3D Laser Cut Projects: Unleashing Creativity and Innovation

Introduction

Laser cutting technology has revolutionized the world of art, design, and manufacturing. By precisely directing a laser beam, intricate and complex designs can be etched or cut into a variety of materials, including wood, metal, acrylic, and fabric. This opens up endless possibilities for creating stunning 3D laser cut projects that combine precision, creativity, and functionality.

Table of Content

- 1 3D Laser Cut Projects: Unleashing Creativity and Innovation

- 1.1 Introduction

- 1.2 Understanding 3D Laser Cutting

- 1.3 Materials for 3D Laser Cutting

- 1.4 Understanding 3D Laser Cutting

- 1.5 Design Considerations for 3D Laser Cut Projects

- 1.6 Applications of 3D Laser Cut Projects

- 1.7 Benefits of 3D Laser Cutting

- 1.8 Conclusion

- 1.9 Frequently Asked Questions (FAQs)

Understanding 3D Laser Cutting

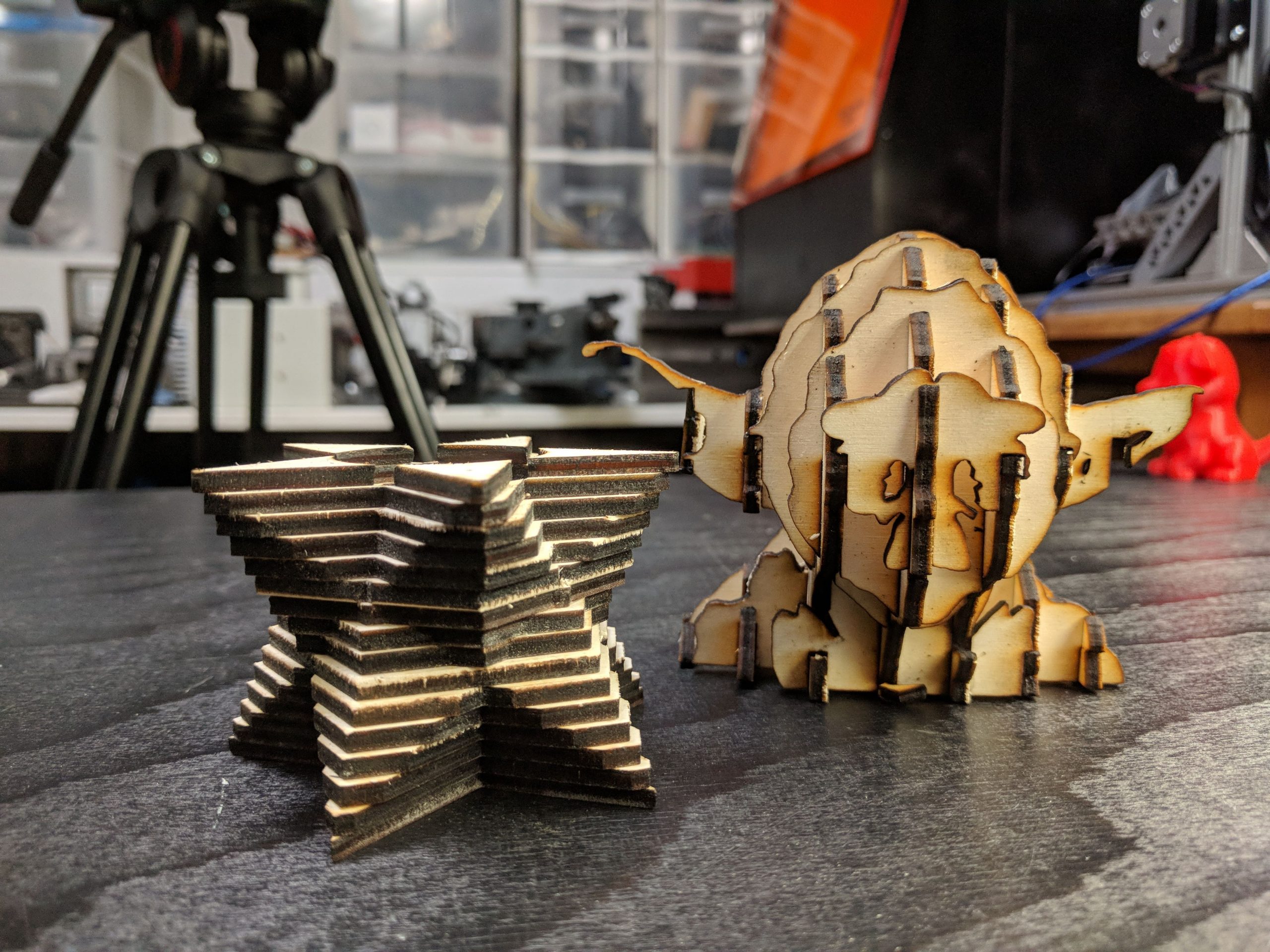

Unlike traditional 2D laser cutting, which operates on a flat plane, 3D laser cutting involves moving the laser beam along three axes (X, Y, and Z) to create three-dimensional objects. This allows for the creation of complex shapes and structures that would be impossible to achieve with manual methods.

Types of 3D Laser Cutters

There are various types of 3D laser cutters available, each with its own capabilities and limitations. Some common types include:

- CO2 Laser Cutters: Versatile and widely used, these cutters are suitable for cutting a wide range of materials.

- Fiber Laser Cutters: Offer high precision and cutting speeds, making them ideal for intricate designs and metalworking.

- Diode Laser Cutters: Small and portable, these cutters are suitable for smaller projects and engraving on thin materials.

Materials for 3D Laser Cutting

The choice of material for 3D laser cutting depends on the desired result and the capabilities of the laser cutter. Common materials used include:

Laser cutting technology has revolutionized the world of art, design, and manufacturing. By precisely directing a laser beam, intricate and complex designs can be etched or cut into a variety of materials, including wood, metal, acrylic, and fabric. This opens up endless possibilities for creating stunning 3D laser cut projects that combine precision, creativity, and functionality.

- Laser Cut 3d Pop Cards Laser Cut 3D Pop Cards: A Captivating Expression Of Creativity And Emotion

- 3 D Laser Cutting 3D Laser Cutting: A Revolutionary Technology For Precision Manufacturing

- 3d Laser Cut Art 3D Laser Cut Art: Unlocking A World Of Dimensional Creativity

- 3d Laser Cut Wooden Puzzles 3D Laser Cut Wooden Puzzles: A Guide To Intricate And Enchanting Creations

- Laser Cut 3d Maze Laser Cut 3D Maze: A Labyrinth Of Intricate Design

Understanding 3D Laser Cutting

What is 3D Laser Cutting?

Unlike traditional 2D laser cutting, which operates on a flat plane, 3D laser cutting involves moving the laser beam along three axes (X, Y, and Z) to create three-dimensional objects. This allows for the creation of complex shapes and structures that would be impossible to achieve with manual methods.

Types of 3D Laser Cutters

There are various types of 3D laser cutters available, each with its own capabilities and limitations. Some common types include:

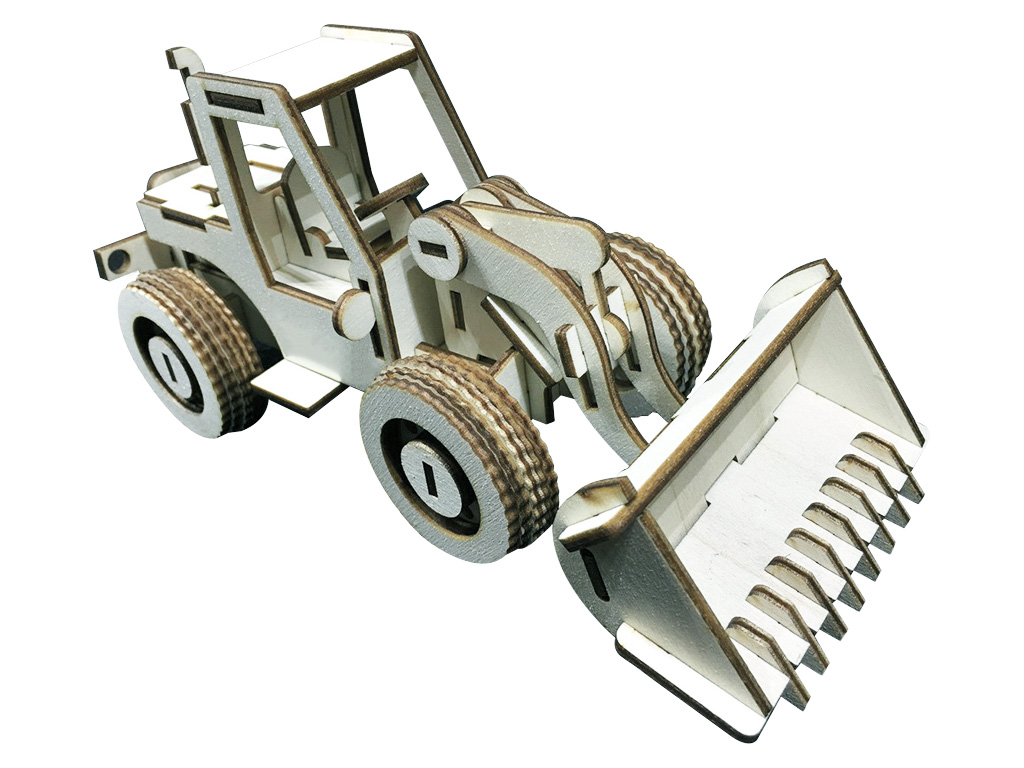

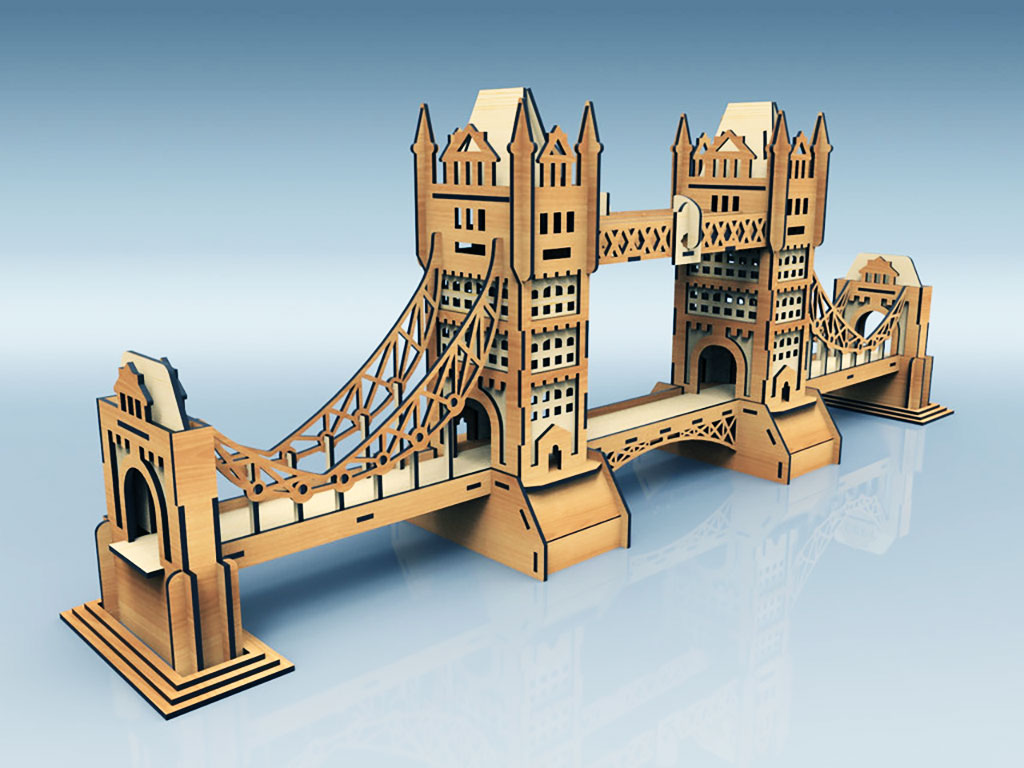

- Wood: Versatile and easy to cut, suitable for a wide range of projects from furniture to toys.

- Metal: Durable and resistant, ideal for industrial applications and decorative elements.

- Acrylic: Clear and lightweight, suitable for lighting fixtures, display stands, and signage.

- Fabric: Can be cut or engraved to create intricate designs on textiles, leather, and other fabrics.

Design Considerations for 3D Laser Cut Projects

Design Software:

3D laser cutting projects require the use of specialized design software to create the necessary 3D models. Popular software options include AutoCAD, SolidWorks, and SketchUp.

Joint Design:

The design of the joints between the individual components of the 3D object is crucial for its structural integrity and functionality. Common joint types include dovetails, finger joints, and interlocking tabs.

Material Thickness:

The thickness of the material used determines the depth of the laser cut and the overall strength of the object. Thicker materials require higher laser power and longer cutting times.

Applications of 3D Laser Cut Projects

3D laser cutting has a wide range of applications in various industries and domains, including:

- Art and Design: Creating sculptures, wall art, and other decorative pieces.

- Architecture and Construction: Fabrication of architectural models, custom lighting fixtures, and structural components.

- Industrial Manufacturing: Production of precision parts, prototypes, and custom machinery.

- Fashion and Textiles: Cutting and engraving fabrics for clothing, accessories, and home décor.

- Personalized Gifts and Decor: Creating unique and meaningful gifts, home décor, and personalized items.

Benefits of 3D Laser Cutting

- Precision and Accuracy: Laser cutting ensures precise and accurate cuts, resulting in high-quality products.

- Intricate Designs: Complex and intricate designs can be created with ease, allowing for unique and innovative products.

- Automation: Laser cutters can be automated, increasing production efficiency and reducing labor costs.

- Versatility: Laser cutting can be used on a wide range of materials, making it suitable for a variety of applications.

- Cost-Effectiveness: Laser cutting can be cost-effective for both small and large production runs.

Conclusion

3D laser cutting technology has transformed the world of manufacturing and design, enabling the creation of intricate and functional objects with unparalleled precision and versatility. From art and architecture to industrial manufacturing and personalized gifts, the applications of 3D laser cut projects are boundless. As technology continues to advance, we can expect even more innovative and groundbreaking uses for this remarkable technology.

Frequently Asked Questions (FAQs)

Q: What is the difference between 3D laser cutting and 2D laser cutting?

A: 3D laser cutting involves moving the laser beam along three axes (X, Y, and Z), allowing for the creation of three-dimensional objects. 2D laser cutting operates on a flat plane, creating two-dimensional designs.

Q: What are the most common materials used for 3D laser cutting?

A: Wood, metal, acrylic, and fabric are the most widely used materials for 3D laser cutting.

Q: What design software is recommended for 3D laser cut projects?

A: AutoCAD, SolidWorks, and SketchUp are popular software options for creating 3D models for laser cutting.

Q: Is 3D laser cutting suitable for both small and large production runs?

A: Yes, laser cutting can be cost-effective for both small and large production runs, depending on the specific requirements of the project.

Q: What safety precautions should be taken when using a 3D laser cutter?

A: Always wear appropriate safety gear, such as goggles, gloves, and a respirator. Ensure the work area is well-ventilated and follow the manufacturer’s instructions for safe operation.