3D Laser Cutting Melbourne: The Ultimate Guide to Precision and Efficiency

Introduction

In the realm of manufacturing, precision and efficiency reign supreme. 3D laser cutting in Melbourne has emerged as a revolutionary technology that seamlessly marries these two essential elements, transforming the way industries operate and innovate. This comprehensive guide delves into the intricate world of 3D laser cutting, exploring its capabilities, benefits, applications, and the leading providers in Melbourne.

Table of Content

- 1 3D Laser Cutting Melbourne: The Ultimate Guide to Precision and Efficiency

- 1.1 Introduction

- 2 What is 3D Laser Cutting?

- 3 How Does 3D Laser Cutting Work?

- 4 Advantages of 3D Laser Cutting

- 5 What is 3D Laser Cutting?

- 6 How Does 3D Laser Cutting Work?

- 7 Advantages of 3D Laser Cutting

- 8 Applications of 3D Laser Cutting

- 9 Leading 3D Laser Cutting Providers in Melbourne

- 10 Conclusion

- 11 FAQs

What is 3D Laser Cutting?

How Does 3D Laser Cutting Work?

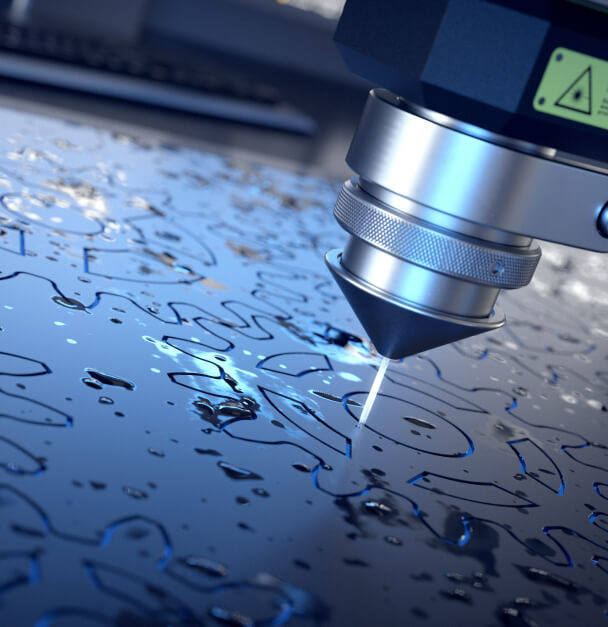

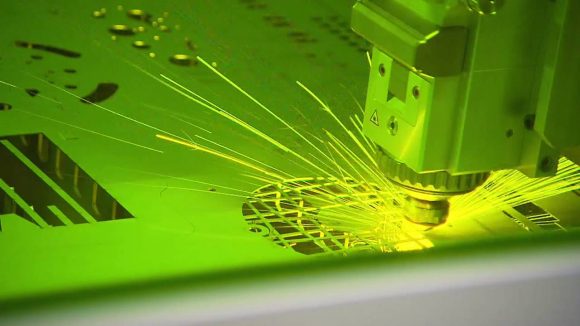

3D laser cutting systems employ a high-powered laser beam that is precisely guided by a computer-aided design (CAD) file. The laser beam is focused onto the workpiece, generating intense heat that vaporizes or melts the material, creating a clean and precise cut. The cutting head moves along the predefined path, meticulously following the contours of the desired shape.

Advantages of 3D Laser Cutting

3D laser cutting offers a myriad of advantages over traditional manufacturing methods:

- Precision: The laser beam’s pinpoint accuracy ensures exceptional precision, allowing for the creation of intricate designs with tight tolerances.

- Speed and Efficiency: Laser cutting is a remarkably fast process, resulting in increased production rates and reduced lead times.

- Versatility: 3D laser cutting can process a wide range of materials, including metals, plastics, wood, and composites.

- Complex Geometries: Laser cutting enables the production of complex shapes and intricate features that would be challenging or impossible to achieve with other methods.

- Reduced Material Waste: Laser cutting minimizes material waste, as it only removes the necessary material from the workpiece.

- 3d Laser Cut Wood Models 3D Laser Cut Wood Models: An Intricate And Enchanting World Of Precision And Creativity

- 3d Laser Cut Lake Maps 3D Laser Cut Lake Maps: A Comprehensive Guide To Precision Mapping

- 3d Laser Cutter Printer 3D Laser Cutter Printer: A Comprehensive Guide To Advanced Fabrication Technology

- Laser Cut 3d Pop Cards Laser Cut 3D Pop Cards: A Captivating Expression Of Creativity And Emotion

- 3d Printing And Laser Cutting 3D Printing And Laser Cutting: A Comprehensive Guide

- Non-Contact Process: The laser beam does not physically touch the workpiece, eliminating the risk of deformation or damage.

In the realm of manufacturing, precision and efficiency reign supreme. 3D laser cutting in Melbourne has emerged as a revolutionary technology that seamlessly marries these two essential elements, transforming the way industries operate and innovate. This comprehensive guide delves into the intricate world of 3D laser cutting, exploring its capabilities, benefits, applications, and the leading providers in Melbourne.

What is 3D Laser Cutting?

3D laser cutting, also known as 3D laser profiling, is an advanced manufacturing process that utilizes a laser beam to cut intricate shapes and designs into three-dimensional materials. Unlike traditional laser cutting, which operates on flat surfaces, 3D laser cutting enables the precise cutting of complex geometries and curved surfaces.

How Does 3D Laser Cutting Work?

3D laser cutting systems employ a high-powered laser beam that is precisely guided by a computer-aided design (CAD) file. The laser beam is focused onto the workpiece, generating intense heat that vaporizes or melts the material, creating a clean and precise cut. The cutting head moves along the predefined path, meticulously following the contours of the desired shape.

Advantages of 3D Laser Cutting

Applications of 3D Laser Cutting

3D laser cutting has found widespread application across various industries:

- Automotive: Prototyping, interior trim, and exhaust systems

- Aerospace: Structural components, engine parts, and aircraft interiors

- Medical: Surgical instruments, implants, and prosthetics

- Architecture: Decorative elements, building facades, and architectural models

- Consumer Products: Jewelry, eyewear, and electronics

- Industrial Machinery: Components, gears, and enclosures

Leading 3D Laser Cutting Providers in Melbourne

Melbourne boasts several reputable providers of 3D laser cutting services:

- Rapid Prototyping Technologies: A leading provider of 3D printing and laser cutting services, specializing in rapid prototyping and low-volume production.

- Laser Melbourne: A well-established laser cutting company offering a wide range of services, including 3D laser cutting, metal cutting, and engraving.

- Laser Cutting Australia: A highly experienced provider of laser cutting services, catering to a diverse range of industries.

- Multicam Australia: A global leader in laser cutting and CNC machining, offering advanced 3D laser cutting capabilities.

Conclusion

3D laser cutting in Melbourne has revolutionized the manufacturing landscape, enabling industries to achieve unparalleled precision, efficiency, and innovation. Its versatility and ability to process complex geometries have made it an indispensable tool for a wide range of applications. By partnering with reputable 3D laser cutting providers in Melbourne, businesses can harness the transformative power of this technology and unlock new possibilities for their products and processes.

FAQs

Q: What materials can be 3D laser cut?

A: 3D laser cutting can process a wide range of materials, including metals (e.g., stainless steel, aluminum, titanium), plastics (e.g., acrylic, polycarbonate, ABS), wood, and composites.

Q: What is the difference between 3D laser cutting and traditional laser cutting?

A: Traditional laser cutting operates on flat surfaces, while 3D laser cutting enables the cutting of complex geometries and curved surfaces.

Q: Is 3D laser cutting suitable for prototyping?

A: Yes, 3D laser cutting is ideal for prototyping as it allows for the rapid and precise creation of complex shapes and designs.

Q: What are the benefits of using 3D laser cutting?

A: 3D laser cutting offers numerous benefits, including precision, speed, versatility, reduced material waste, and non-contact processing.

Q: How do I choose a reputable 3D laser cutting provider?

A: When choosing a 3D laser cutting provider, consider their experience, capabilities, turnaround time, and customer support.