser Cutting

- 1.5 H2: Process of DXF 3D Laser Cutting

- 1.6 H2: Choosing the Right DXF 3D Laser Cutting Service

- 1.7 H2: Conclusion

- 1.8 FAQs

H3: Advantages of DXF 3D Laser Cutting

H3: Applications of DXF 3D Laser Cutting

DXF 3D laser cutting finds applications in numerous industries, including:

- Automotive: Manufacturing of interior and exterior components, such as dashboards and body panels.

- 3d Puzzle Laser Cut Dxf 3D Puzzle Laser Cut DXF: A Comprehensive Guide For Crafters And Hobbyists

- 3 D Laser Cutting 3D Laser Cutting: A Revolutionary Technology For Precision Manufacturing

- 3d Laser Carving 3D Laser Carving: A Revolutionary Technique For Intricate Designs

- 3d Laser Cut Cat 3D Laser Cut Cat: A Unique And Personalized Home Decor

- Shapeways Laser Cutting Shapeways Laser Cutting: A Comprehensive Guide To Advanced Manufacturing

- Precision and Accuracy: DXF 3D laser cutting ensures exceptional precision and accuracy, allowing for the creation of highly detailed and intricate objects.

- Material Versatility: This technology can cut a wide range of materials, including metals, plastics, wood, and composites, providing flexibility in design and manufacturing.

- Cost-Effectiveness: DXF 3D laser cutting offers cost-effective solutions compared to traditional cutting methods, reducing material waste and production time.

- Aerospace: Creation of lightweight and durable aircraft components, such as wings and fuselage panels.

- Medical: Production of medical devices, surgical instruments, and prosthetics.

- Consumer Electronics: Fabrication of electronic components, such as mobile phone cases and laptop housings.

- Art and Design: Creation of decorative objects, sculptures, and architectural elements.

- Expertise and Experience: Choose a company with proven experience in DXF 3D laser cutting and a track record of delivering high-quality products.

- Equipment Capabilities: Ensure that the service provider has advanced laser cutting equipment capable of handling your specific material and design requirements.

- Design Support: Look for companies that offer design support to assist with optimizing your 3D models for laser cutting.

- Quality Control: Choose a service that adheres to strict quality control measures to guarantee the accuracy and precision of your products.

- Customer Service: Select a provider with excellent customer service to ensure timely responses to your queries and support throughout the project.

DXF (Drawing Exchange Format) 3D laser cutting is a cutting-edge technology that empowers manufacturers to create intricate and complex 3D objects from various materials. This process involves using a laser to precisely cut materials based on 3D CAD models stored in DXF files.

H3: Advantages of DXF 3D Laser Cutting

H2: Process of DXF 3D Laser Cutting

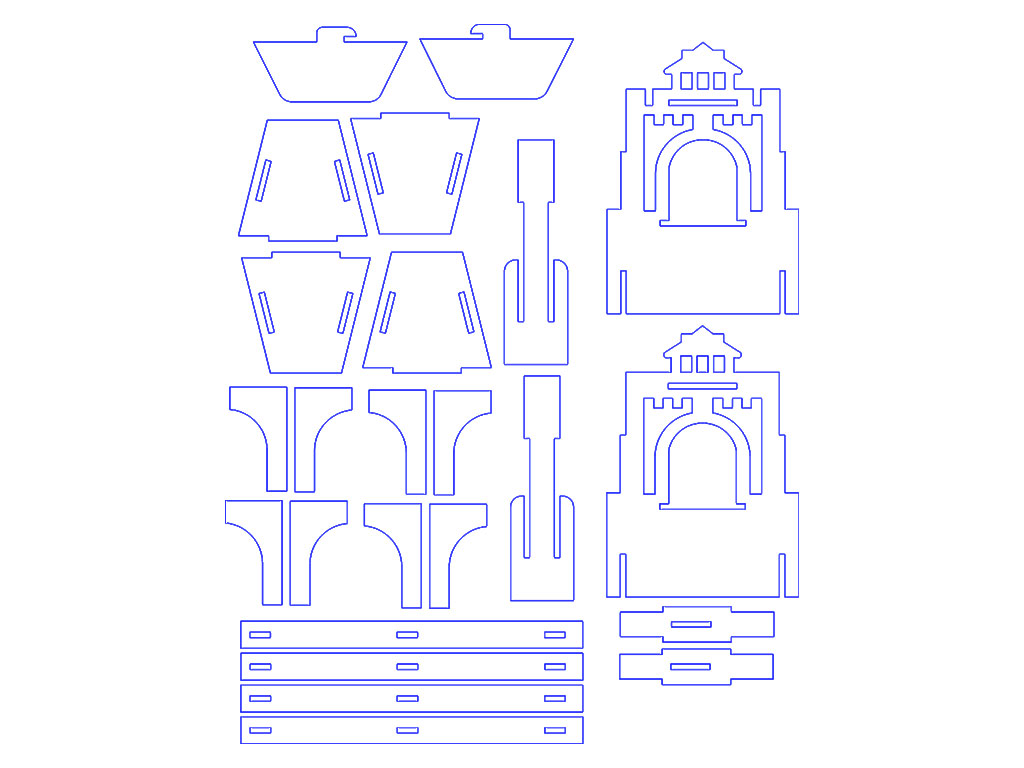

Step 1: Design and Modeling

Create a 3D CAD model using software compatible with DXF format. The model should accurately represent the desired object.

Step 2: File Conversion

Export the 3D CAD model as a DXF file. This file contains the geometrical data of the object.

Step 3: Laser Cutting

Load the DXF file into the laser cutting machine. The laser will follow the path defined in the DXF file, cutting the material precisely.

Step 4: Post-Processing

After cutting, the object may require additional post-processing, such as deburring, sanding, or assembly, to achieve the desired finish.

H2: Choosing the Right DXF 3D Laser Cutting Service

When selecting a DXF 3D laser cutting service, consider the following factors:

H2: Conclusion

DXF 3D laser cutting technology revolutionizes manufacturing by enabling the creation of complex and intricate objects with exceptional precision and material versatility. By understanding the advantages, applications, process, and selection criteria, businesses can leverage this technology to achieve greater design flexibility, cost-effectiveness, and automation in their production processes.

FAQs

Q: What materials can be cut using DXF 3D laser cutting?

A: DXF 3D laser cutting can cut a wide range of materials, including metals, plastics, wood, and composites.

Q: What is the typical accuracy and precision of DXF 3D laser cutting?

A: DXF 3D laser cutting offers exceptional accuracy and precision, typically within a few thousandths of an inch.

Q: Is DXF 3D laser cutting suitable for high-volume production?

A: Yes, DXF 3D laser cutting is suitable for both low-volume and high-volume production, thanks to its automation capabilities and efficient material utilization.

Q: What are the cost considerations for DXF 3D laser cutting?

A: The cost of DXF 3D laser cutting varies depending on the material, complexity of the design, and volume of production. However, it generally offers cost-effective solutions compared to traditional cutting methods.

Q: How can I find a reputable DXF 3D laser cutting service?

A: Consider the factors discussed in the article, such as expertise, equipment capabilities, design support, quality control, and customer service. Research online reviews and request quotes from multiple providers to make an informed decision.