3D Laser Cutting Head: Revolutionizing Precision Cutting

Introduction

In the realm of laser cutting, the advent of 3D laser cutting heads has brought unprecedented capabilities and precision. These advanced cutting systems have revolutionized the manufacturing industry, enabling intricate and complex cutting applications on a wide range of materials.

Table of Content

- 1 3D Laser Cutting Head: Revolutionizing Precision Cutting

- 1.1 Introduction

- 1.2 H1: Understanding 3D Laser Cutting Heads

- 1.3 H2: Key Components of a 3D Laser Cutting Head

- 1.4 H3: Advantages of 3D Laser Cutting

- 1.5 H1: Understanding 3D Laser Cutting Heads

- 1.6 H2: Key Components of a 3D Laser Cutting Head

- 1.7 H4: Applications of 3D Laser Cutting

- 1.8 H5: Factors to Consider When Selecting a 3D Laser Cutting Head

- 1.9 H6: Conclusion

- 1.10 FAQs

H1: Understanding 3D Laser Cutting Heads

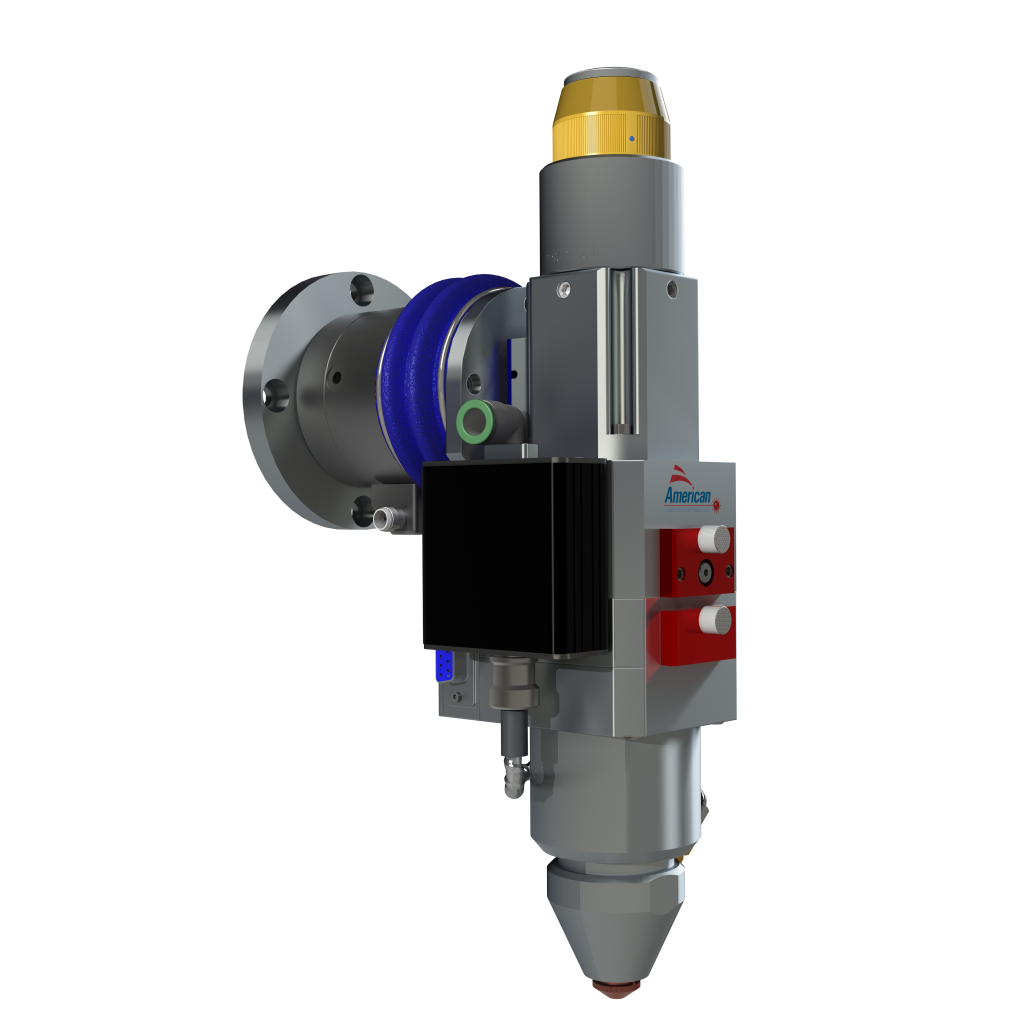

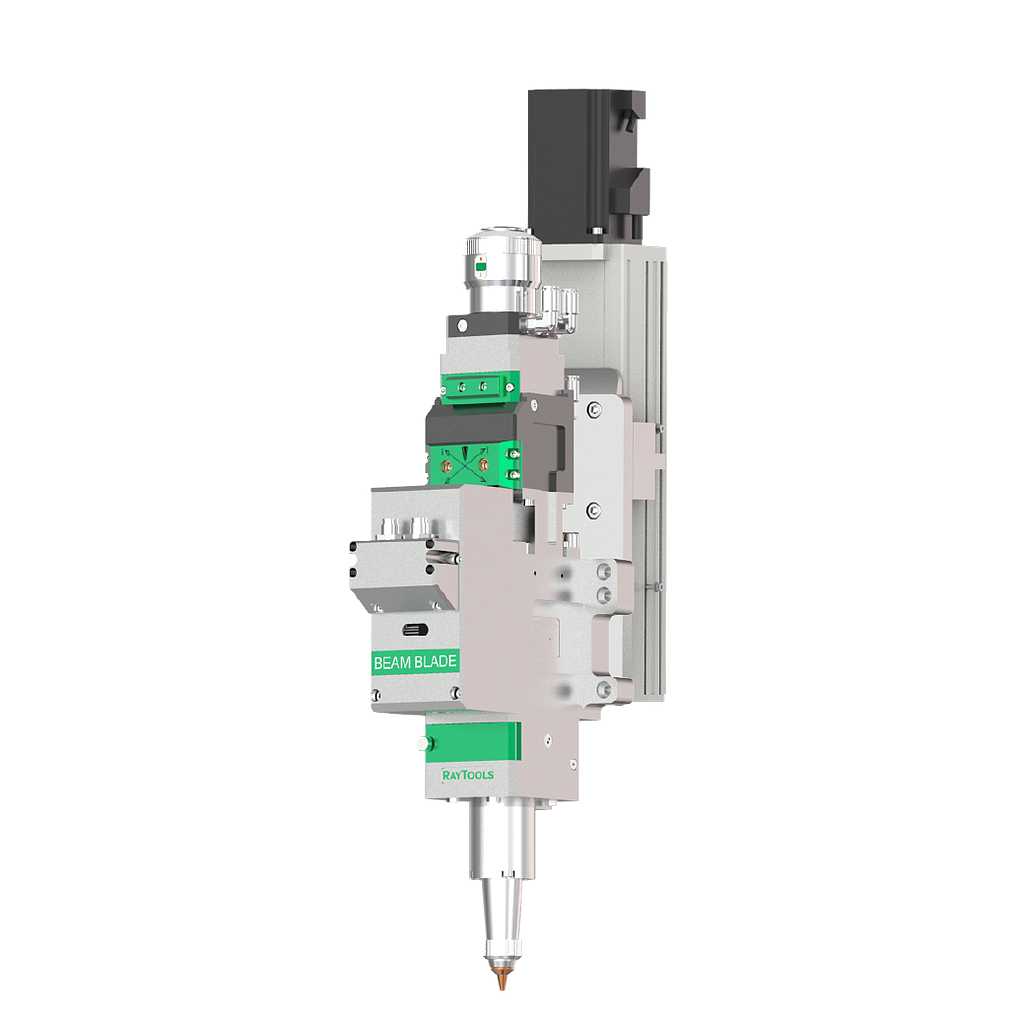

H2: Key Components of a 3D Laser Cutting Head

1. Laser Source: The heart of the 3D laser cutting head is the laser source, which generates a high-power laser beam. Common laser sources include CO2, fiber, and diode lasers.

2. Focusing Optics: The laser beam is focused onto the workpiece using a series of lenses and mirrors. This ensures a precise and narrow cutting path.

3. Beam Delivery System: The beam delivery system consists of mirrors and optical fibers that guide the laser beam from the source to the cutting head.

4. Cutting Head Body: The cutting head body houses the focusing optics and other components. It is designed to withstand the heat and debris generated during the cutting process.

5. Z-Axis Drive: The Z-axis drive allows the cutting head to move up and down, enabling cutting on uneven surfaces and creating complex shapes.

H3: Advantages of 3D Laser Cutting

1. Precision and Accuracy: 3D laser cutting heads offer unmatched precision and accuracy, allowing for the creation of intricate and detailed parts.

2. Versatility: These heads can cut a wide range of materials, including metals, plastics, wood, and ceramics, making them ideal for various applications.

3. High Cutting Speed: 3D laser cutting heads operate at high speeds, maximizing productivity and reducing production time.

In the realm of laser cutting, the advent of 3D laser cutting heads has brought unprecedented capabilities and precision. These advanced cutting systems have revolutionized the manufacturing industry, enabling intricate and complex cutting applications on a wide range of materials.

- 3d Laser Cut Maps 3D Laser Cut Maps: Unraveling The World’s Topography

- 3d Laser Cut Signs 3D Laser Cut Signs: The Ultimate Guide To Captivating And Durable Signage

- 3d Laser Cut Fish 3D Laser Cut Fish: A Comprehensive Guide

- Free 3d Laser Cut Designs Free 3D Laser Cut Designs: Unleashing Creativity And Precision

- Laser Cut 3d Maze Laser Cut 3D Maze: A Labyrinth Of Intricate Design

H1: Understanding 3D Laser Cutting Heads

3D laser cutting heads are sophisticated devices that employ a focused laser beam to cut through materials in three dimensions. Unlike traditional 2D laser cutting heads, which only move in the X and Y axes, 3D heads have the added capability of moving in the Z axis, allowing them to cut on uneven surfaces and create complex shapes.

H2: Key Components of a 3D Laser Cutting Head

1. Laser Source: The heart of the 3D laser cutting head is the laser source, which generates a high-power laser beam. Common laser sources include CO2, fiber, and diode lasers.

2. Focusing Optics: The laser beam is focused onto the workpiece using a series of lenses and mirrors. This ensures a precise and narrow cutting path.

4. Reduced Material Waste: The precise cutting process minimizes material waste, leading to cost savings and improved sustainability.

5. Automation Compatibility: 3D laser cutting heads are easily integrated into automated systems, enabling efficient and consistent cutting operations.

H4: Applications of 3D Laser Cutting

1. Aerospace: Cutting complex shapes for aircraft components, such as engine parts and wing structures.

2. Automotive: Producing intricate parts for vehicles, such as dashboards, seats, and engine components.

3. Medical: Fabricating medical devices, such as surgical instruments, implants, and prosthetics.

4. Electronics: Cutting printed circuit boards (PCBs) and other electronic components with high precision.

5. Jewelry: Creating intricate and detailed jewelry pieces, including rings, necklaces, and bracelets.

H5: Factors to Consider When Selecting a 3D Laser Cutting Head

1. Laser Power: The laser power determines the cutting speed and thickness of materials that can be cut.

2. Beam Quality: The beam quality affects the precision and accuracy of the cutting process.

3. Cutting Speed: The cutting speed is crucial for maximizing productivity.

4. Material Compatibility: Ensure that the cutting head is compatible with the materials you intend to cut.

5. Automation Compatibility: Consider the compatibility of the cutting head with your automated systems.

H6: Conclusion

3D laser cutting heads have revolutionized the manufacturing industry, offering unparalleled precision, versatility, and efficiency. Their ability to cut complex shapes on uneven surfaces has opened up new possibilities for innovation and creativity. As technology continues to advance, we can expect further advancements in 3D laser cutting technology, further transforming the way we manufacture products.

FAQs

1. What is the difference between 2D and 3D laser cutting heads?

3D laser cutting heads have the added capability of moving in the Z axis, enabling cutting on uneven surfaces and creating complex shapes.

2. What materials can be cut with a 3D laser cutting head?

3D laser cutting heads can cut a wide range of materials, including metals, plastics, wood, and ceramics.

3. What factors should be considered when selecting a 3D laser cutting head?

Laser power, beam quality, cutting speed, material compatibility, and automation compatibility are important factors to consider.

4. What are the advantages of 3D laser cutting?

Precision, accuracy, versatility, high cutting speed, reduced material waste, and automation compatibility are key advantages.

5. What applications can benefit from 3D laser cutting?

Aerospace, automotive, medical, electronics, and jewelry industries all utilize 3D laser cutting for intricate and complex cutting tasks.