3D Laser Cutting Acrylic: A Comprehensive Guide

Introduction

3D laser cutting acrylic is a versatile and precise manufacturing technique that enables the creation of intricate and complex three-dimensional objects from acrylic sheets. This advanced technology offers numerous advantages over traditional cutting methods, making it an ideal solution for a wide range of applications in various industries.

Table of Content

- 1 3D Laser Cutting Acrylic: A Comprehensive Guide

- 1.1 Introduction

- 1.2 What is 3D Laser Cutting Acrylic?

- 1.3 Advantages of 3D Laser Cutting Acrylic

- 1.4 Applications of 3D Laser Cutting Acrylic

- 1.5 What is 3D Laser Cutting Acrylic?

- 1.6 Advantages of 3D Laser Cutting Acrylic

- 1.7 Process of 3D Laser Cutting Acrylic

- 1.8 Factors Affecting 3D Laser Cutting Acrylic

- 1.9 Conclusion

- 1.10 Frequently Asked Questions (FAQs)

What is 3D Laser Cutting Acrylic?

Advantages of 3D Laser Cutting Acrylic

Precision and Accuracy: Laser cutting provides exceptional precision and accuracy, allowing for the creation of complex shapes and intricate designs with minimal deviation.

Speed and Efficiency: Laser cutting is a fast and efficient process, significantly reducing production time compared to traditional methods.

Non-Contact Cutting: The non-contact nature of laser cutting eliminates the need for physical tools, minimizing material deformation and ensuring a clean and polished finish.

Design Flexibility: Laser cutting enables the production of intricate and customized designs, including shapes with sharp corners, fine details, and curved surfaces.

Material Versatility: Acrylic is a versatile material that can be easily cut with a laser, allowing for the production of a wide range of objects from different colors and thicknesses.

Applications of 3D Laser Cutting Acrylic

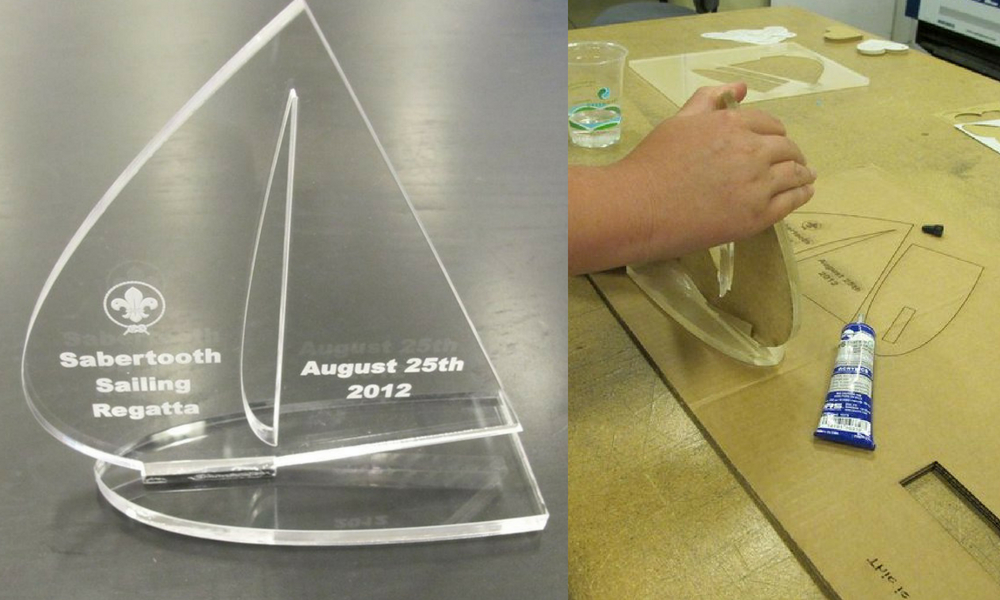

Prototyping and Product Development: Laser-cut acrylic prototypes provide a cost-effective and rapid way to evaluate designs and make necessary adjustments before mass production.

Architectural Models: Laser-cut acrylic is used to create detailed architectural models, providing precise representations of buildings and structures.

Signage and Displays: Laser-cut acrylic is ideal for creating durable and attractive signage, displays, and exhibition stands with eye-catching designs.

3D laser cutting acrylic is a versatile and precise manufacturing technique that enables the creation of intricate and complex three-dimensional objects from acrylic sheets. This advanced technology offers numerous advantages over traditional cutting methods, making it an ideal solution for a wide range of applications in various industries.

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

- 3d Laser Cut Projects 3D Laser Cut Projects: Unleashing Creativity And Innovation

- Simple 3d Laser Cut Simple 3D Laser Cut: A Comprehensive Guide

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide

- Thingiverse Laser Cut Thingiverse Laser Cut: Unleashing The Power Of Digital Fabrication

What is 3D Laser Cutting Acrylic?

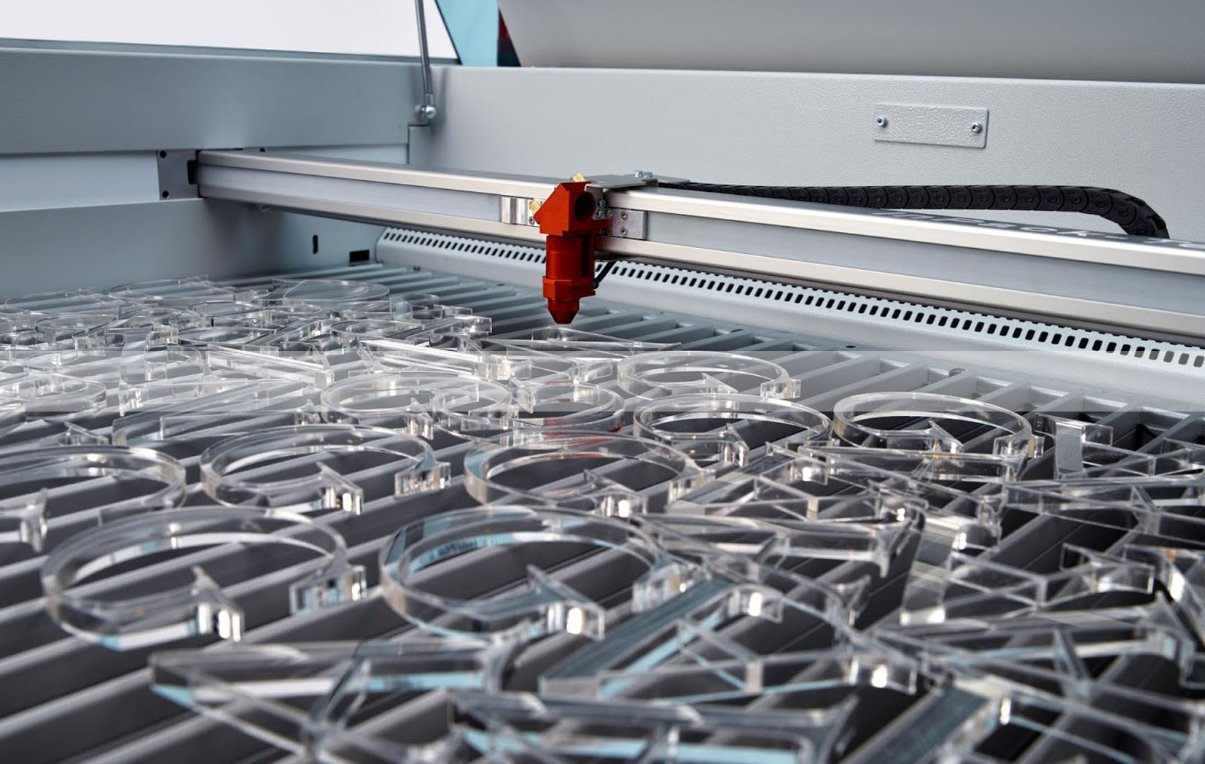

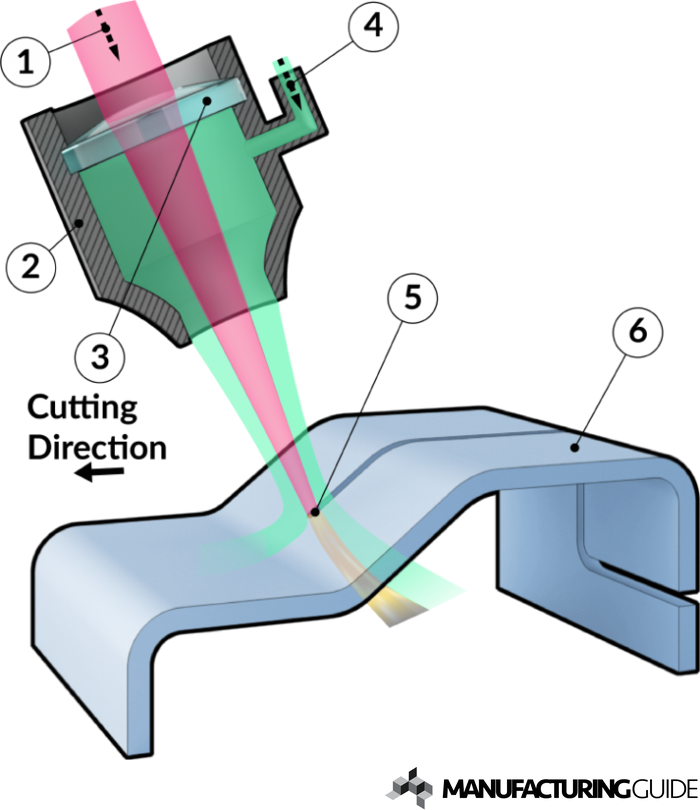

3D laser cutting acrylic involves the use of a laser beam to precisely cut and shape acrylic sheets in three dimensions. The laser beam is guided by computer-aided design (CAD) software to follow predefined paths, resulting in highly accurate and detailed cuts. The process is performed on a specialized laser cutter that controls the movement of the laser beam and the positioning of the acrylic sheet.

Advantages of 3D Laser Cutting Acrylic

Precision and Accuracy: Laser cutting provides exceptional precision and accuracy, allowing for the creation of complex shapes and intricate designs with minimal deviation.

Speed and Efficiency: Laser cutting is a fast and efficient process, significantly reducing production time compared to traditional methods.

Medical Devices: Laser-cut acrylic is utilized in the production of medical devices, such as surgical instruments, prosthetics, and medical equipment.

Consumer Products: Laser-cut acrylic finds applications in various consumer products, including toys, jewelry, home décor, and automotive parts.

Process of 3D Laser Cutting Acrylic

The process of 3D laser cutting acrylic typically involves the following steps:

- Design Creation: A 3D CAD model of the desired object is created using software.

- Material Preparation: The acrylic sheet is prepared by cleaning and ensuring it is flat and free of any imperfections.

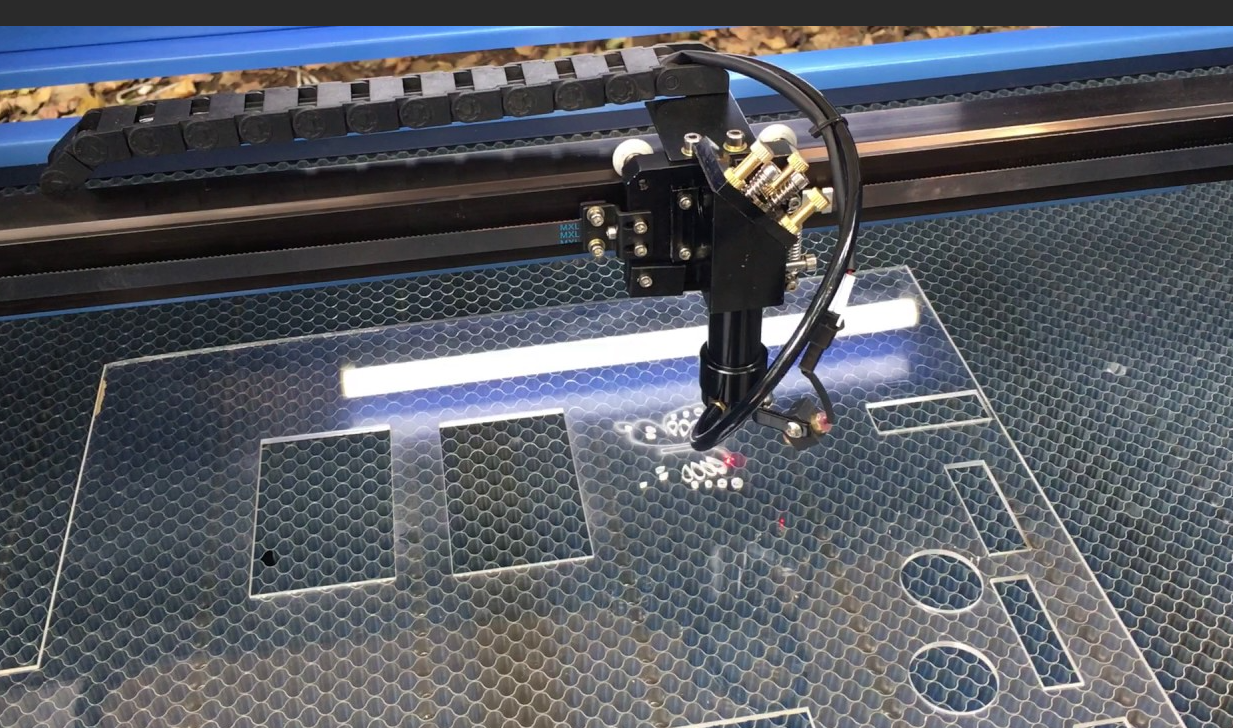

- Laser Cutting: The laser cutter is programmed with the CAD design and the acrylic sheet is placed on the cutting bed.

- Cutting and Shaping: The laser beam follows the predefined path, cutting and shaping the acrylic sheet into the desired 3D object.

- Post-Processing: The cut object is removed from the laser cutter and may undergo additional post-processing steps, such as sanding, polishing, or assembly.

Factors Affecting 3D Laser Cutting Acrylic

Several factors can influence the outcome of 3D laser cutting acrylic:

Laser Power: The power of the laser beam determines the cutting speed and depth.

Laser Wavelength: The wavelength of the laser affects the material absorption and cutting efficiency.

Cutting Speed: The speed at which the laser moves across the acrylic sheet impacts the cut quality and precision.

Material Thickness: The thickness of the acrylic sheet affects the cutting parameters and the overall production time.

Gas Assist: The use of assist gases, such as nitrogen or oxygen, can improve cut quality and reduce the risk of material melting or burning.

Conclusion

3D laser cutting acrylic is a revolutionary technology that offers numerous advantages over traditional cutting methods. Its precision, speed, and versatility make it an ideal solution for various applications in industries ranging from prototyping to consumer products. By understanding the process, factors affecting the outcome, and the wide range of applications, businesses can harness the power of 3D laser cutting to create innovative and high-quality products.

Frequently Asked Questions (FAQs)

Q: What is the maximum thickness of acrylic that can be cut with a laser?

A: The maximum thickness that can be cut depends on the laser power and wavelength. Generally, lasers with higher power and shorter wavelengths can cut thicker acrylic sheets.

Q: Can 3D laser cutting acrylic produce clear and polished edges?

A: Yes, with proper laser parameters and post-processing, 3D laser cutting can achieve clear and polished edges on acrylic sheets.

Q: Is 3D laser cutting acrylic suitable for mass production?

A: Yes, 3D laser cutting is a highly efficient and cost-effective process that can be scaled up for mass production of acrylic objects.

Q: What are the safety considerations when using a laser cutter for acrylic?

A: Laser cutting acrylic requires proper safety precautions, including the use of protective eyewear, ventilation systems, and appropriate materials handling techniques.

Q: Can 3D laser cutting acrylic be used to create hollow or enclosed objects?

A: Yes, by carefully controlling the laser parameters and using multiple passes, it is possible to create hollow or enclosed objects from acrylic sheets using 3D laser cutting.