3D Laser Cut Objects: Revolutionizing Design and Manufacturing

Introduction

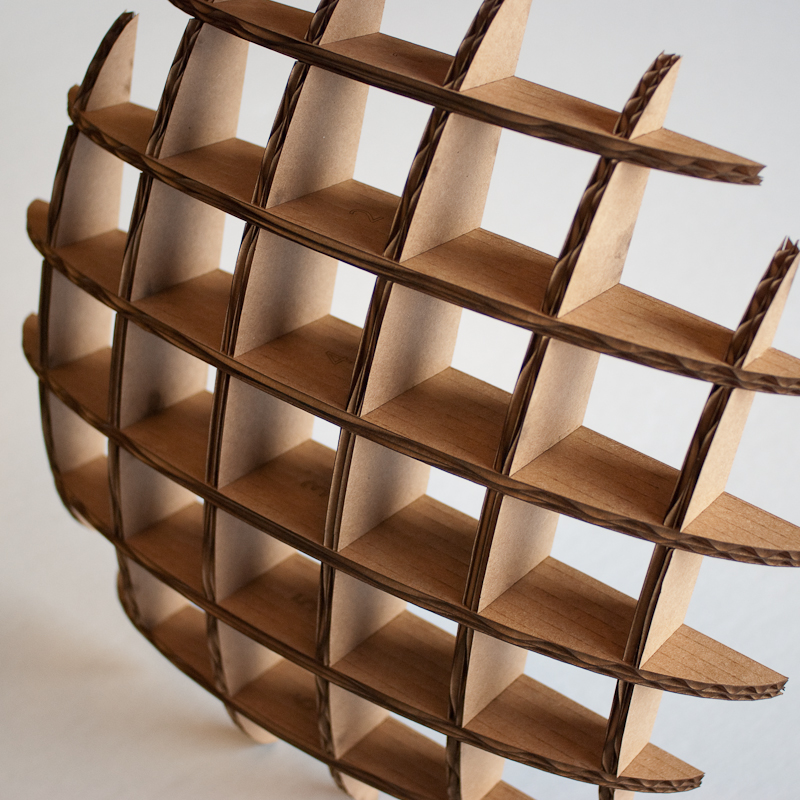

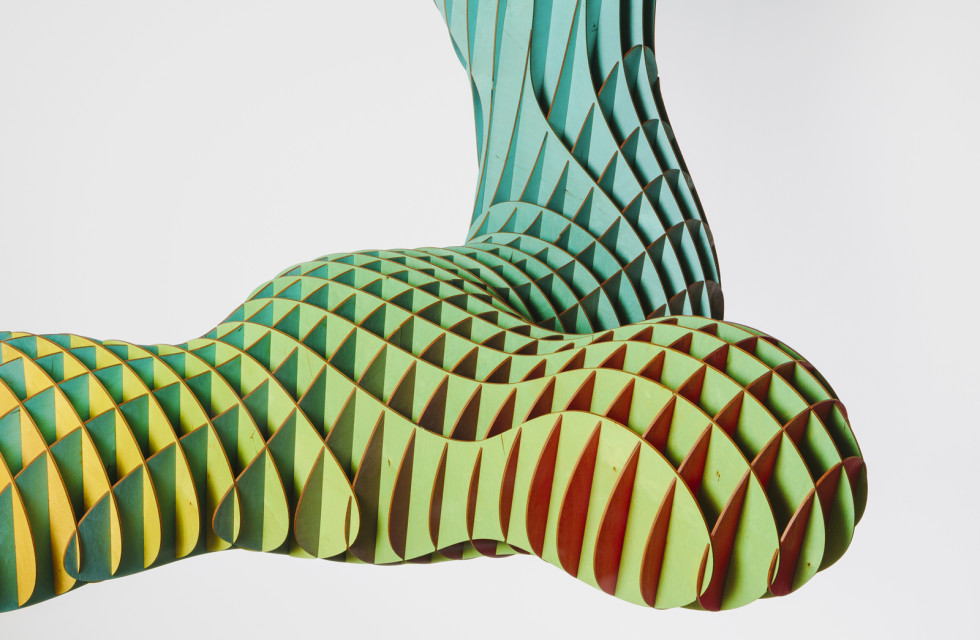

3D laser cutting technology has emerged as a transformative force in various industries, offering unparalleled precision, versatility, and speed in the creation of intricate and complex objects. From prototyping and design to manufacturing and customization, 3D laser cutting has revolutionized the way we approach product development and production.

Table of Content

Benefits of 3D Laser Cutting

- Laser cutters utilize highly focused beams of light to cut materials with extreme precision, resulting in sharp edges, smooth surfaces, and intricate details.

- This level of accuracy enables the creation of complex shapes and designs that would be challenging or impossible to achieve using traditional methods.

Versatility:

- 3D laser cutters can work with a wide range of materials, including metals, plastics, wood, and fabrics.

- This versatility allows for the production of objects for various applications, from industrial components to architectural elements and consumer products.

Speed and Efficiency:

3D laser cutting technology has emerged as a transformative force in various industries, offering unparalleled precision, versatility, and speed in the creation of intricate and complex objects. From prototyping and design to manufacturing and customization, 3D laser cutting has revolutionized the way we approach product development and production.

- Afinia Emblaser 2 Afinia Emblaser 2: A Comprehensive Guide To Laser Engraving And Cutting

- 3d Laser Cut Files Free 3D Laser Cut Files Free: Unleash Your Creativity

- 3d Laser Cut Wooden Puzzles 3D Laser Cut Wooden Puzzles: A Guide To Intricate And Enchanting Creations

- 3d Laser Cut Acrylic Letters 3D Laser Cut Acrylic Letters: A Comprehensive Guide

- 3d Laser Cutting Metal 3D Laser Cutting Metal: A Comprehensive Guide

Benefits of 3D Laser Cutting

Precision and Accuracy:

- Laser cutters utilize highly focused beams of light to cut materials with extreme precision, resulting in sharp edges, smooth surfaces, and intricate details.

- This level of accuracy enables the creation of complex shapes and designs that would be challenging or impossible to achieve using traditional methods.

- Laser cutting is a highly efficient process, with lasers capable of cutting materials at rapid speeds.

- This speed advantage enables the mass production of objects and reduces lead times, making it ideal for high-volume manufacturing.

- Laser cutters are extensively used in prototyping to quickly create physical models of designs.

- The precision and speed of laser cutting allow designers to iterate and refine their designs efficiently.

- 3D laser cutting has become an integral part of manufacturing processes for various industries.

- It enables the production of complex components, such as gears, brackets, and housings, with high accuracy and repeatability.

- Laser cutting allows for the customization of products to meet specific requirements.

- By laser cutting custom shapes and designs, manufacturers can create unique and personalized objects for consumers.

- 3D laser cutting is widely used in architecture to create intricate facades, decorative panels, and structural components.

- The precision and versatility of laser cutting enable the realization of complex architectural designs.

- Metals: Stainless steel, aluminum, brass, copper

- Plastics: Acrylic, polycarbonate, ABS, PVC

- Wood: Plywood, MDF, hardwood

- Fabrics: Leather, textiles, canvas

Applications of 3D Laser Cut Objects

Prototyping and Design:

Manufacturing:

Customization:

Architectural Elements:

Materials for 3D Laser Cutting

Factors to Consider When Laser Cutting

Material Thickness: The thickness of the material will determine the laser power and cutting speed required.

Material Type: Different materials have varying laser absorption and cutting characteristics.

Design Complexity: Intricate designs may require slower cutting speeds and higher laser power.

Surface Finish: The desired surface finish will influence the cutting parameters and post-processing techniques.

Conclusion

3D laser cutting technology has revolutionized the way we create and manufacture objects. Its precision, versatility, speed, and customization capabilities have made it an essential tool in various industries. As technology continues to advance, 3D laser cutting will undoubtedly play an even more significant role in shaping the future of design and manufacturing.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting involves cutting flat materials, while 3D laser cutting allows for the cutting of three-dimensional objects.

Q: Can laser cutters cut any material?

A: While laser cutters can work with a wide range of materials, they are not suitable for cutting all materials, such as glass or ceramics.

Q: How does the laser power affect the cutting process?

A: Higher laser power enables faster cutting speeds and the ability to cut thicker materials. However, it can also result in more heat-affected zones and potential material distortion.