Laser Cut 3D Model Files: A Comprehensive Guide

Introduction

Laser cutting technology has revolutionized the fabrication industry, enabling the precise and efficient creation of complex 3D models from various materials. Laser cut 3D model files serve as digital blueprints, guiding laser cutters to cut and shape materials with unmatched accuracy and detail. This article delves into the world of laser cut 3D model files, exploring their applications, benefits, creation process, and best practices.

Table of Content

- 1 Laser Cut 3D Model Files: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Applications of Laser Cut 3D Model Files

- 1.3 Benefits of Laser Cut 3D Model Files

- 1.4 Applications of Laser Cut 3D Model Files

- 1.5 Creating Laser Cut 3D Model Files

- 1.6 Best Practices for Laser Cut 3D Model Files

- 1.7 Conclusion

- 1.8 FAQs

Applications of Laser Cut 3D Model Files

- Architecture and Design: Creating architectural models, scale prototypes, and custom interior design elements

- Industrial Manufacturing: Producing prototypes, custom components, and functional parts for various industries

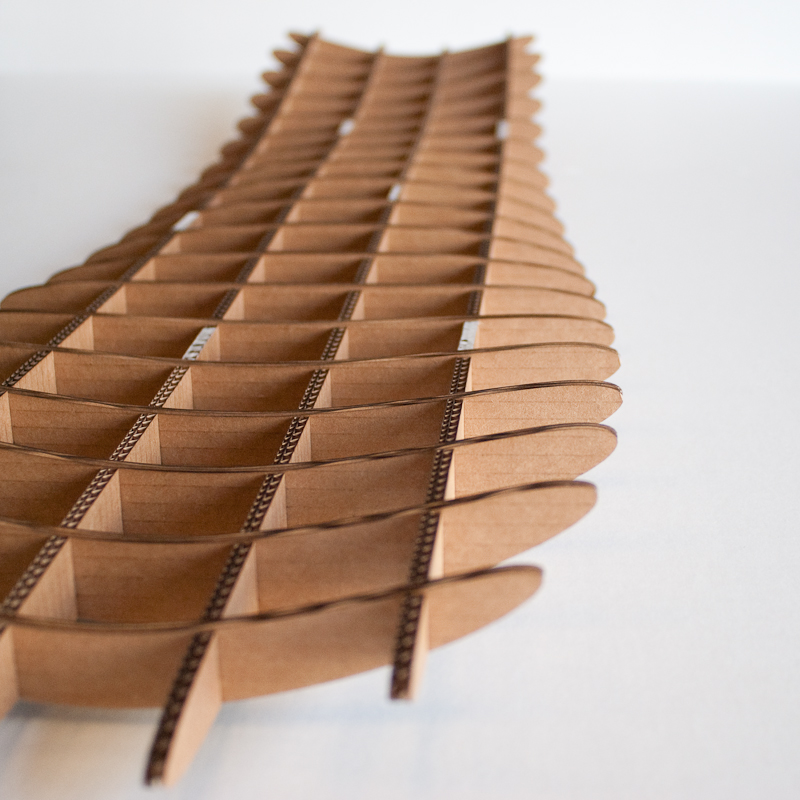

- Art and Craft: Making unique decorative pieces, sculptures, and personalized gifts

- Education: Facilitating hands-on learning through the creation of educational models and interactive displays

Benefits of Laser Cut 3D Model Files

- Precision: Laser cutting ensures precise cuts with minimal distortion, allowing for the creation of intricate and accurate models.

- Efficiency: The automated process of laser cutting significantly reduces production time compared to traditional methods.

- 3d Laser Cut Art 3D Laser Cut Art: Unlocking A World Of Dimensional Creativity

- Laser Cut 3d Angel Laser Cut 3D Angel: A Celestial Masterpiece For Home Decor And Gift Giving

- Laser Cut 3d Dragon Laser Cut 3D Dragon: A Detailed Guide To Crafting A Majestic Masterpiece

- Anycubic Mega Pro Laser Cutting Anycubic Mega Pro: A Comprehensive Guide To Laser Cutting Precision

- 3d Laser Cut Model 3D Laser Cut Models: A Comprehensive Guide

- Architecture and Design: Creating architectural models, scale prototypes, and custom interior design elements

- Industrial Manufacturing: Producing prototypes, custom components, and functional parts for various industries

- Versatility: Laser cutting can handle a wide range of materials, including wood, metal, acrylic, and leather, providing flexibility in design.

- Cost-effectiveness: Laser cutting can be more cost-effective than traditional manufacturing methods for small-scale production runs.

- Customization: 3D model files allow for easy customization, enabling the creation of unique and personalized models.

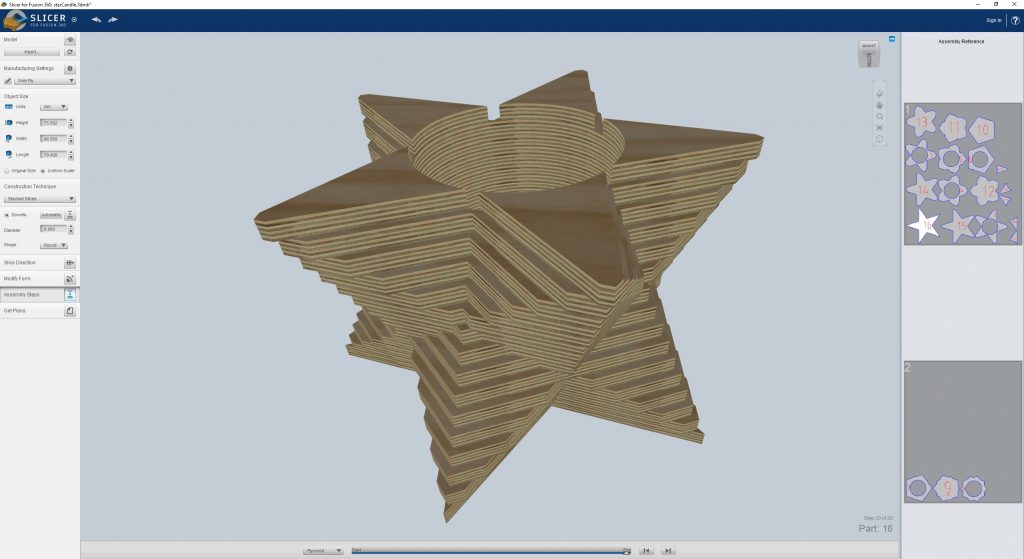

- Design Software: 3D modeling software such as AutoCAD, SolidWorks, or Blender is used to create the digital models.

- File Format: STL (Stereolithography) is the most common file format for laser cutting, as it describes the model’s surface geometry.

- Material Considerations: The choice of material depends on the intended application and the laser cutter’s capabilities.

- Cutting Parameters: Laser cutters require specific settings for each material, including laser power, speed, and focus.

- Optimize for Laser Cutting: Design models with clean lines, avoiding complex curves or sharp angles that can be difficult to cut.

- Consider Material Thickness: Ensure that the model’s thickness is compatible with the laser cutter’s capabilities.

- Test Cutting: Perform test cuts to determine optimal cutting parameters and ensure accurate results.

- Clean Cut Edges: Post-process the cut models to remove any burrs or sharp edges for safety and aesthetic purposes.

-

What software is used to create laser cut 3D model files?

- AutoCAD, SolidWorks, and Blender are popular 3D modeling software options.

-

What is the most common file format for laser cutting?

- STL (Stereolithography) is the standard file format for laser cutting.

-

What materials can be laser cut?

- Laser cutters can handle a wide range of materials, including wood, metal, acrylic, and leather.

-

How can I optimize my 3D model files for laser cutting?

- Design with clean lines, consider material thickness, and perform test cuts to ensure accuracy.

-

What are the benefits of using laser cut 3D model files?

- Precision, efficiency, versatility, cost-effectiveness, and customization.

Laser cutting technology has revolutionized the fabrication industry, enabling the precise and efficient creation of complex 3D models from various materials. Laser cut 3D model files serve as digital blueprints, guiding laser cutters to cut and shape materials with unmatched accuracy and detail. This article delves into the world of laser cut 3D model files, exploring their applications, benefits, creation process, and best practices.

Applications of Laser Cut 3D Model Files

Laser cut 3D model files find applications in a wide range of industries, including:

Creating Laser Cut 3D Model Files

Best Practices for Laser Cut 3D Model Files

Conclusion

Laser cut 3D model files are essential for leveraging the precision and efficiency of laser cutting technology. By understanding their applications, benefits, creation process, and best practices, designers and manufacturers can unlock the full potential of laser cutting for a wide range of projects.

FAQs