3D Laser Cutting Services: Precision and Innovation in Fabrication

Introduction

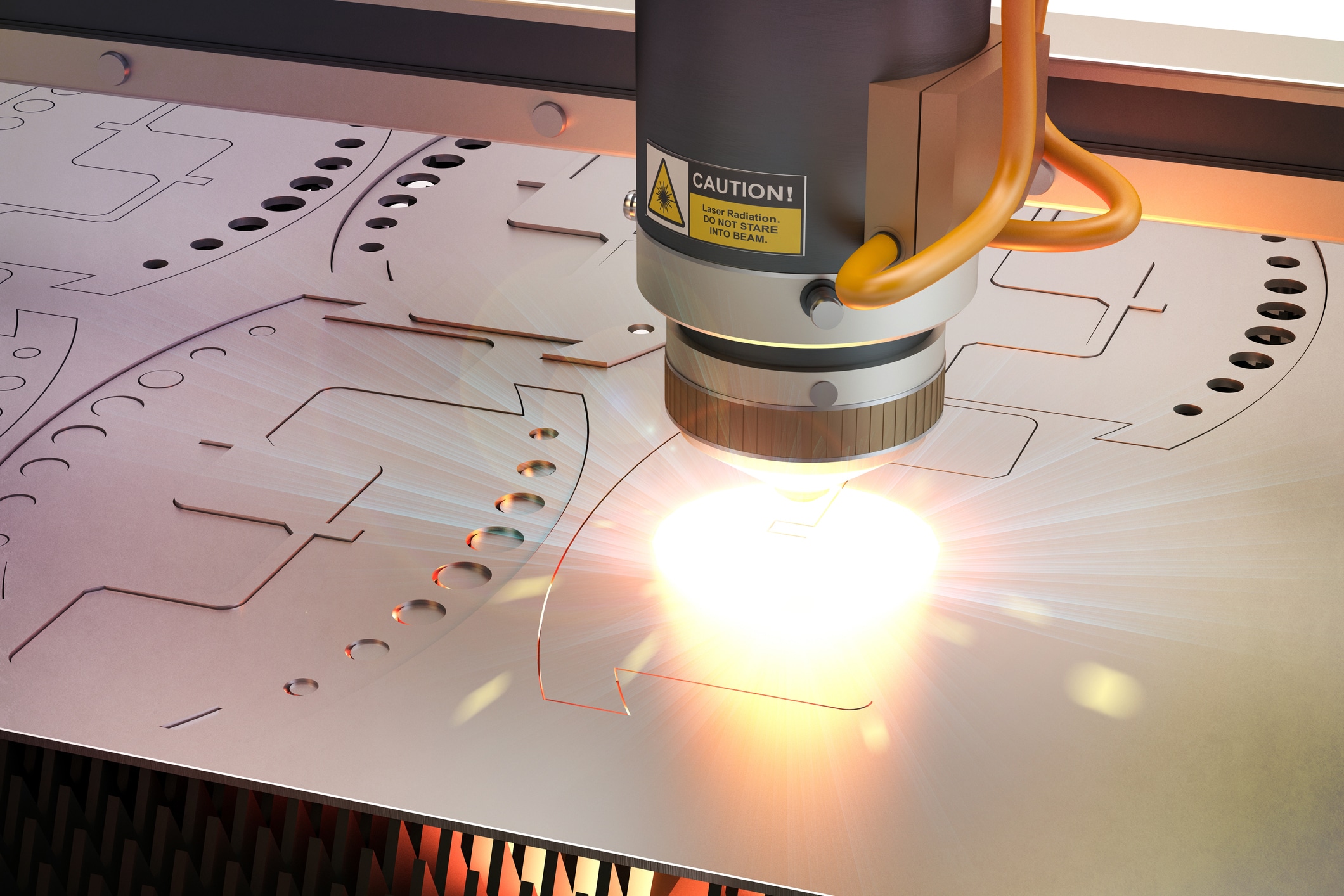

In the realm of manufacturing, precision and efficiency are paramount. 3D laser cutting services have emerged as a transformative technology that meets these demands with unparalleled accuracy and speed. By harnessing the power of lasers, these services enable the creation of complex and intricate parts with unparalleled precision and detail. This article delves into the world of 3D laser cutting services, exploring their capabilities, benefits, applications, and the factors to consider when choosing a provider.

Table of Content

- 1 3D Laser Cutting Services: Precision and Innovation in Fabrication

- 1.1 Introduction

- 1.2 H1: Capabilities of 3D Laser Cutting Services

- 1.3 H2: Benefits of 3D Laser Cutting Services

- 1.4 H1: Capabilities of 3D Laser Cutting Services

- 1.5 H3: Applications of 3D Laser Cutting Services

- 1.6 H4: Choosing a 3D Laser Cutting Service Provider

- 1.7 Conclusion

- 1.8 FAQs

H1: Capabilities of 3D Laser Cutting Services

Key Capabilities:

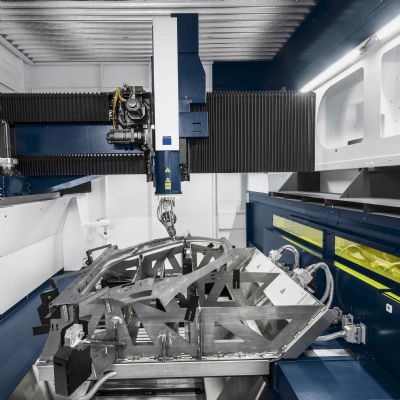

- Multi-Axis Cutting: 3D laser cutters can operate on multiple axes, enabling them to cut complex shapes from all sides, including intricate curves and angles.

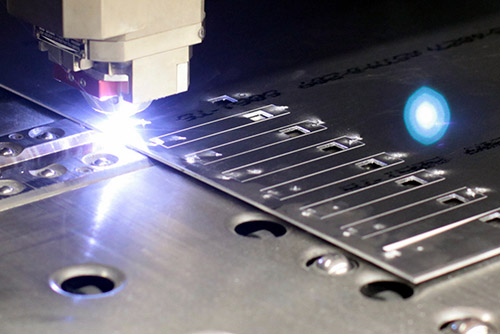

- High Precision: Lasers produce extremely fine and precise cuts, ensuring accuracy and detail in the finished product.

- Material Versatility: 3D laser cutters can cut a wide range of materials, from delicate plastics to sturdy metals, providing versatility in manufacturing.

- Speed and Efficiency: Laser cutting processes are highly efficient, reducing production time and minimizing material waste.

H2: Benefits of 3D Laser Cutting Services

3D laser cutting services offer numerous benefits to businesses and manufacturers, including:

- 3d Laser Cut Toy 3D Laser Cut Toys: A Revolution In The Toy Industry

- 3d Puzzle Laser Cut Files 3D Puzzle Laser Cut Files: A Comprehensive Guide For Designers And Makers

- Laser Cut 3d Puzzle Free Download Laser Cut 3D Puzzle: Free Download And Assembly Guide

- 3d Laser Cut Cards 3D Laser Cut Cards: A Guide To Enchanting And Intricate Paper Art

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide

- Multi-Axis Cutting: 3D laser cutters can operate on multiple axes, enabling them to cut complex shapes from all sides, including intricate curves and angles.

- Increased Precision: Laser cutting eliminates human error and ensures consistent accuracy, reducing the risk of defects and rework.

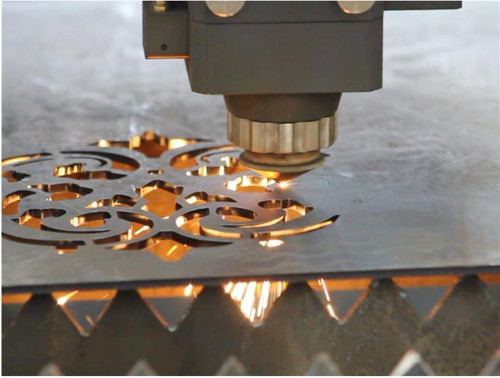

- Enhanced Design Flexibility: The ability to cut intricate shapes and angles allows for the creation of innovative and complex designs.

- Reduced Material Waste: Laser cutting’s precise cuts minimize material waste, resulting in cost savings and environmental sustainability.

- Faster Production Time: The speed and efficiency of laser cutting processes reduce production lead times, enabling faster delivery of products.

- Improved Surface Quality: Laser cutting creates smooth and clean surfaces, eliminating the need for additional finishing processes.

- Aerospace: Manufacturing of aircraft components, engine parts, and other critical structures.

- Automotive: Production of automotive parts, trim, and interior components.

- Medical: Fabrication of surgical instruments, prosthetics, and medical implants.

- Electronics: Cutting of PCBs, circuit boards, and electronic components.

- Jewelry: Creation of intricate jewelry designs, pendants, and earrings.

- Architecture: Production of architectural models, scale replicas, and building components.

- Experience and Expertise: Choose a provider with a proven track record and expertise in the specific materials and applications you require.

- Equipment and Technology: Ensure the provider has advanced laser cutting equipment and software to meet your precision and speed requirements.

- Quality Control: Inquire about the provider’s quality control processes and certifications to ensure adherence to industry standards.

- Customer Service: Consider the provider’s responsiveness, communication skills, and ability to provide technical support when needed.

- Cost and Value: Evaluate the provider’s pricing structure and compare it to the quality and value of their services.

In the realm of manufacturing, precision and efficiency are paramount. 3D laser cutting services have emerged as a transformative technology that meets these demands with unparalleled accuracy and speed. By harnessing the power of lasers, these services enable the creation of complex and intricate parts with unparalleled precision and detail. This article delves into the world of 3D laser cutting services, exploring their capabilities, benefits, applications, and the factors to consider when choosing a provider.

H1: Capabilities of 3D Laser Cutting Services

3D laser cutting services utilize high-powered lasers to cut and shape a wide range of materials, including metals, plastics, wood, and composites. The laser beam is precisely controlled, allowing for the creation of intricate designs and precise cuts with minimal material waste.

Key Capabilities:

H3: Applications of 3D Laser Cutting Services

3D laser cutting services find application in a diverse range of industries, including:

H4: Choosing a 3D Laser Cutting Service Provider

Selecting the right 3D laser cutting service provider is crucial for ensuring quality and efficiency. Key factors to consider include:

Conclusion

3D laser cutting services are revolutionizing manufacturing processes with their unparalleled precision, speed, and versatility. By harnessing the power of lasers, these services enable the creation of intricate and complex parts with minimal material waste and reduced production time. Choosing the right provider is essential for ensuring quality and efficiency, allowing businesses to unlock the full potential of 3D laser cutting technology.

FAQs

Q: What materials can be cut with 3D laser cutting services?

A: Metals, plastics, wood, composites, and other materials.

Q: Is 3D laser cutting more expensive than traditional cutting methods?

A: In some cases, laser cutting may be more expensive upfront, but it often leads to cost savings in the long run due to reduced material waste and faster production time.

Q: How accurate is 3D laser cutting?

A: Laser cutting provides extremely high precision, with tolerances as fine as a few microns.

Q: Can 3D laser cutting be used for large-scale projects?

A: Yes, laser cutting systems can accommodate large workpieces and can be used for mass production.

Q: What is the future of 3D laser cutting technology?

A: The future of 3D laser cutting involves advancements in laser technology, automation, and software, leading to even greater precision, speed, and versatility.