3D Layered Laser Cut: Revolutionizing Manufacturing and Design

Introduction:

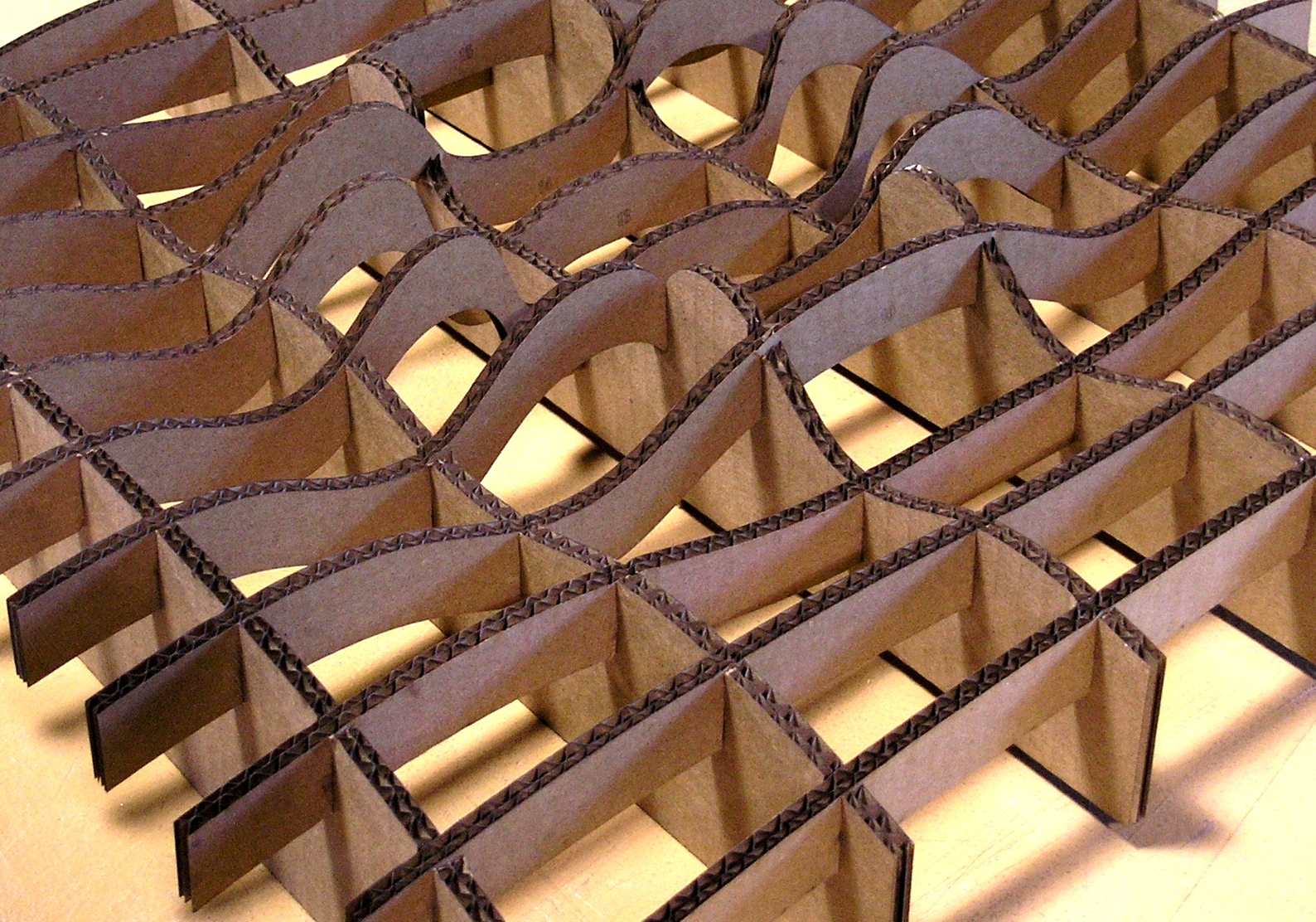

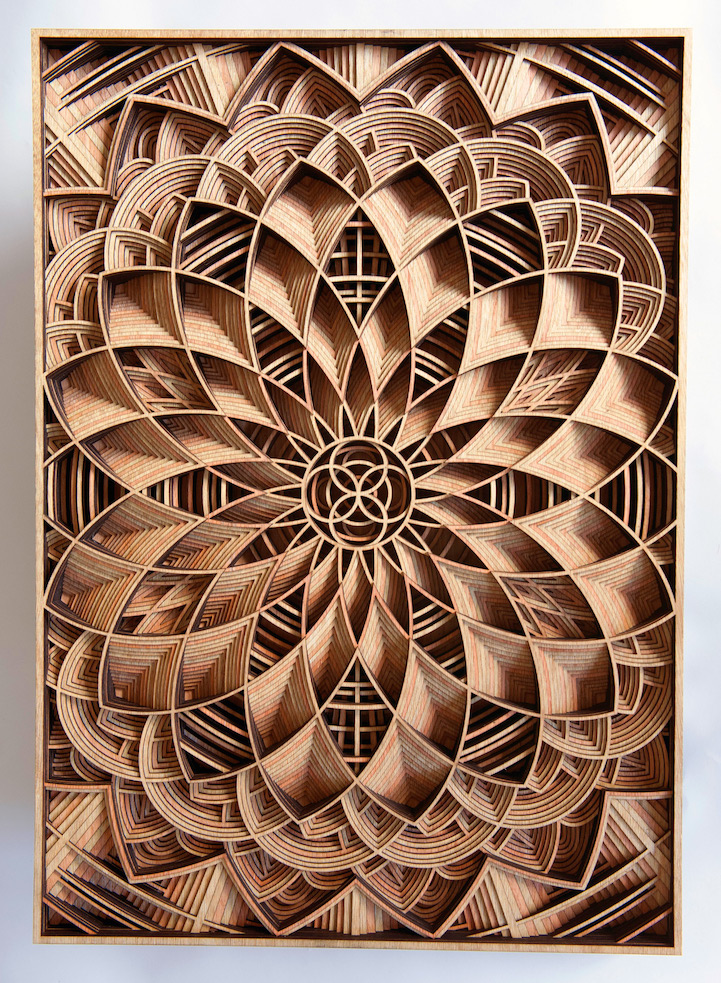

In the realm of manufacturing and design, the advent of 3D layered laser cutting has marked a paradigm shift. This innovative technique has enabled the creation of intricate and complex objects with unparalleled precision and detail. By combining multiple layers of material, 3D laser cutting offers a plethora of advantages, unlocking new possibilities for various industries.

Table of Content

H1: The Principles of 3D Layered Laser Cutting

- CAD Design: The desired object is designed using computer-aided design (CAD) software, creating a digital model.

- Material Preparation: The material to be cut is selected based on its properties and the desired outcome. It is then cut into flat sheets or layers.

- Laser Cutting: A laser beam is precisely guided to cut each layer according to the CAD design. The laser melts or vaporizes the material, creating intricate patterns and shapes.

- Layer Assembly: The cut layers are meticulously assembled and bonded together, forming the final three-dimensional object.

H2: Advantages of 3D Layered Laser Cutting

3D layered laser cutting offers numerous advantages over traditional manufacturing methods:

- Precision and Accuracy: Laser beams deliver exceptional precision, ensuring that each layer is cut with utmost accuracy. This enables the creation of highly intricate and detailed objects.

- 3d Laser Cutting Design 3D Laser Cutting Design: Revolutionizing Manufacturing And Creativity

- 3d And Laser Cut 3D And Laser Cutting: A Comprehensive Guide To Advanced Manufacturing Techniques

- Laser Cut 3d Puzzle Dxf Files Laser Cut 3D Puzzle DXF Files: An In-Depth Guide For Hobbyists And Designers

- 3d Laser Cut Invitations 3D Laser Cut Invitations: Elevate Your Events With Intricate Beauty

- Snapmaker Cnc Cutting Wood Snapmaker CNC: Unleashing Precision And Versatility For Woodworking

- CAD Design: The desired object is designed using computer-aided design (CAD) software, creating a digital model.

- Material Preparation: The material to be cut is selected based on its properties and the desired outcome. It is then cut into flat sheets or layers.

- Flexibility and Customization: The digital design process allows for easy customization of objects, catering to specific requirements and preferences.

- Material Versatility: 3D laser cutting can process a wide range of materials, including metals, plastics, wood, and even some fabrics.

- Speed and Efficiency: The laser cutting process is highly automated, resulting in faster production times and increased efficiency.

- Cost-Effectiveness: By eliminating the need for molds and dies, 3D laser cutting offers cost-effective production of low-volume or customized parts.

- Automotive: Intricate parts for vehicles, such as dashboards, interior trim, and lighting assemblies.

- Medical: Surgical instruments, prosthetics, and dental implants with complex geometries.

- Aerospace: Lightweight and durable components for aircraft and spacecraft.

- Consumer Products: Electronic devices, toys, and home décor with intricate designs and textures.

- Architecture: Decorative elements, lighting fixtures, and custom-made building components.

In the realm of manufacturing and design, the advent of 3D layered laser cutting has marked a paradigm shift. This innovative technique has enabled the creation of intricate and complex objects with unparalleled precision and detail. By combining multiple layers of material, 3D laser cutting offers a plethora of advantages, unlocking new possibilities for various industries.

H1: The Principles of 3D Layered Laser Cutting

3D layered laser cutting involves a multi-step process that transforms raw materials into three-dimensional objects. The process typically consists of the following steps:

H3: Applications of 3D Layered Laser Cutting

The versatility of 3D layered laser cutting has opened up a world of possibilities in various industries:

H2: Conclusion

3D layered laser cutting has emerged as a transformative technology in the manufacturing and design landscape. By combining precision, flexibility, and versatility, it enables the creation of complex objects that were once impossible to produce. As the technology continues to advance, it holds the promise of further innovation and disruption across a wide range of industries.

FAQs:

Q: What materials can be used in 3D layered laser cutting?

A: Metals, plastics, wood, and certain fabrics.

Q: Is 3D layered laser cutting faster than traditional manufacturing methods?

A: Yes, due to its automated process and elimination of mold and die fabrication.

Q: Can 3D layered laser cutting be used for mass production?

A: Yes, it can be used for both low-volume and mass production, depending on the specific application.