Laser Cut 3D Shapes: Transforming Designs into Tangible Masterpieces

Introduction

Laser cutting technology has revolutionized the manufacturing industry, enabling the creation of intricate and precise three-dimensional (3D) shapes. By directing a focused beam of light onto a material, laser cutting machines can cut complex patterns with high accuracy and detail. This article explores the process, applications, and benefits of laser cut 3D shapes, providing insights into how this technology is transforming designs into tangible masterpieces.

Table of Content

Laser Cutting Process

- Design creation: A 3D model of the desired shape is created using computer-aided design (CAD) software.

- Material selection: The material to be cut is chosen based on its compatibility with the laser cutting process.

- Laser beam generation: A laser beam is generated by a high-power laser source.

- Material interaction: The laser beam is focused onto the material, causing it to vaporize or melt along the desired cutting path.

- Shape formation: The laser beam follows the designed pattern, cutting the material into the desired 3D shape.

Applications of Laser Cut 3D Shapes

Laser cut 3D shapes find applications in a wide range of industries, including:

- Laser 3d Cutter Laser 3D Cutter: A Comprehensive Guide

- 3d Laser Cut Objects 3D Laser Cut Objects: Revolutionizing Design And Manufacturing

- 3d Laser Cut Christmas Tree 3D Laser Cut Christmas Tree: A Modern And Sustainable Holiday Decoration

- Sculpteo Laser Cutting Sculpteo Laser Cutting: A Comprehensive Guide To Precision Manufacturing

- 3 D Laser Cutting 3D Laser Cutting: A Revolutionary Technology For Precision Manufacturing

- Design creation: A 3D model of the desired shape is created using computer-aided design (CAD) software.

- Material selection: The material to be cut is chosen based on its compatibility with the laser cutting process.

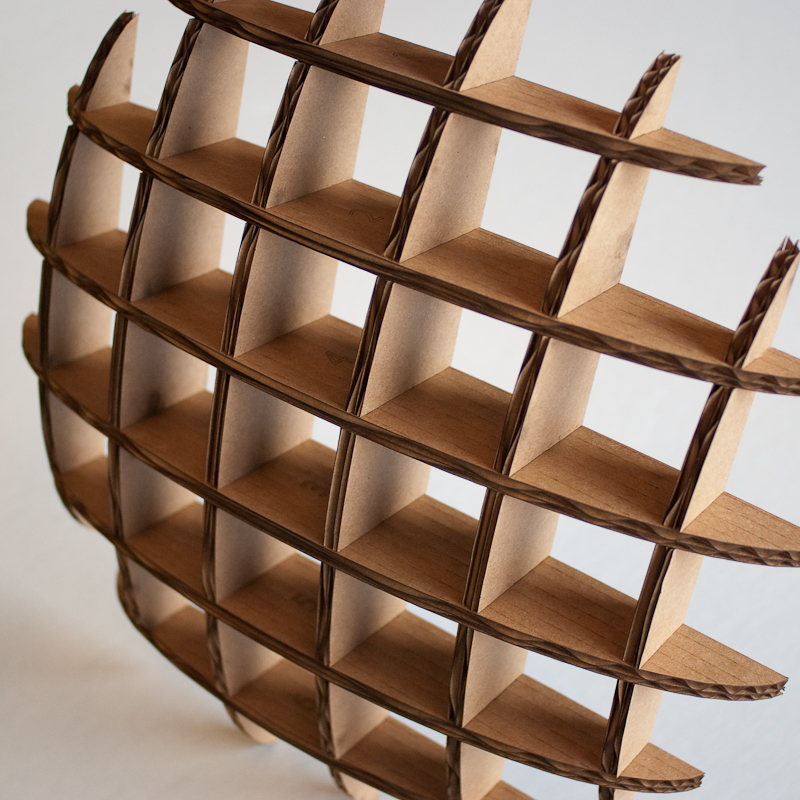

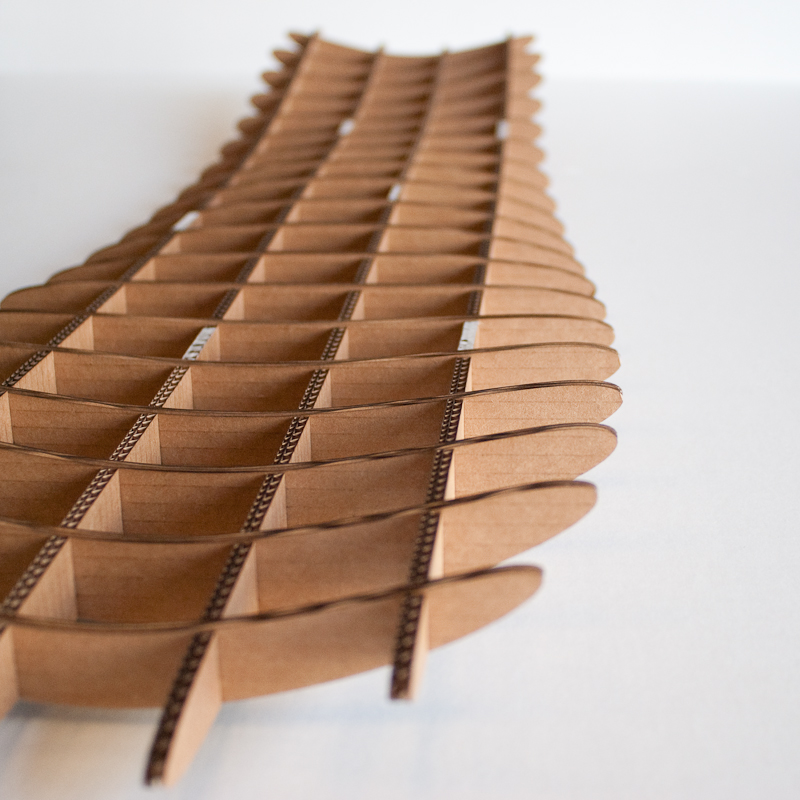

- Architecture: Creating architectural models, sculptures, and decorative elements.

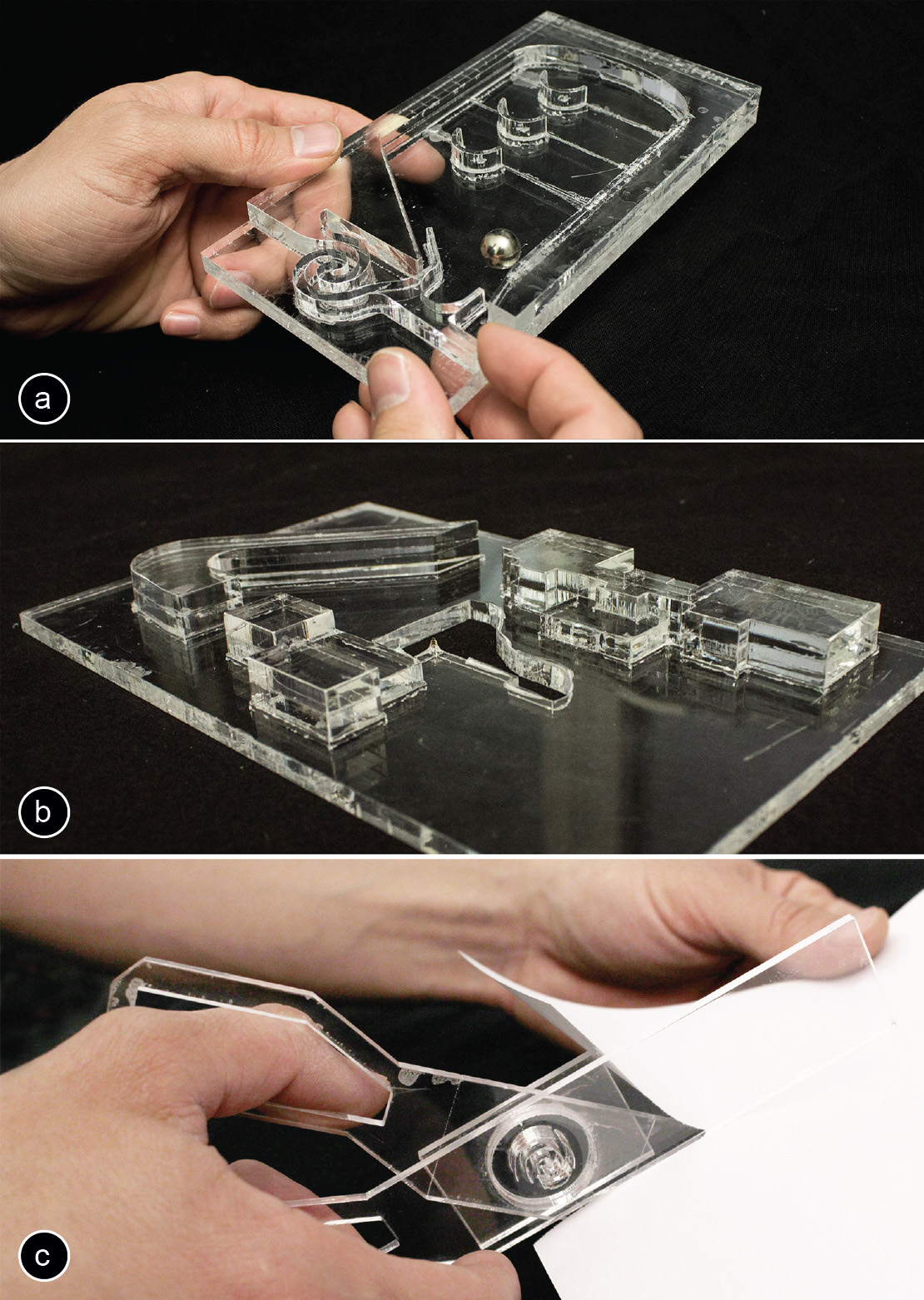

- Industrial design: Designing and manufacturing prototypes, molds, and production parts.

- Automotive: Producing lightweight and durable components for vehicles.

- Aerospace: Fabricating complex parts for aircraft and spacecraft.

- Consumer products: Creating customized products, such as jewelry, toys, and home décor.

- Precision and accuracy: Laser cutting machines can cut intricate patterns with high precision and accuracy, ensuring dimensional consistency.

- Complex geometries: Laser cutting enables the creation of complex 3D shapes that would be difficult or impossible to produce using traditional methods.

- Speed and efficiency: Laser cutting is a fast and efficient process, reducing production time and increasing output.

- Material versatility: Laser cutting can be used on a wide range of materials, including metals, plastics, wood, and fabrics.

- Customization: Laser cutting allows for the production of custom-made 3D shapes, tailored to specific requirements.

- Metals: Stainless steel, aluminum, titanium, and brass.

- Plastics: Acrylic, polycarbonate, and polyethylene.

- Wood: Plywood, MDF, and hardwoods.

- Fabrics: Leather, canvas, and synthetic textiles.

Laser cutting technology has revolutionized the manufacturing industry, enabling the creation of intricate and precise three-dimensional (3D) shapes. By directing a focused beam of light onto a material, laser cutting machines can cut complex patterns with high accuracy and detail. This article explores the process, applications, and benefits of laser cut 3D shapes, providing insights into how this technology is transforming designs into tangible masterpieces.

Laser Cutting Process

The laser cutting process involves the following steps:

Benefits of Laser Cut 3D Shapes

Laser cut 3D shapes offer numerous benefits:

Materials for Laser Cutting

The choice of material for laser cutting depends on the desired properties and application of the 3D shape. Common materials include:

Conclusion

Laser cutting 3D shapes has become an essential technology in the manufacturing industry, enabling the creation of complex and precise designs with speed, efficiency, and customization. From architectural models to industrial prototypes and consumer products, laser cut 3D shapes are transforming designs into tangible masterpieces, revolutionizing the way we create and interact with the world around us.

FAQs

Q: What is the maximum thickness of material that can be laser cut?

A: The maximum thickness depends on the laser power and material type. Typically, metal sheets up to 25mm thick can be laser cut, while plastics can be cut up to 20mm thick.

Q: Can laser cutting be used to create hollow shapes?

A: Yes, laser cutting can create hollow shapes by cutting along a closed path. The depth of the cut will determine the thickness of the shape’s walls.

Q: How do I prepare a 3D model for laser cutting?

A: The 3D model should be exported in a compatible file format, such as STL or DXF. Ensure that the model is closed and free of any overlapping or self-intersecting surfaces.

Q: What are the safety precautions for laser cutting?

A: Laser cutting involves high-power lasers, so safety precautions must be followed. These include wearing protective eyewear, ensuring proper ventilation, and avoiding exposure to the laser beam.