3D Fabric Laser Cutting: A Revolutionary Textile Innovation

Introduction

3D fabric laser cutting is a cutting-edge technology that has revolutionized the textile industry. This innovative process uses a laser beam to precisely cut and shape fabrics, creating intricate three-dimensional structures and designs. Unlike traditional cutting methods, 3D fabric laser cutting offers unparalleled precision, flexibility, and versatility, enabling designers and manufacturers to push the boundaries of textile innovation.

Table of Content

How Does 3D Fabric Laser Cutting Work?

Benefits of 3D Fabric Laser Cutting

- Precision and Accuracy: Laser cutting offers unmatched precision, ensuring precise cuts and sharp edges.

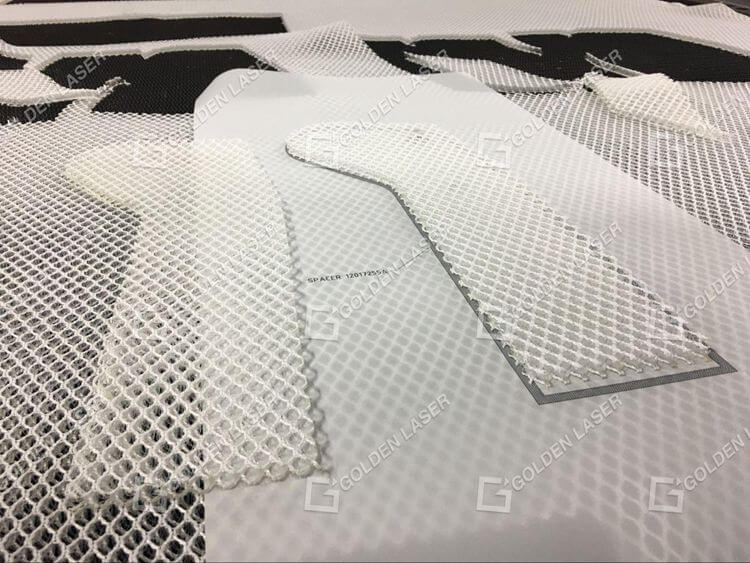

- Flexibility and Versatility: This technology can cut a wide range of fabrics, from delicate silks to heavy-duty canvas, enabling designers to create a diverse range of products.

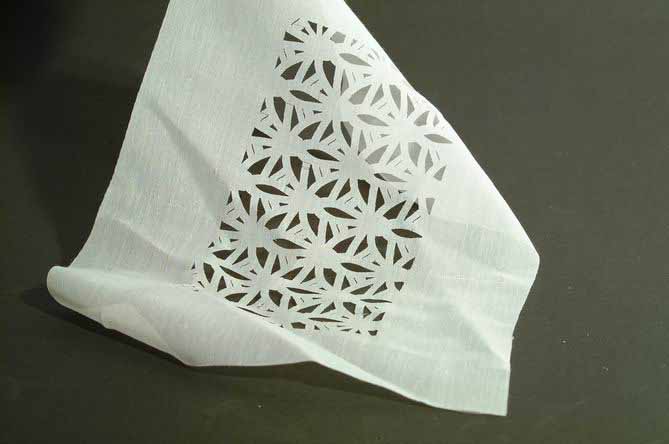

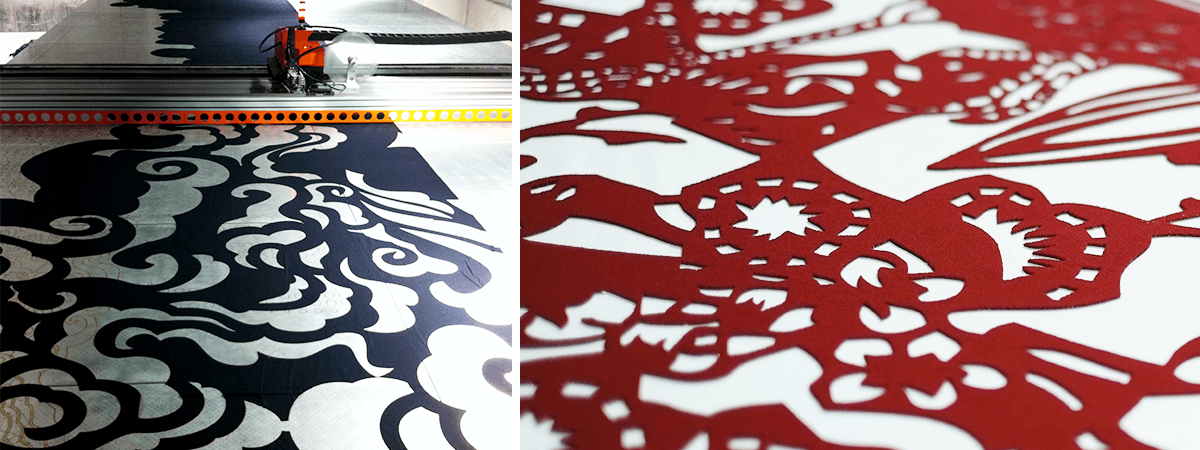

- Intricate Designs: 3D fabric laser cutting allows for the creation of highly intricate and complex designs that would be impossible to achieve with traditional cutting methods.

- Reduced Waste: Laser cutting minimizes fabric waste by precisely cutting the desired shapes, reducing material consumption and production costs.

- Increased Productivity: Automated laser cutting systems can operate continuously, increasing production efficiency and reducing lead times.

Applications of 3D Fabric Laser Cutting

3D fabric laser cutting has a wide range of applications across various industries, including:

3D fabric laser cutting is a cutting-edge technology that has revolutionized the textile industry. This innovative process uses a laser beam to precisely cut and shape fabrics, creating intricate three-dimensional structures and designs. Unlike traditional cutting methods, 3D fabric laser cutting offers unparalleled precision, flexibility, and versatility, enabling designers and manufacturers to push the boundaries of textile innovation.

- 3d Laser Cut Crystal Cubes 3D Laser Cut Crystal Cubes: The Ultimate Guide To Captivating Decor And Personalized Gifts

- Laser Cut Multilayer 3d Mandala Dxf File Laser Cut Multilayer 3D Mandala DXF File: Unleashing Intricate Beauty

- 3d Laser Cut Car 3D Laser Cut Car: A Comprehensive Guide To Precision And Customization

- 3d Laser Cut Box 3D Laser Cut Box: A Comprehensive Guide

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

How Does 3D Fabric Laser Cutting Work?

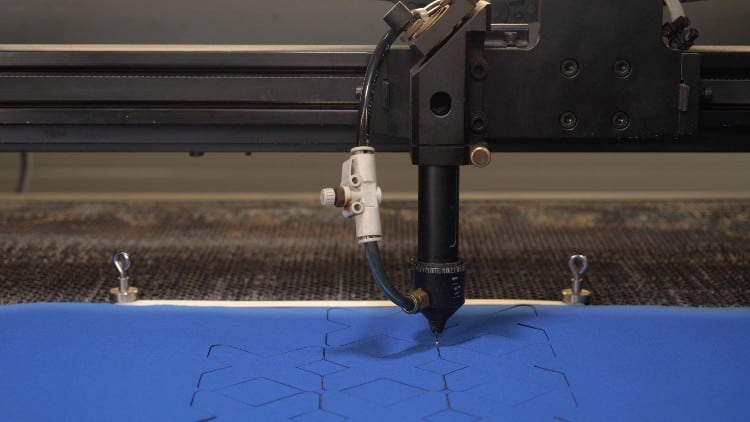

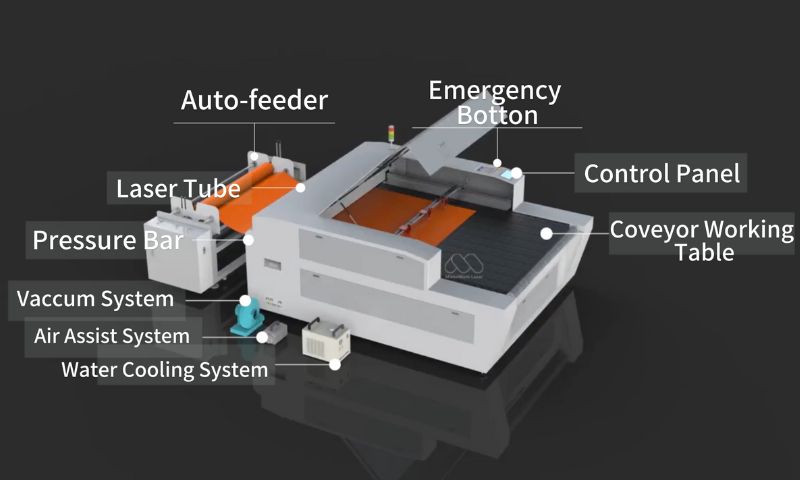

3D fabric laser cutting involves the use of a high-powered laser beam that is directed onto the fabric surface. The laser beam melts or vaporizes the fabric fibers, precisely cutting and shaping the material. The laser’s path is controlled by computer-aided design (CAD) software, allowing for complex and intricate designs to be created.

Benefits of 3D Fabric Laser Cutting

- Precision and Accuracy: Laser cutting offers unmatched precision, ensuring precise cuts and sharp edges.

- Fashion and Apparel: Creating unique and innovative clothing designs, accessories, and footwear.

- Home Furnishings: Producing customized curtains, upholstery, and other home décor items with intricate patterns and textures.

- Medical and Healthcare: Developing breathable materials for medical gowns, surgical masks, and wound dressings.

- Automotive: Creating lightweight and durable interior components, such as seat covers and headliners.

- Aerospace: Producing high-performance fabrics for aircraft interiors and protective gear.

- What types of fabrics can be cut with 3D laser cutting?

- How does 3D fabric laser cutting differ from traditional cutting methods?

- Is 3D fabric laser cutting expensive?

- What are the safety considerations for 3D fabric laser cutting?

Conclusion

3D fabric laser cutting is a transformative technology that empowers designers and manufacturers to unleash their creativity and push the boundaries of textile innovation. Its unparalleled precision, flexibility, and versatility enable the creation of intricate and functional fabrics that meet the demands of various industries. As technology continues to evolve, 3D fabric laser cutting will continue to play a pivotal role in shaping the future of textile design and production.

FAQs

A wide range of fabrics can be cut with 3D laser cutting, including natural fibers (e.g., cotton, linen), synthetic fibers (e.g., polyester, nylon), and blends.

Traditional cutting methods, such as manual cutting or die cutting, are less precise and versatile than 3D fabric laser cutting. Laser cutting offers cleaner cuts, sharper edges, and the ability to create intricate designs.

The cost of 3D fabric laser cutting varies depending on the complexity of the design, the type of fabric, and the volume of production. However, it can be cost-effective for small-scale production and prototyping.

Laser cutting involves the use of high-powered lasers, so it is essential to adhere to safety precautions, such as wearing appropriate protective gear and operating the equipment in a well-ventilated area.