3D Laser Cut Price: A Comprehensive Guide to Cost Considerations

Introduction

3D laser cutting technology has revolutionized various industries, offering precision, efficiency, and versatility in manufacturing complex parts. However, understanding the cost associated with 3D laser cutting is crucial for businesses and individuals seeking to utilize this technology. This article delves into the various factors that influence 3D laser cut price, providing a comprehensive guide to help you make informed decisions.

Table of Content

- 1 3D Laser Cut Price: A Comprehensive Guide to Cost Considerations

- 1.1 Introduction

- 1.2 Factors Affecting 3D Laser Cut Price

- 1.2.1 2. Laser Type and Power

- 1.2.2 3. Design Complexity

- 1.2.3 4. Volume and Quantity

- 1.2.4 5. Finishing and Post-Processing

- 1.3 Calculating 3D Laser Cut Price

- 1.4 Factors Affecting 3D Laser Cut Price

- 1.4.5 1. Material Type and Thickness

- 1.4.6 2. Laser Type and Power

- 1.5 Tips for Reducing 3D Laser Cut Price

- 1.6 Conclusion

- 1.7 FAQs

Factors Affecting 3D Laser Cut Price

The type and thickness of the material being cut significantly impact the cost. Harder materials, such as metals, require higher laser power and longer processing times, resulting in higher costs. Thicker materials also require more passes of the laser, increasing the overall cost.

2. Laser Type and Power

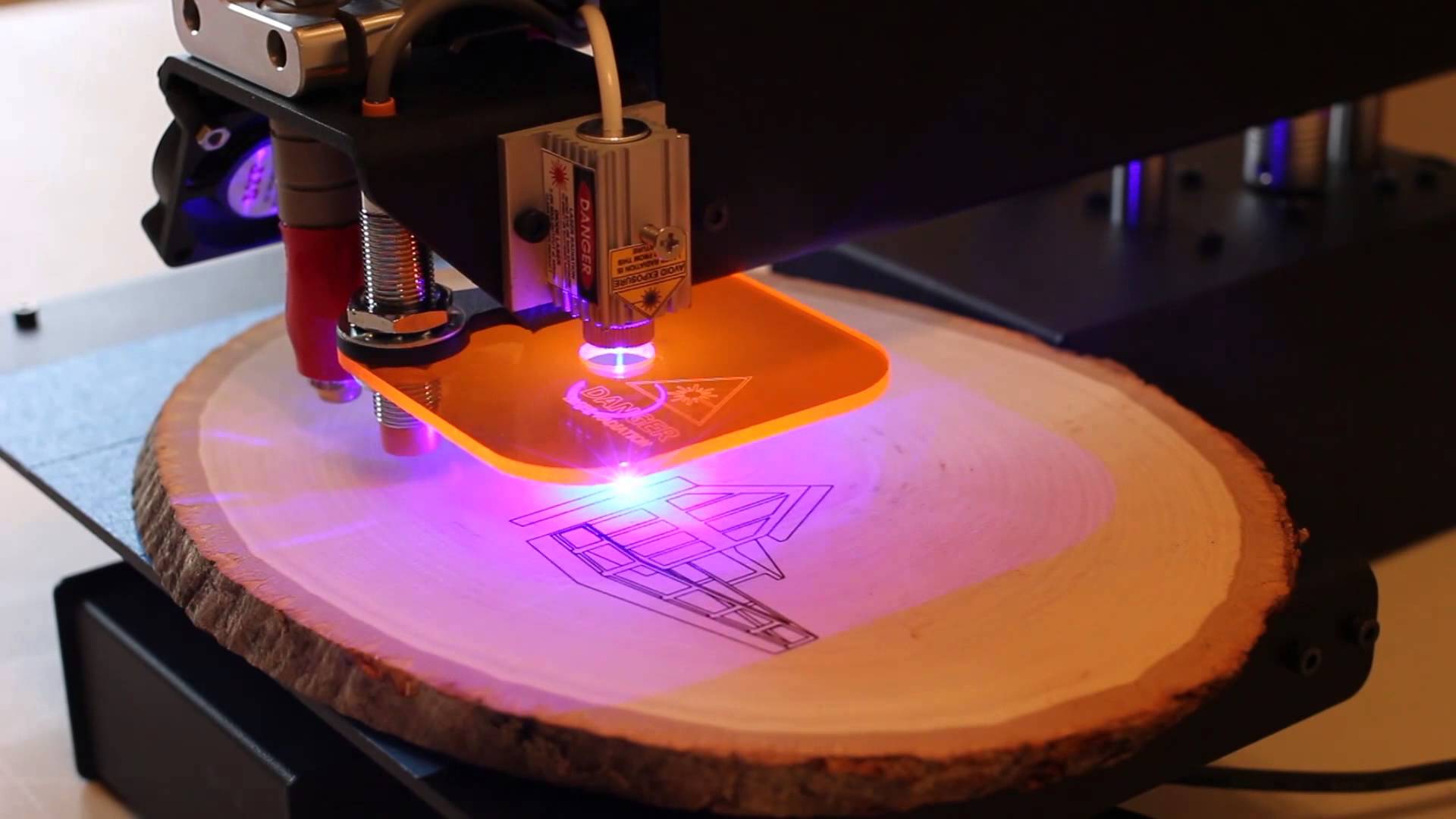

The type of laser used (e.g., CO2, fiber, or diode) and its power determine the cutting speed and precision. Higher-power lasers can cut thicker materials faster, but they come with a higher price tag.

3. Design Complexity

The complexity of the design affects the time and effort required to program the laser cutter. Intricate designs with small features or tight tolerances demand more precise laser control, leading to higher costs.

4. Volume and Quantity

The number of parts being cut and the overall volume of the order influence the price. High-volume orders often benefit from economies of scale, reducing the cost per part.

5. Finishing and Post-Processing

Additional finishing processes, such as deburring, polishing, or anodizing, can add to the overall cost. Post-processing requirements should be considered when budgeting for 3D laser cutting.

Calculating 3D Laser Cut Price

3D laser cutting technology has revolutionized various industries, offering precision, efficiency, and versatility in manufacturing complex parts. However, understanding the cost associated with 3D laser cutting is crucial for businesses and individuals seeking to utilize this technology. This article delves into the various factors that influence 3D laser cut price, providing a comprehensive guide to help you make informed decisions.

- 3d Laser Cutter Projects 3D Laser Cutter Projects: Unleashing Creativity And Precision

- 3d Laser Cut Cat 3D Laser Cut Cat: A Unique And Personalized Home Decor

- Laser Cut 3d Horse Laser Cut 3D Horse: A Detailed Guide To Creating Intricate Equestrian Art

- 3d Laser Cut Car 3D Laser Cut Car: A Comprehensive Guide To Precision And Customization

- Sketchup Laser Cutting H1: Unleashing The Power Of SketchUp Laser Cutting: A Comprehensive Guide

Factors Affecting 3D Laser Cut Price

1. Material Type and Thickness

The type and thickness of the material being cut significantly impact the cost. Harder materials, such as metals, require higher laser power and longer processing times, resulting in higher costs. Thicker materials also require more passes of the laser, increasing the overall cost.

2. Laser Type and Power

The type of laser used (e.g., CO2, fiber, or diode) and its power determine the cutting speed and precision. Higher-power lasers can cut thicker materials faster, but they come with a higher price tag.

The calculation of 3D laser cut price involves considering the following factors:

- Material cost: The cost of the raw material per unit area.

- Laser cutting time: The time required to cut the design, based on material thickness, laser power, and design complexity.

- Labor cost: The cost of operating the laser cutter and performing any necessary post-processing.

- Overhead costs: Fixed expenses such as rent, utilities, and equipment maintenance.

- Profit margin: The percentage of profit desired by the service provider.

Tips for Reducing 3D Laser Cut Price

- Optimize design: Simplify the design to reduce cutting time and material waste.

- Choose the right material: Consider using less expensive materials or exploring alternative cutting methods.

- Negotiate volume discounts: Order larger quantities to take advantage of economies of scale.

- Compare quotes from multiple vendors: Obtain quotes from several service providers to find the best price for your specific requirements.

- Explore alternative cutting technologies: Consider using waterjet cutting or CNC milling for certain materials or designs.

Conclusion

Understanding the factors that affect 3D laser cut price is essential for making informed decisions and budgeting effectively. By considering material type, laser specifications, design complexity, volume, and finishing requirements, you can estimate the cost of your project accurately. Additionally, optimizing designs, exploring alternative materials, and negotiating volume discounts can help reduce the overall cost.

FAQs

Q: What is the typical cost range for 3D laser cutting?

A: The cost can vary greatly depending on the factors discussed above. Generally, prices range from a few dollars to hundreds of dollars per square foot.

Q: Can I cut any material with a 3D laser cutter?

A: Most common materials, including metals, plastics, and wood, can be cut with 3D laser cutters. However, the suitability of specific materials depends on the laser type and power.

Q: How do I find a reliable 3D laser cutting service provider?

A: Look for companies with experience in your industry, positive customer reviews, and a proven track record of quality and precision.