3D Laser Cutting Machine: Revolutionizing Fabrication

Introduction

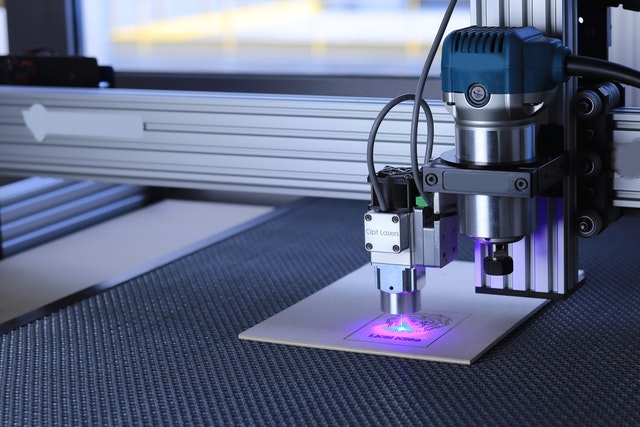

The advent of 3D laser cutting technology has revolutionized the manufacturing industry, enabling the creation of complex and precise designs with unprecedented speed and accuracy. 3D laser cutting machines empower businesses to produce a wide range of products, from intricate medical devices to high-performance automotive components.

Table of Content

Benefits of 3D Laser Cutting

3D laser cutting machines utilize advanced optics and computer-controlled systems to achieve exceptional precision and accuracy. This enables the production of intricate designs with tolerances of up to 0.005 inches.

2. Versatility:

These machines are capable of cutting a wide variety of materials, including metals, plastics, wood, and composites. This versatility allows businesses to produce diverse products in-house, eliminating the need for outsourcing.

3. Speed and Efficiency:

3D laser cutting machines operate at high speeds, significantly reducing production time. The automated nature of the process minimizes human error and increases efficiency.

4. Cost Savings:

The speed and accuracy of 3D laser cutting reduce labor costs and material waste, leading to significant savings over traditional manufacturing methods.

Applications of 3D Laser Cutting

1. Aerospace:

3D laser cutting is used to create lightweight and durable aircraft components, such as turbine blades and fuselage panels.

The advent of 3D laser cutting technology has revolutionized the manufacturing industry, enabling the creation of complex and precise designs with unprecedented speed and accuracy. 3D laser cutting machines empower businesses to produce a wide range of products, from intricate medical devices to high-performance automotive components.

- 3d Laser Cut Model 3D Laser Cut Models: A Comprehensive Guide

- 3d Puzzle Laser Cut Free 3D Puzzle Laser Cut: Unleashing Creativity And Precision

- Mazak 3d Laser Cutting Mazak 3D Laser Cutting: Revolutionizing Metal Fabrication

- Laser Cut 3d Model House Laser Cut 3D Model House: Precision Crafting And Architectural Innovation

- 3d Printers And Laser Cutters 3D Printers And Laser Cutters: A Comprehensive Guide

Benefits of 3D Laser Cutting

1. Precision and Accuracy:

3D laser cutting machines utilize advanced optics and computer-controlled systems to achieve exceptional precision and accuracy. This enables the production of intricate designs with tolerances of up to 0.005 inches.

2. Versatility:

These machines are capable of cutting a wide variety of materials, including metals, plastics, wood, and composites. This versatility allows businesses to produce diverse products in-house, eliminating the need for outsourcing.

2. Automotive:

The automotive industry utilizes 3D laser cutting for the production of intricate engine parts, body panels, and exhaust systems.

3. Medical:

This technology is essential in the fabrication of medical devices, including surgical instruments, implants, and prosthetics.

4. Electronics:

3D laser cutting machines are used to create precise circuit boards, connectors, and other electronic components.

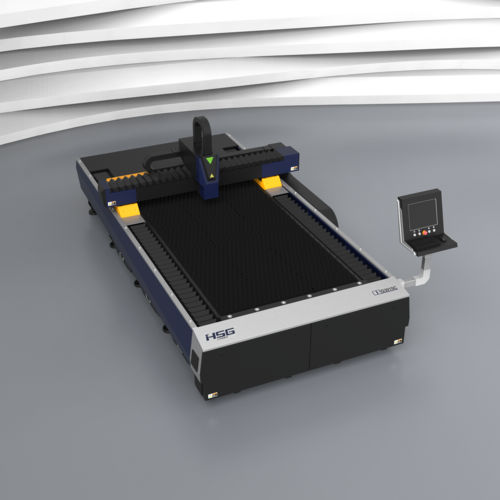

Choosing the Right 3D Laser Cutting Machine

1. Material Compatibility:

Ensure that the machine is compatible with the materials you intend to cut.

2. Cutting Speed and Accuracy:

Consider the speed and accuracy requirements of your projects.

3. Software Compatibility:

Choose a machine that is compatible with your design software to streamline the workflow.

4. Service and Support:

Reliable service and support are crucial for minimizing downtime and ensuring optimal performance.

Conclusion

3D laser cutting machines have emerged as a transformative technology in the manufacturing industry. Their precision, versatility, speed, and cost savings offer significant advantages over traditional methods. By leveraging these machines, businesses can enhance their competitiveness, innovate new products, and meet the demands of the ever-evolving market.

FAQs

1. What materials can be cut with a 3D laser cutting machine?

- Metals (e.g., steel, aluminum, titanium)

- Plastics (e.g., acrylic, polycarbonate, ABS)

- Wood

- Composites

2. How accurate are 3D laser cutting machines?

- Tolerances of up to 0.005 inches can be achieved.

3. How fast can 3D laser cutting machines operate?

- Cutting speeds vary depending on the material and thickness, but can reach up to several hundred inches per minute.

4. What is the cost of a 3D laser cutting machine?

- Prices vary depending on the size, features, and brand, but typically range from $50,000 to $500,000.

5. What are the benefits of using a 3D laser cutting machine?

- Precision and accuracy

- Versatility

- Speed and efficiency

- Cost savings