3D Crystal Laser Cutting Machine: A Comprehensive Guide

Introduction

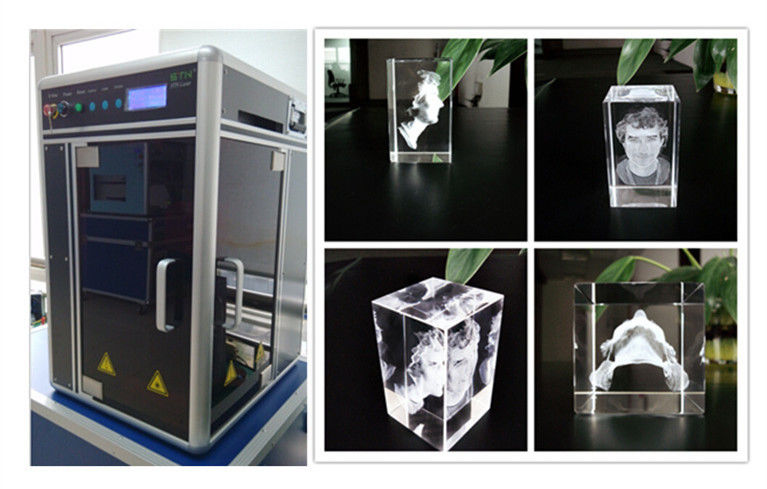

3D crystal laser cutting machines are advanced technological marvels that have revolutionized the art of crystal engraving. These machines utilize high-powered lasers to precisely cut and engrave intricate designs within the depths of crystal, creating breathtaking three-dimensional masterpieces.

Table of Content

- 1 3D Crystal Laser Cutting Machine: A Comprehensive Guide

- 1.1 Introduction

- 1.2 How 3D Crystal Laser Cutting Machines Work

- 1.3 Applications of 3D Crystal Laser Cutting Machines

- 1.4 Benefits of Using 3D Crystal Laser Cutting Machines

- 1.5 How 3D Crystal Laser Cutting Machines Work

- 1.6 Applications of 3D Crystal Laser Cutting Machines

- 1.7 Choosing the Right 3D Crystal Laser Cutting Machine

- 1.8 Safety Considerations

- 1.9 Conclusion

- 1.10 FAQs

How 3D Crystal Laser Cutting Machines Work

Applications of 3D Crystal Laser Cutting Machines

The applications of 3D crystal laser cutting machines are vast and include:

- Personalized Gifts and Awards: Creating unique and memorable gifts and awards with customized designs engraved within the crystal.

- Interior Design: Producing intricate crystal sculptures, decorative pieces, and lighting fixtures that enhance the aesthetics of homes and businesses.

- Commemorative Items: Preserving special moments and memories by engraving photos, text, and symbols into crystal keepsakes.

- Industrial Applications: Precision cutting of optical components, medical devices, and other industrial materials.

Benefits of Using 3D Crystal Laser Cutting Machines

- Sketchup For Laser Cutting SketchUp For Laser Cutting: A Comprehensive Guide

- 3d 6 Axis Laser Cutting 3D 6-Axis Laser Cutting: Revolutionizing Complex Fabrication

- 3d Laser Cut Tree 3D Laser Cut Tree: A Revolutionary Home Décor Element

- 3d Laser Cutting Machine Company 3D Laser Cutting Machine: Revolutionizing Fabrication

- Snapmaker Laser Cutting Guide Snapmaker Laser Cutting Guide: A Comprehensive Walkthrough

- Precision and Accuracy: Laser cutting ensures unparalleled precision and accuracy, enabling the creation of intricate and detailed designs.

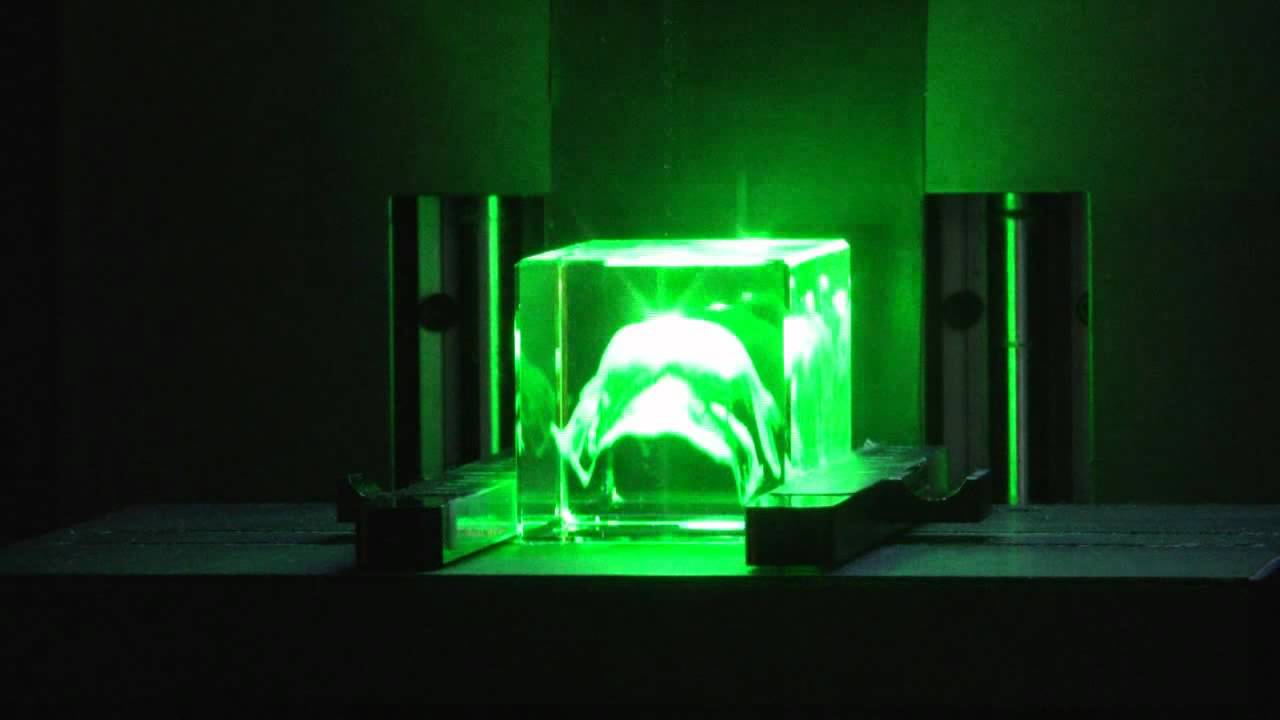

- Depth and Detail: The ability to engrave within the crystal’s depth allows for the creation of stunning 3D effects and highly realistic images.

- Versatility: 3D crystal laser cutting machines can work with various crystal types, including optical crystal, lead crystal, and fused quartz.

- Durability: Crystal engravings are permanent and highly durable, ensuring the longevity of the created pieces.

- Low Maintenance: These machines require minimal maintenance, making them cost-effective and easy to operate.

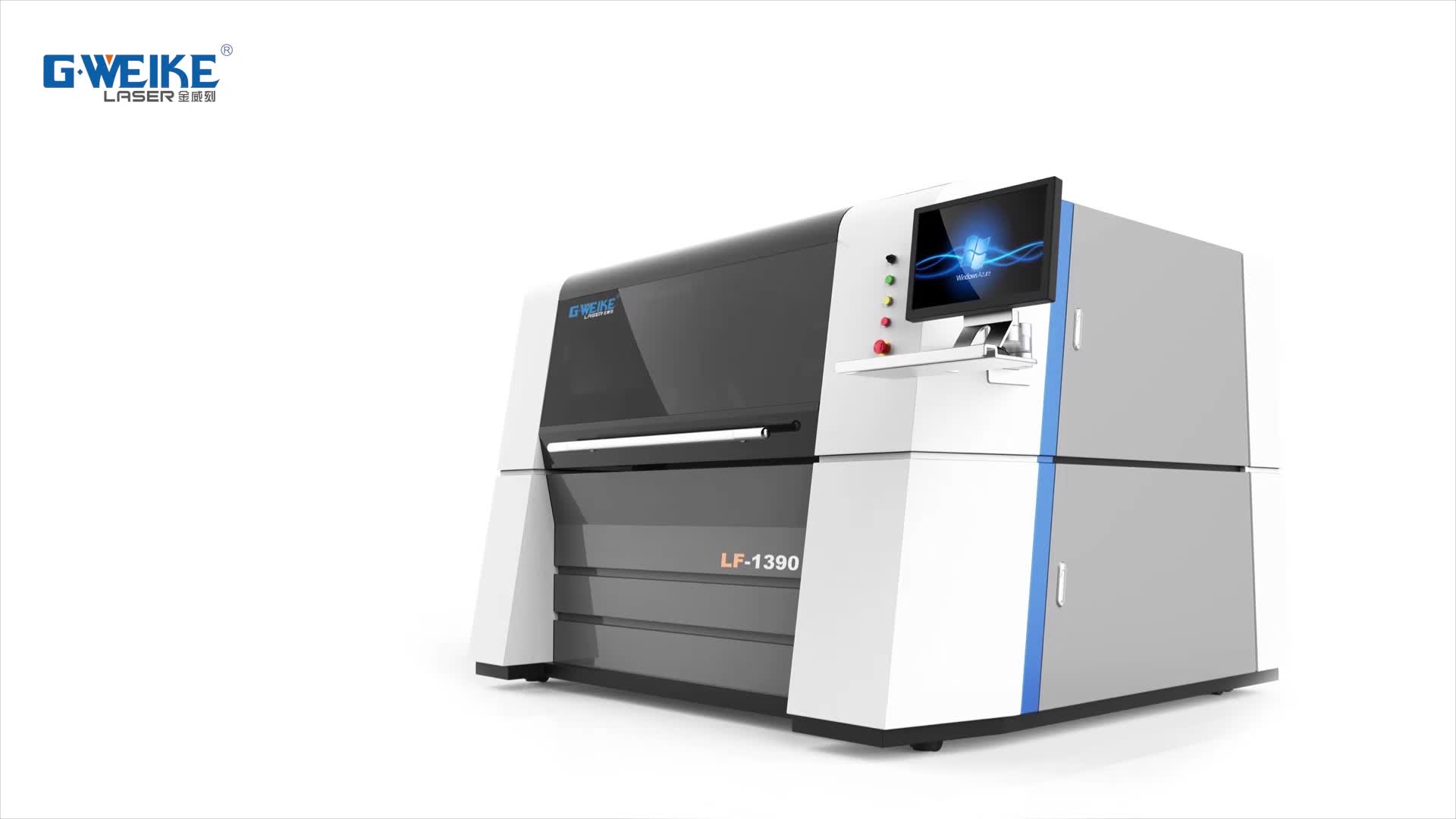

- Laser Power: The laser power determines the cutting speed and depth. Choose a machine with sufficient power for your intended applications.

- Work Area Size: The work area size determines the maximum size of the crystal that can be engraved.

- Software Features: The machine’s software should provide intuitive design tools, advanced editing capabilities, and compatibility with industry-standard file formats.

- Support and Warranty: Choose a reputable supplier that offers reliable support and a comprehensive warranty.

- Laser Safety: Wear appropriate laser safety glasses and protective clothing.

- Ventilation: Ensure adequate ventilation to remove fumes generated during cutting.

- Crystal Handling: Use proper handling techniques to avoid breaking or damaging the crystal.

3D crystal laser cutting machines are advanced technological marvels that have revolutionized the art of crystal engraving. These machines utilize high-powered lasers to precisely cut and engrave intricate designs within the depths of crystal, creating breathtaking three-dimensional masterpieces.

How 3D Crystal Laser Cutting Machines Work

3D crystal laser cutting machines operate on the principle of laser ablation, which involves directing a concentrated laser beam onto the crystal surface. The high energy of the laser beam vaporizes the crystal material, creating a clean and precise cut. By controlling the laser’s intensity, speed, and movement, the machine can create complex 3D shapes and images within the crystal.

Applications of 3D Crystal Laser Cutting Machines

The applications of 3D crystal laser cutting machines are vast and include:

Choosing the Right 3D Crystal Laser Cutting Machine

When selecting a 3D crystal laser cutting machine, consider the following factors:

Safety Considerations

Operating a 3D crystal laser cutting machine requires adherence to safety precautions:

Conclusion

3D crystal laser cutting machines are transformative tools that empower artists, designers, and manufacturers to create stunning and unique crystal masterpieces. Their precision, versatility, and durability make them an indispensable asset for a wide range of applications. By carefully selecting and operating these machines, users can unlock the limitless potential of crystal engraving and create works of art that will captivate and inspire for generations to come.

FAQs

Q: What materials can be cut with a 3D crystal laser cutting machine?

A: Various crystal types, including optical crystal, lead crystal, and fused quartz.

Q: Can I engrave photos or images using a 3D crystal laser cutting machine?

A: Yes, these machines can engrave detailed photos and images with exceptional depth and realism.

Q: How long does it take to engrave a crystal?

A: The engraving time varies depending on the size, complexity, and depth of the design.

Q: Are 3D crystal laser cutting machines difficult to operate?

A: With proper training and software proficiency, these machines are relatively easy to operate.

Q: How do I maintain a 3D crystal laser cutting machine?

A: Regular cleaning and occasional maintenance are recommended to ensure optimal performance and longevity.