Laser Cut vs 3D Printer: A Comprehensive Guide

When it comes to creating custom objects, laser cutting and 3D printing are two popular technologies that offer distinct advantages and limitations. Understanding the differences between these two methods is crucial for making an informed decision based on your specific needs.

H1: Laser Cutting vs 3D Printer

Table of Content

- 1 Laser Cut vs 3D Printer: A Comprehensive Guide

- 1.1 H1: Laser Cutting vs 3D Printer

- 1.2 H2: What is Laser Cutting?

- 1.3 H1: Laser Cutting vs 3D Printer

- 1.4 H2: What is Laser Cutting?

- 1.5 H2: What is 3D Printing?

- 1.6 H3: Comparison of Key Features

- 1.7 H2: Choosing the Right Technology

- 1.8 H2: Applications

- 1.9 H3: Conclusion

- 1.10 FAQs

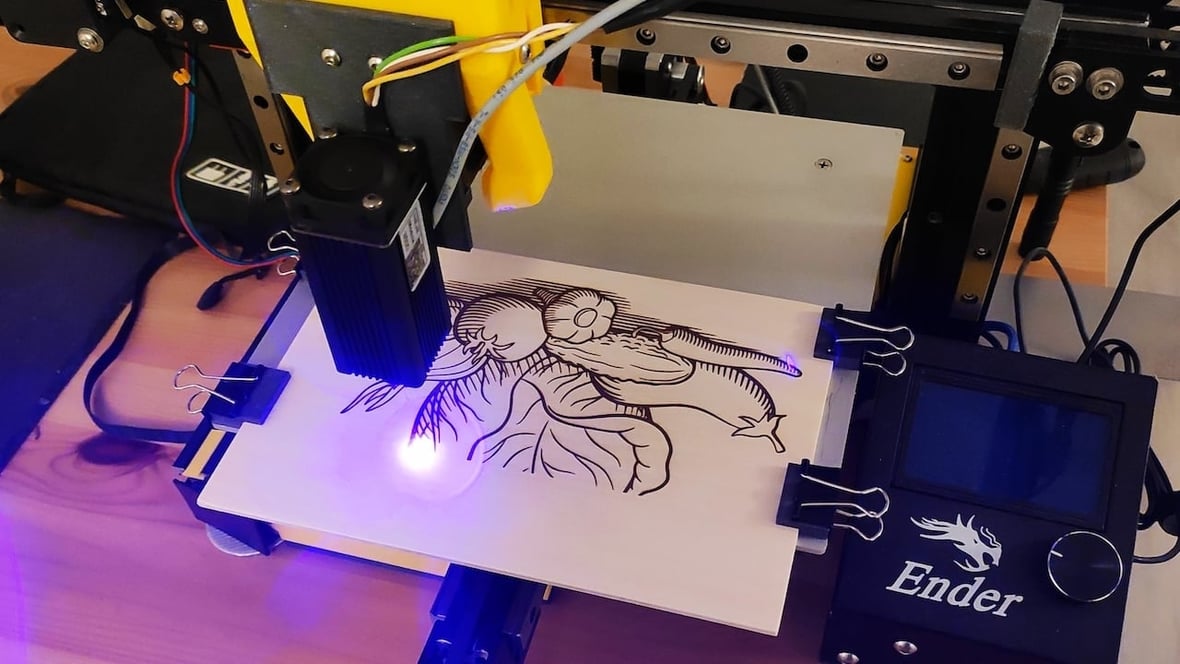

H2: What is Laser Cutting?

Advantages of Laser Cutting:

- Precision: Laser cutting offers unparalleled precision, enabling the creation of intricate designs with sharp edges.

- Speed: Laser cutters can cut materials at high speeds, making them suitable for mass production.

- Versatility: Laser cutting can be used on a wide range of materials, providing flexibility in design and application.

Disadvantages of Laser Cutting:

- Limited Thickness: Laser cutting is limited to thin materials, typically up to a few millimeters in thickness.

- Material Constraints: Certain materials, such as ceramics and glass, are not suitable for laser cutting.

- Sketchup Laser Cutting H1: Unleashing The Power Of SketchUp Laser Cutting: A Comprehensive Guide

- 3d Laser Cut Bee 3D Laser Cut Bee: A Buzzing Masterpiece Of Precision And Creativity

- 3d Laser Cut Model 3D Laser Cut Models: A Comprehensive Guide

- Laser Cut 3d Puzzle Dxf Files Laser Cut 3D Puzzle DXF Files: An In-Depth Guide For Hobbyists And Designers

- Laser Cut 3d Printer Enclosure Laser Cut 3D Printer Enclosure: A Comprehensive Guide

- Precision: Laser cutting offers unparalleled precision, enabling the creation of intricate designs with sharp edges.

- Fumes: Laser cutting can produce fumes, requiring proper ventilation systems.

- Complex Geometries: 3D printing allows for the creation of complex geometries and organic shapes that are difficult to achieve with traditional manufacturing methods.

- Prototyping and Customization: 3D printing is ideal for prototyping and creating custom objects, enabling rapid design iterations.

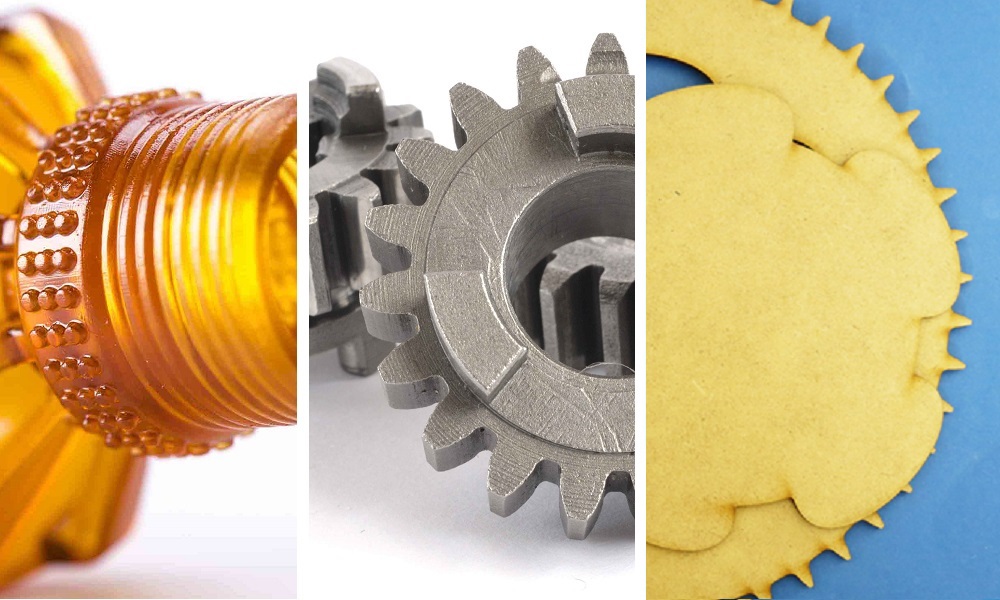

- Material Options: 3D printers can use a wide range of materials, including plastics, metals, and composites.

- Speed: 3D printing can be slow compared to laser cutting, especially for large objects.

- Surface Finish: 3D printed objects may have a rough surface finish, requiring post-processing for a smoother appearance.

- Limited Strength: Some 3D printed materials may have limited strength and durability.

- Material: Consider the material you need to cut or print. Laser cutting is suitable for thin materials, while 3D printing can handle thicker materials.

- Precision: If high precision is required, laser cutting is the better choice.

- Speed: For mass production, laser cutting offers higher speeds.

- Complexity: For complex shapes and organic geometries, 3D printing is more suitable.

- Budget: Laser cutting is typically more expensive than 3D printing for small-scale projects.

- Fabrication of metal parts

- Engraving and etching

- Textile cutting

- Product prototyping

- Prototyping and design

- Manufacturing of custom parts

- Medical implants

- Jewelry making

H1: Laser Cutting vs 3D Printer

H2: What is Laser Cutting?

Laser cutting involves directing a high-powered laser beam onto a material, causing it to vaporize and cut through it. This process is commonly used to create precise cuts in various materials, including wood, acrylic, metal, and leather.

Advantages of Laser Cutting:

H2: What is 3D Printing?

3D printing involves building an object layer by layer using a variety of materials, such as plastic, metal, and ceramic. The process begins with a digital 3D model, which is sliced into thin layers. The printer then deposits material onto the build platform, creating the object one layer at a time.

Advantages of 3D Printing:

Disadvantages of 3D Printing:

H3: Comparison of Key Features

| Feature | Laser Cutting | 3D Printing |

|---|---|---|

| Precision | High | Moderate |

| Speed | Fast | Slow |

| Versatility | Wide range of materials | Limited materials |

| Thickness | Thin materials | Any thickness |

| Complexity | Simple shapes | Complex shapes |

| Prototyping | Limited | Suitable for prototyping |

| Customization | Limited | High |

| Surface Finish | Smooth | Rough |

| Strength | High | Moderate to low |

H2: Choosing the Right Technology

The choice between laser cutting and 3D printing depends on several factors, including:

H2: Applications

Laser cutting and 3D printing have numerous applications in various industries:

Laser Cutting:

3D Printing:

H3: Conclusion

Laser cutting and 3D printing are both powerful technologies that offer unique advantages and limitations. By understanding the differences between these methods, you can make an informed decision based on your specific requirements. Laser cutting is ideal for precise, high-speed cutting of thin materials, while 3D printing is suitable for creating complex geometries and prototypes. Both technologies have their place in various industries, enabling the creation of innovative and custom products.

FAQs

Q: Which technology is better for home use?

A: 3D printing is more accessible and affordable for home use, while laser cutting requires specialized equipment and ventilation systems.

Q: Can laser cutters cut glass?

A: Yes, but only certain types of glass and with specialized laser systems.

Q: What materials can 3D printers use?

A: 3D printers can use various materials, including plastics, metals, composites, and ceramics.

Q: Is 3D printing stronger than laser cutting?

A: Laser cutting typically results in stronger cuts, while 3D printed materials may have limited strength depending on the material used.

Q: Which technology is more environmentally friendly?

A: 3D printing produces less waste than laser cutting, as the excess material can be reused.