3D CNC Laser Cutting Machine: Precision Cutting for Complex Geometries

Introduction

In the realm of advanced manufacturing, 3D CNC laser cutting machines are revolutionizing the production of intricate and complex parts. By combining the precision of CNC technology with the versatility of laser cutting, these machines offer unparalleled capabilities for cutting a wide range of materials with exceptional accuracy and speed.

Table of Content

- 1 3D CNC Laser Cutting Machine: Precision Cutting for Complex Geometries

- 1.1 Introduction

- 1.2 H1: Understanding 3D CNC Laser Cutting Technology

- 1.3 H2: Advantages of 3D CNC Laser Cutting

- 1.4 H3: Types of 3D CNC Laser Cutting Machines

- 1.5 H4: Applications of 3D CNC Laser Cutting

- 1.6 H1: Understanding 3D CNC Laser Cutting Technology

- 1.7 H2: Advantages of 3D CNC Laser Cutting

- 1.8 H5: Factors to Consider When Choosing a 3D CNC Laser Cutting Machine

- 1.9 Conclusion

- 2 FAQs

H1: Understanding 3D CNC Laser Cutting Technology

H2: Advantages of 3D CNC Laser Cutting

Precision and Accuracy: 3D CNC laser cutting machines offer exceptional precision, with cutting tolerances of up to 0.005 inches. This enables the creation of intricate shapes and complex geometries with high accuracy.

Versatility: These machines can cut a wide range of materials, including metals, plastics, wood, and composites. This versatility makes them ideal for applications in industries such as aerospace, automotive, and medical device manufacturing.

Speed and Efficiency: 3D CNC laser cutting machines are highly efficient, capable of cutting at speeds of up to 100 inches per minute. This allows for the rapid production of large batches of parts, reducing production time and costs.

Automation: The CNC control system automates the cutting process, eliminating the need for manual intervention. This increases productivity and reduces the risk of errors.

H3: Types of 3D CNC Laser Cutting Machines

Fiber Laser Cutting Machines: These machines use a fiber laser source, which offers high power density and beam quality. They are suitable for cutting thin and medium-thickness metals.

CO2 Laser Cutting Machines: CO2 laser cutting machines utilize a carbon dioxide laser source, which provides a wider wavelength range. They are ideal for cutting thicker materials and non-metallic materials.

Hybrid Laser Cutting Machines: Hybrid machines combine the advantages of both fiber and CO2 lasers, offering a wider cutting range and increased versatility.

H4: Applications of 3D CNC Laser Cutting

In the realm of advanced manufacturing, 3D CNC laser cutting machines are revolutionizing the production of intricate and complex parts. By combining the precision of CNC technology with the versatility of laser cutting, these machines offer unparalleled capabilities for cutting a wide range of materials with exceptional accuracy and speed.

- 3d 5 Axis Laser Cutting Machine 3D 5-Axis Laser Cutting Machine: A Comprehensive Guide

- 3d Laser Cut Logo 3D Laser Cut Logo: Elevate Your Brand With Precision And Impact

- Laser Cut 3d Puzzle Free Download Laser Cut 3D Puzzle: Free Download And Assembly Guide

- 3d Laser Crystal Engraving Machine 3D Laser Crystal Engraving Machine: Unlocking Limitless Creative Possibilities

- 3d Laser Cut Acrylic Letters 3D Laser Cut Acrylic Letters: A Comprehensive Guide

H1: Understanding 3D CNC Laser Cutting Technology

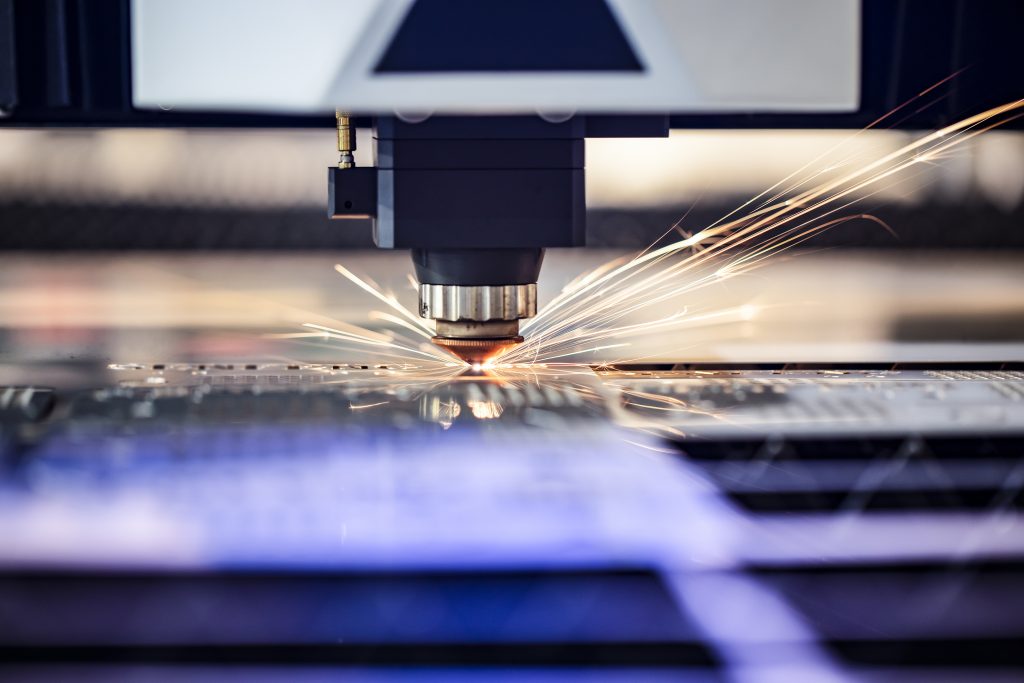

A 3D CNC laser cutting machine utilizes a computer-controlled (CNC) system to guide a laser beam along a predetermined path, creating three-dimensional cuts in the workpiece. The laser beam, typically generated by a fiber or CO2 laser source, is focused through a series of optics to produce a highly concentrated beam of light energy.

H2: Advantages of 3D CNC Laser Cutting

Precision and Accuracy: 3D CNC laser cutting machines offer exceptional precision, with cutting tolerances of up to 0.005 inches. This enables the creation of intricate shapes and complex geometries with high accuracy.

Versatility: These machines can cut a wide range of materials, including metals, plastics, wood, and composites. This versatility makes them ideal for applications in industries such as aerospace, automotive, and medical device manufacturing.

Aerospace: 3D CNC laser cutting machines are used to manufacture complex aircraft components, such as engine mounts and wing ribs.

Automotive: These machines are employed in the production of automotive parts, such as body panels, exhaust systems, and interior trim.

Medical: 3D CNC laser cutting is used to create precise medical devices, such as surgical instruments and implants.

Electronics: The technology is used to cut intricate circuit boards and electronic components with high accuracy.

H5: Factors to Consider When Choosing a 3D CNC Laser Cutting Machine

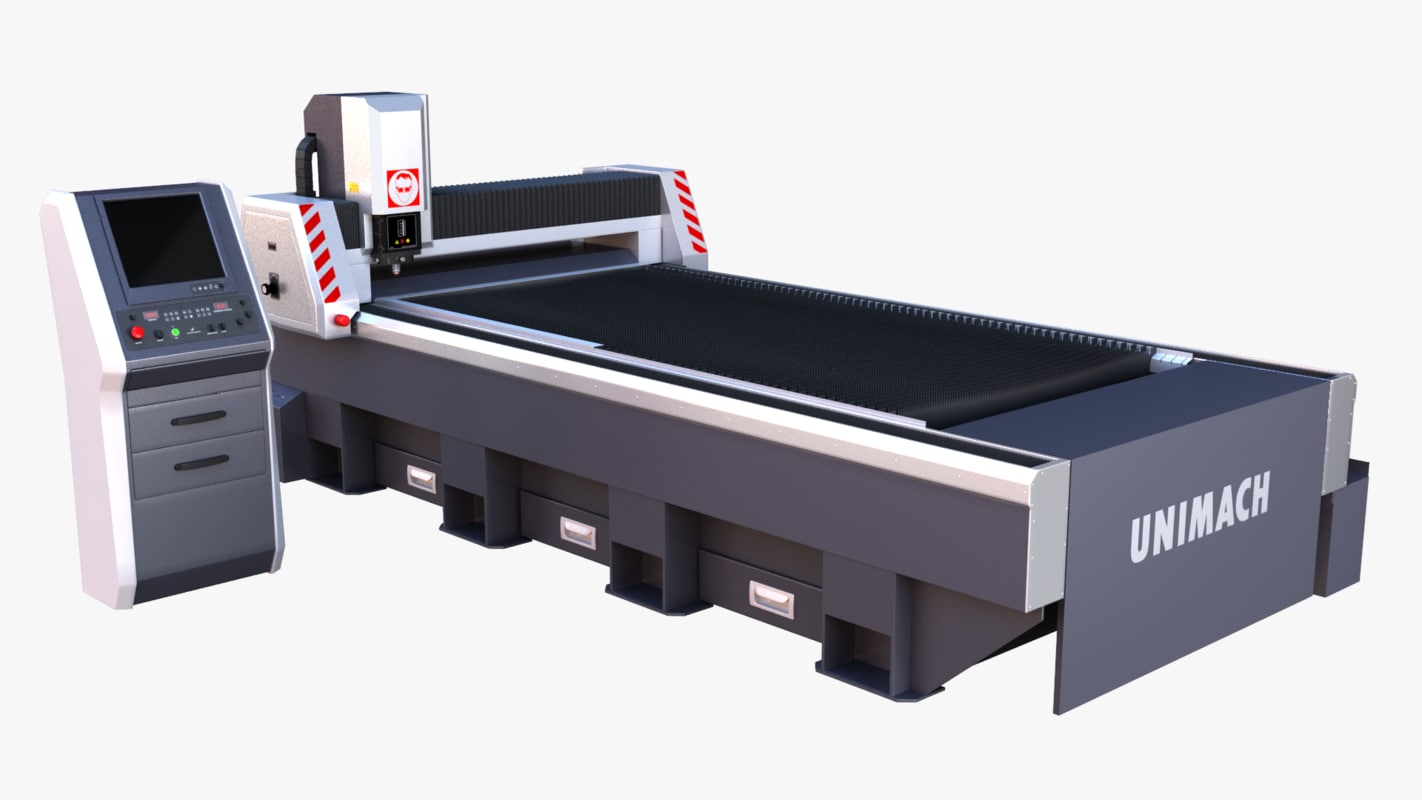

Cutting Area: Determine the maximum cutting area required for your applications.

Material Thickness: Consider the thickness of the materials you will be cutting.

Cutting Speed: Select a machine that can meet your desired cutting speed requirements.

Laser Power: Choose a laser power that is appropriate for the materials you will be cutting.

Software: Ensure that the machine is compatible with your preferred CAD/CAM software.

Conclusion

3D CNC laser cutting machines are a powerful tool for the manufacturing industry, enabling the production of complex and precise parts with exceptional speed and efficiency. By carefully considering the factors discussed in this article, you can select the right machine for your specific applications and unlock the full potential of 3D laser cutting technology.

FAQs

Q: What is the difference between a 3D CNC laser cutting machine and a traditional CNC laser cutting machine?

A: A 3D CNC laser cutting machine allows for the cutting of three-dimensional shapes, while a traditional CNC laser cutting machine is limited to two-dimensional cuts.

Q: What are the advantages of 3D CNC laser cutting over other cutting methods?

A: 3D CNC laser cutting offers higher precision, versatility, speed, and automation compared to other methods such as waterjet cutting or plasma cutting.

Q: What types of materials can be cut with a 3D CNC laser cutting machine?

A: 3D CNC laser cutting machines can cut a wide range of materials, including metals, plastics, wood, and composites.

Q: How do I choose the right 3D CNC laser cutting machine for my application?

A: Consider factors such as cutting area, material thickness, cutting speed, laser power, and software compatibility when selecting a machine.

Q: What are some of the applications of 3D CNC laser cutting?

A: 3D CNC laser cutting is used in industries such as aerospace, automotive, medical, and electronics for the production of complex and precise parts.