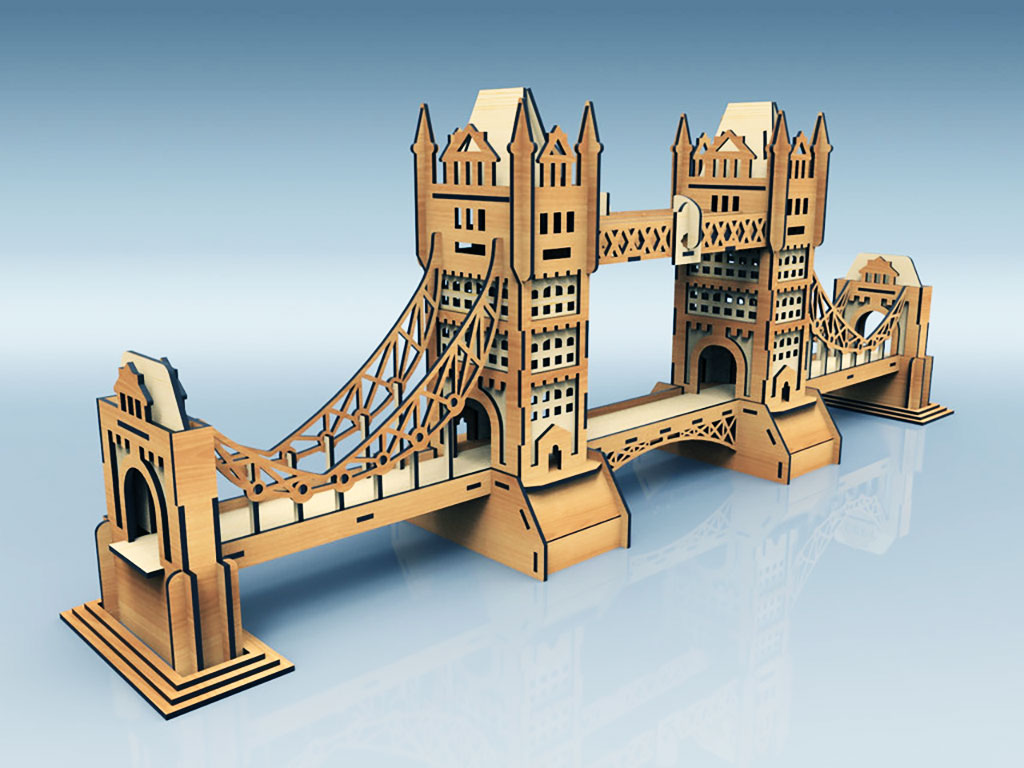

3D Laser Cutting Designs: Transforming Flat Surfaces into Dimensional Masterpieces

Introduction

3D laser cutting technology has revolutionized the realm of design, empowering creators with the ability to transform flat surfaces into intricate and captivating three-dimensional masterpieces. By harnessing the precision and power of lasers, designers can now explore new dimensions of creativity, unlocking a world of possibilities for various industries.

Table of Content

- 1 3D Laser Cutting Designs: Transforming Flat Surfaces into Dimensional Masterpieces

- 1.1 Introduction

- 1.2 What is 3D Laser Cutting?

- 1.3 Materials for 3D Laser Cutting

- 1.4 Advantages of 3D Laser Cutting

- 1.5 What is 3D Laser Cutting?

- 1.6 Materials for 3D Laser Cutting

- 1.7 Applications of 3D Laser Cutting

- 1.8 Design Considerations for 3D Laser Cutting

- 1.9 Conclusion

- 1.10 FAQs

What is 3D Laser Cutting?

Materials for 3D Laser Cutting

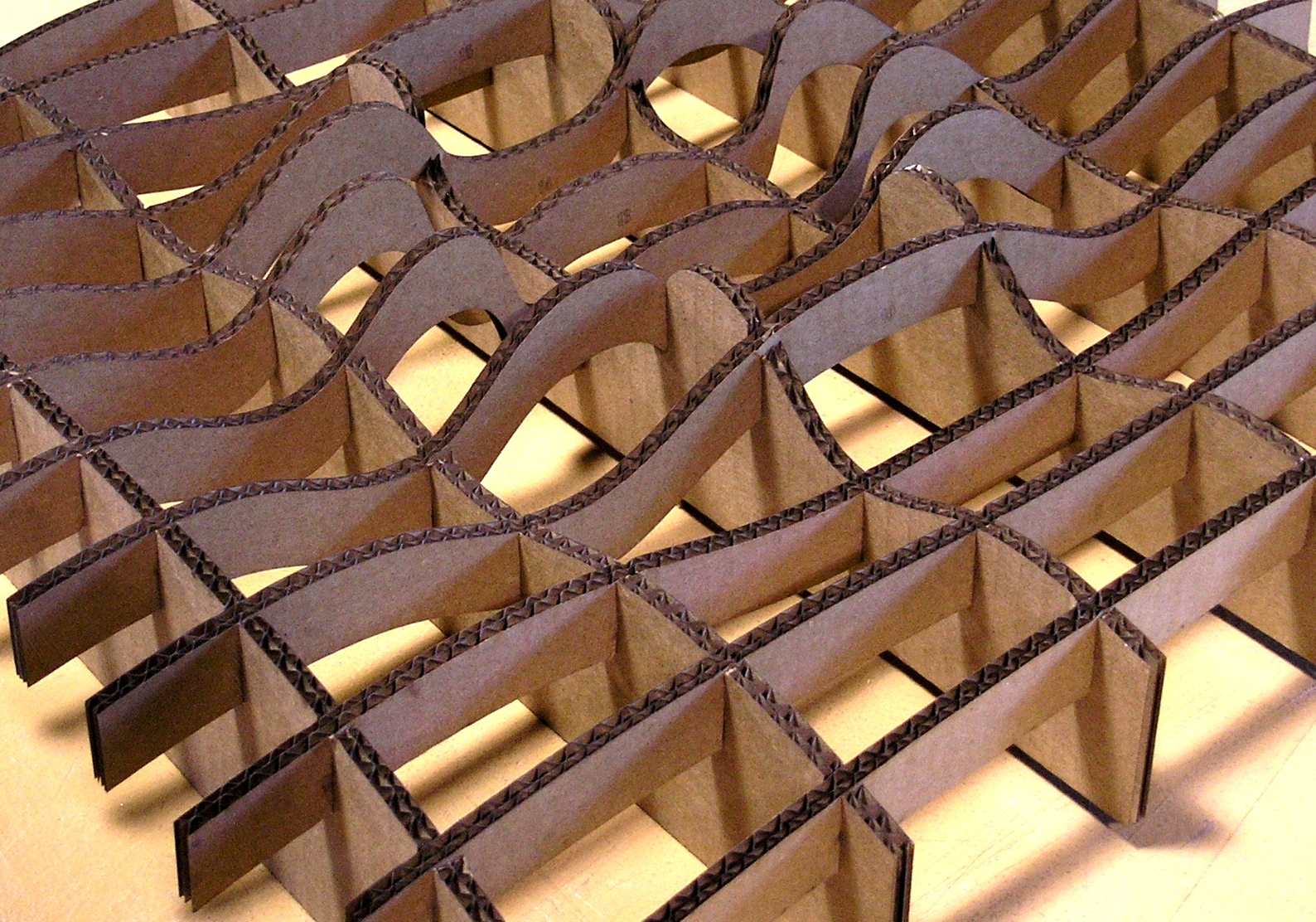

A wide range of materials can be used for 3D laser cutting, including:

- Wood: Suitable for creating intricate carvings, furniture, and decorative pieces.

- Acrylic: Ideal for transparent or translucent designs, such as lighting fixtures and signage.

- Metal: Can be cut and engraved with high precision, creating durable and robust components.

- Leather: Enables the creation of personalized accessories, wallets, and other leather goods.

- Paper and Cardstock: Perfect for intricate paper sculptures, greeting cards, and packaging designs.

Advantages of 3D Laser Cutting

3D laser cutting technology has revolutionized the realm of design, empowering creators with the ability to transform flat surfaces into intricate and captivating three-dimensional masterpieces. By harnessing the precision and power of lasers, designers can now explore new dimensions of creativity, unlocking a world of possibilities for various industries.

- 3d Laser Cut Models Download 3D Laser Cut Models Download: A Comprehensive Guide

- Laser Cut 3d Angel Laser Cut 3D Angel: A Celestial Masterpiece For Home Decor And Gift Giving

- 3d Puzzle Laser Cut Files 3D Puzzle Laser Cut Files: A Comprehensive Guide For Designers And Makers

- 3d Laser Cutting Machine 3D Laser Cutting Machine: A Comprehensive Guide

- Laser Cut 3d Model Files Laser Cut 3D Model Files: A Comprehensive Guide

What is 3D Laser Cutting?

3D laser cutting is an advanced manufacturing process that utilizes computer-controlled lasers to cut and engrave materials along multiple axes, creating complex three-dimensional shapes. The laser beam is precisely directed and focused, allowing for precise and intricate cuts, even in delicate and fragile materials.

Materials for 3D Laser Cutting

A wide range of materials can be used for 3D laser cutting, including:

- Precision and Accuracy: Lasers provide unparalleled precision, ensuring sharp and clean cuts with minimal distortion.

- Versatility: 3D laser cutting can be used on a wide range of materials, allowing for diverse design applications.

- Speed and Efficiency: Laser cutting is a rapid process, significantly reducing production time compared to manual methods.

- Customization: Designers can create highly customized and personalized designs, meeting specific customer requirements.

- Cost-Effectiveness: 3D laser cutting eliminates the need for molds or tooling, resulting in cost savings for low-volume production.

- Architecture and Interior Design: Creating decorative panels, lighting fixtures, and unique architectural elements.

- Automotive: Manufacturing custom parts, dashboards, and interior components.

- Fashion and Accessories: Designing personalized jewelry, handbags, and wearable accessories.

- Medical and Healthcare: Producing surgical instruments, prosthetics, and medical devices.

- Product Design: Developing innovative consumer products, such as electronics, appliances, and toys.

- Material Selection: Choose materials that are compatible with laser cutting and meet the desired properties.

- Design Complexity: The complexity of the design will influence the cutting time and precision required.

- File Format: Ensure the design file is in a compatible format for the laser cutting machine.

- Laser Parameters: Adjust laser power, speed, and focus to achieve the desired cut quality and depth.

- Post-Processing: Consider any necessary post-processing steps, such as sanding or polishing, to enhance the final product.

3D laser cutting offers numerous advantages over traditional manufacturing methods:

Applications of 3D Laser Cutting

The applications of 3D laser cutting extend across various industries:

Design Considerations for 3D Laser Cutting

To achieve optimal results with 3D laser cutting, consider the following design factors:

Conclusion

3D laser cutting technology has revolutionized the design industry, empowering creators to push the boundaries of creativity. By harnessing the precision and versatility of lasers, designers can transform flat surfaces into stunning three-dimensional masterpieces. As the technology continues to advance, we can expect even more innovative and captivating designs to emerge, transforming our physical world into a realm of artistic expression.

FAQs

1. What is the difference between 3D laser cutting and 2D laser cutting?

3D laser cutting involves cutting and engraving materials along multiple axes, creating three-dimensional shapes, while 2D laser cutting is limited to cutting and engraving on a flat surface.

2. Can 3D laser cutting be used on metal?

Yes, 3D laser cutting can be used on metal, allowing for the creation of durable and robust components.

3. What is the cost of 3D laser cutting?

The cost of 3D laser cutting varies depending on factors such as the material, design complexity, and production volume.

4. How can I learn more about 3D laser cutting?

There are various resources available online, including tutorials, workshops, and online courses, that can provide guidance on 3D laser cutting.

5. What are the future trends in 3D laser cutting?

The future of 3D laser cutting holds advancements in automation, precision, and material compatibility, expanding its applications in various industries.