3D Laser Scanner: Revolutionizing Measurement and Inspection

Introduction

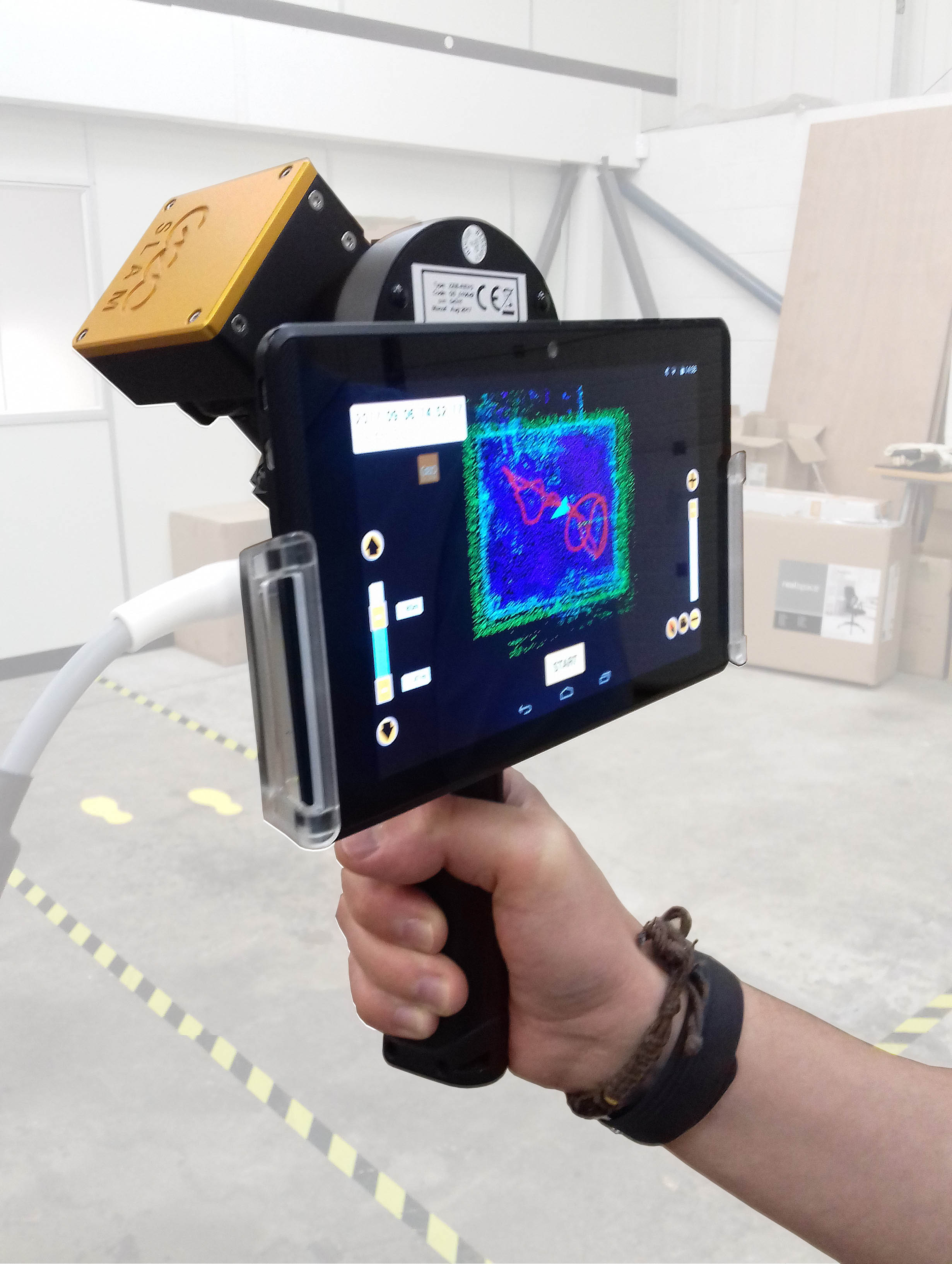

In the realm of measurement and inspection, the advent of 3D laser scanners has brought about a transformative shift. These cutting-edge devices harness the power of laser technology to capture precise and detailed 3D representations of physical objects, enabling a wide range of applications across industries. This article delves into the intricacies of 3D laser scanning, exploring its principles, types, applications, and the benefits it offers in various sectors.

Table of Content

- 1 3D Laser Scanner: Revolutionizing Measurement and Inspection

- 1.1 Introduction

- 1.2 H1: Understanding 3D Laser Scanning

- 1.3 H2: Types of 3D Laser Scanners

- 1.4 H3: Applications of 3D Laser Scanning

- 1.5 H1: Understanding 3D Laser Scanning

- 1.6 H2: Types of 3D Laser Scanners

- 1.7 H1: Benefits of 3D Laser Scanning

- 1.8 H1: Discussion and Conclusion

- 1.9 H1: FAQs

H1: Understanding 3D Laser Scanning

H2: Types of 3D Laser Scanners

Depending on the application requirements, there are various types of 3D laser scanners available:

- Triangulation Scanners: These scanners project a laser beam onto the object’s surface and measure the angle of reflection to determine the object’s shape.

- Time-of-Flight Scanners: These scanners emit a laser pulse and measure the time it takes for the reflected pulse to return, calculating the distance to the object’s surface.

- Phase-Shift Scanners: These scanners project a modulated laser beam onto the object and analyze the phase shift of the reflected beam to determine the object’s shape.

H3: Applications of 3D Laser Scanning

3D laser scanning finds application in a multitude of industries, including:

- Laser Cut 3d Illusion Lamp Laser Cut 3D Illusion Lamp: A Captivating And Personalized Lighting Experience

- Laser Cut 3d Angel Laser Cut 3D Angel: A Celestial Masterpiece For Home Decor And Gift Giving

- 3d Laser Cutter Projects 3D Laser Cutter Projects: Unleashing Creativity And Precision

- Sculpteo Laser Cutting Sculpteo Laser Cutting: A Comprehensive Guide To Precision Manufacturing

- 3d Cnc Cutting Design 3D CNC Cutting Design: A Comprehensive Guide

- Manufacturing: Reverse engineering, quality control, inspection

- Construction: Architectural documentation, as-built surveys

- Architecture: Building design, historical preservation

- Automotive: Vehicle design, crash testing

- Healthcare: Medical imaging, prosthetics design

- Forensics: Crime scene reconstruction, evidence gathering

- Accuracy and Precision: 3D laser scanners provide highly accurate and precise measurements, enabling detailed analysis of complex objects.

- Non-Contact Measurement: The non-contact nature of 3D laser scanning eliminates the risk of damaging fragile or delicate objects.

- Speed and Efficiency: 3D laser scanners capture data rapidly, reducing inspection and measurement time significantly.

- Data Richness: 3D laser scanners provide comprehensive data about an object’s shape, texture, and color, allowing for thorough analysis.

- Versatility: 3D laser scanners can be used to scan a wide range of objects, from small components to large structures.

In the realm of measurement and inspection, the advent of 3D laser scanners has brought about a transformative shift. These cutting-edge devices harness the power of laser technology to capture precise and detailed 3D representations of physical objects, enabling a wide range of applications across industries. This article delves into the intricacies of 3D laser scanning, exploring its principles, types, applications, and the benefits it offers in various sectors.

H1: Understanding 3D Laser Scanning

3D laser scanning is a non-contact measurement technique that utilizes a laser beam to scan the surface of an object. As the laser beam strikes the object, it reflects back to the scanner, providing information about the object’s geometry and shape. The scanner software then processes this data to generate a highly accurate 3D model of the object.

H2: Types of 3D Laser Scanners

Depending on the application requirements, there are various types of 3D laser scanners available:

H1: Benefits of 3D Laser Scanning

H1: Discussion and Conclusion

3D laser scanning has become an indispensable tool for measurement and inspection tasks, offering unparalleled accuracy, speed, and versatility. As technology continues to advance, we can expect to see even more innovative applications and benefits from 3D laser scanning in the years to come.

H1: FAQs

Q: What is the difference between 3D laser scanning and photogrammetry?

A: 3D laser scanning uses laser technology to capture data, while photogrammetry uses multiple photographs to generate 3D models. Laser scanning provides more accurate and detailed data.

Q: How much does a 3D laser scanner cost?

A: The cost of a 3D laser scanner varies depending on the type, accuracy, and features. Entry-level scanners can range from a few thousand dollars, while high-end scanners can cost hundreds of thousands of dollars.

Q: What are the limitations of 3D laser scanning?

A: 3D laser scanning can be limited by the object’s surface properties, such as reflectivity and transparency. Additionally, complex geometries may require multiple scans from different angles to capture complete data.