3D Laser Cutting UK: The Ultimate Guide to Precision Manufacturing

Introduction

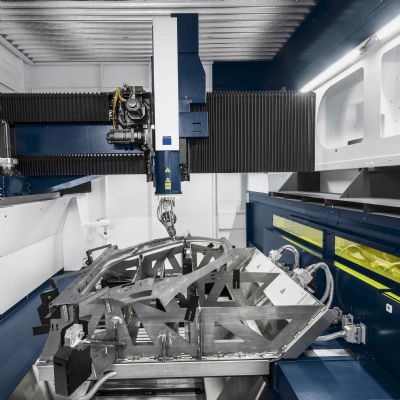

3D laser cutting is a revolutionary manufacturing technique that has transformed various industries, offering unparalleled precision, speed, and design flexibility. In the United Kingdom, the demand for 3D laser cutting services has surged, catering to diverse sectors such as aerospace, automotive, healthcare, and consumer electronics. This comprehensive guide delves into the world of 3D laser cutting UK, providing a detailed overview of its capabilities, applications, and benefits.

Table of Content

- 1 3D Laser Cutting UK: The Ultimate Guide to Precision Manufacturing

- 1.1 Introduction

- 1.2 What is 3D Laser Cutting?

- 1.3 Advantages of 3D Laser Cutting

- 1.4 Applications of 3D Laser Cutting

- 1.5 What is 3D Laser Cutting?

- 1.6 Advantages of 3D Laser Cutting

- 1.7 Choosing a 3D Laser Cutting Service Provider in the UK

- 1.8 Conclusion

- 1.9 FAQs

What is 3D Laser Cutting?

Advantages of 3D Laser Cutting

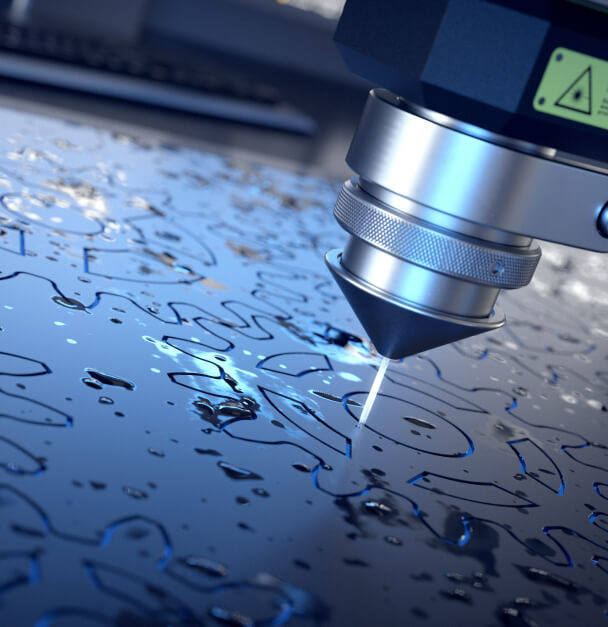

Precision and Accuracy: 3D laser cutting offers unmatched precision, ensuring dimensional accuracy and intricate details. The laser’s tight beam control allows for precise cuts and complex geometries.

Speed and Efficiency: Laser cutting is a rapid process, significantly reducing production time compared to traditional methods. Automated systems and advanced software optimize the cutting process for maximum efficiency.

Material Versatility: 3D laser cutting can handle a wide range of materials, including ferrous and non-ferrous metals, plastics, composites, and wood. This versatility makes it suitable for diverse applications.

Design Flexibility: The digital nature of 3D laser cutting allows for complete design freedom. Complex shapes, intricate patterns, and intricate details can be easily created and produced with high repeatability.

Reduced Waste and Environmental Impact: Unlike traditional cutting methods, 3D laser cutting produces minimal waste, as the laser beam melts and vaporizes the material rather than removing it physically. This reduces material consumption and environmental impact.

Applications of 3D Laser Cutting

3D laser cutting finds application in numerous industries, including:

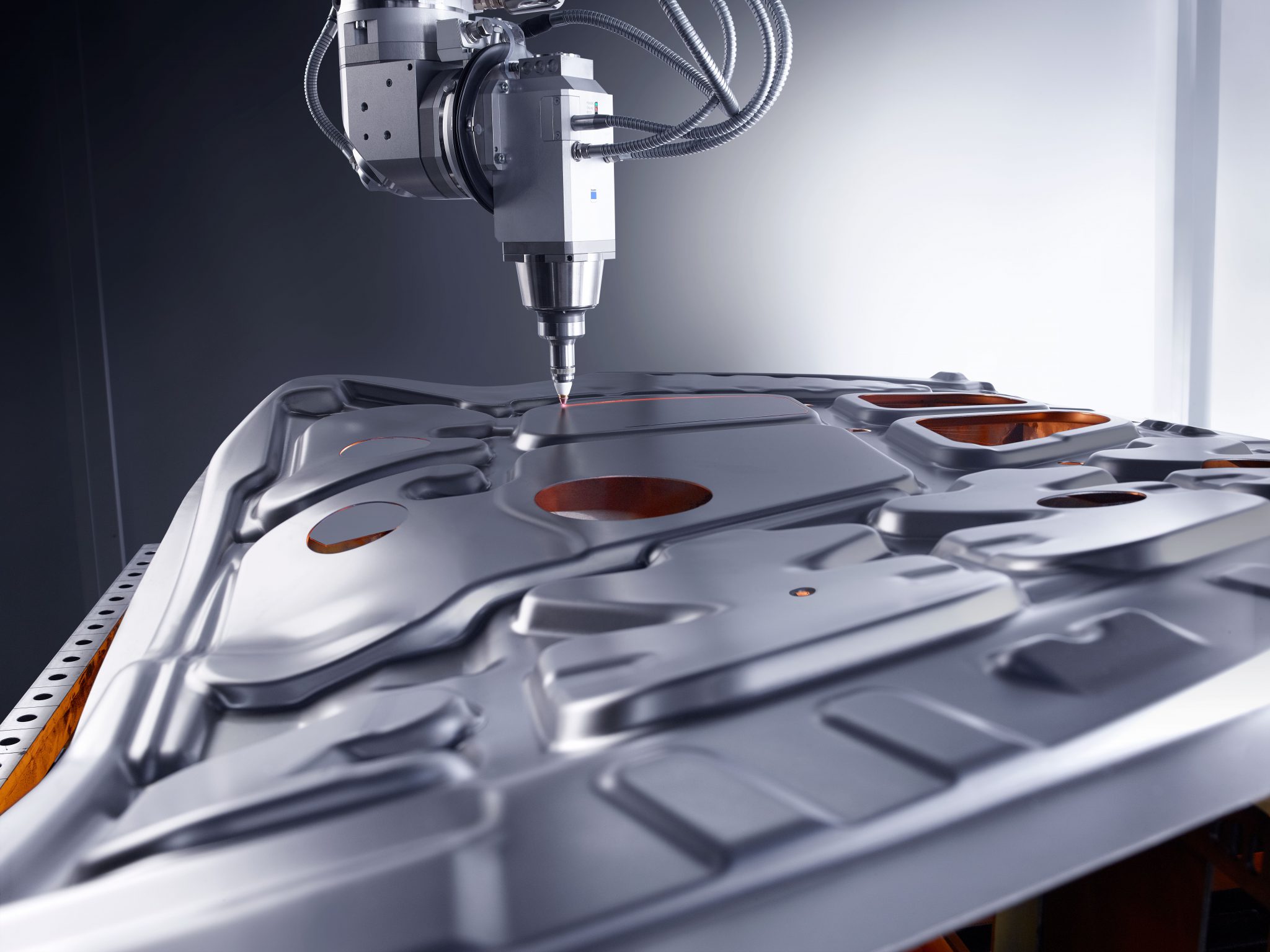

Aerospace: Precision cutting of aircraft components, engine parts, and lightweight structures.

Automotive: Fabrication of vehicle parts, interior trims, and customized designs.

3D laser cutting is a revolutionary manufacturing technique that has transformed various industries, offering unparalleled precision, speed, and design flexibility. In the United Kingdom, the demand for 3D laser cutting services has surged, catering to diverse sectors such as aerospace, automotive, healthcare, and consumer electronics. This comprehensive guide delves into the world of 3D laser cutting UK, providing a detailed overview of its capabilities, applications, and benefits.

- 3d Laser Cut Crystal Cubes 3D Laser Cut Crystal Cubes: The Ultimate Guide To Captivating Decor And Personalized Gifts

- 3d Puzzle Laser Cut Template 3D Puzzle Laser Cut Template: A Comprehensive Guide To Design, Creation, And Assembly

- 3d Puzzle Laser Cut Files 3D Puzzle Laser Cut Files: A Comprehensive Guide For Designers And Makers

- 3d Laser Cut Templates 3D Laser Cut Templates: Unleashing Creativity And Precision

- 3d Laser Crystal Engraving Machine 3D Laser Crystal Engraving Machine: Unlocking Limitless Creative Possibilities

What is 3D Laser Cutting?

3D laser cutting involves using a computer-controlled laser to cut and shape three-dimensional objects from a variety of materials, including metals, plastics, wood, and composites. The laser beam is precisely directed and focused, allowing for intricate cuts with exceptional accuracy and detail. Unlike traditional cutting methods, 3D laser cutting produces minimal waste and eliminates the need for secondary finishing operations.

Advantages of 3D Laser Cutting

Precision and Accuracy: 3D laser cutting offers unmatched precision, ensuring dimensional accuracy and intricate details. The laser’s tight beam control allows for precise cuts and complex geometries.

Speed and Efficiency: Laser cutting is a rapid process, significantly reducing production time compared to traditional methods. Automated systems and advanced software optimize the cutting process for maximum efficiency.

Healthcare: Manufacturing of medical devices, surgical instruments, and implants.

Consumer Electronics: Production of smartphones, tablets, and other electronic devices.

Architecture and Design: Creation of intricate facades, sculptures, and architectural elements.

Choosing a 3D Laser Cutting Service Provider in the UK

When selecting a 3D laser cutting service provider in the UK, consider the following factors:

Capabilities and Expertise: Ensure the provider has the necessary equipment and expertise to handle your specific requirements.

Material Compatibility: Verify that the provider can work with the materials you require.

Accuracy and Precision: Inquire about the provider’s accuracy and precision capabilities to meet your design specifications.

Speed and Efficiency: Determine the provider’s capacity and turnaround times to meet your production deadlines.

Quality Control: Ask about the provider’s quality control measures to ensure consistent and high-quality results.

Conclusion

3D laser cutting UK is a transformative manufacturing technology that empowers businesses with unparalleled precision, speed, and design flexibility. Its wide-ranging applications and environmental benefits make it a valuable asset in various industries. By carefully selecting a reputable service provider, businesses can harness the power of 3D laser cutting to drive innovation, enhance product quality, and streamline production processes.

FAQs

Q: What is the typical cost of 3D laser cutting services in the UK?

A: Costs vary depending on the complexity of the design, material used, and volume of production. Contact service providers for specific quotes.

Q: Can 3D laser cutting be used for prototyping?

A: Yes, 3D laser cutting is an excellent option for prototyping, allowing rapid production of functional prototypes with high accuracy.

Q: What materials are suitable for 3D laser cutting?

A: 3D laser cutting can handle a wide range of materials, including metals, plastics, wood, and composites. Check with service providers for specific material capabilities.

Q: How can I ensure the quality of 3D laser cut parts?

A: Look for service providers with rigorous quality control processes, including inspection and testing to ensure dimensional accuracy and surface finish.

Q: Is 3D laser cutting environmentally friendly?

A: Yes, 3D laser cutting is a relatively environmentally friendly process, as it produces minimal waste and uses less energy than traditional cutting methods.