3D Software for Laser Cutting: A Comprehensive Guide

Introduction

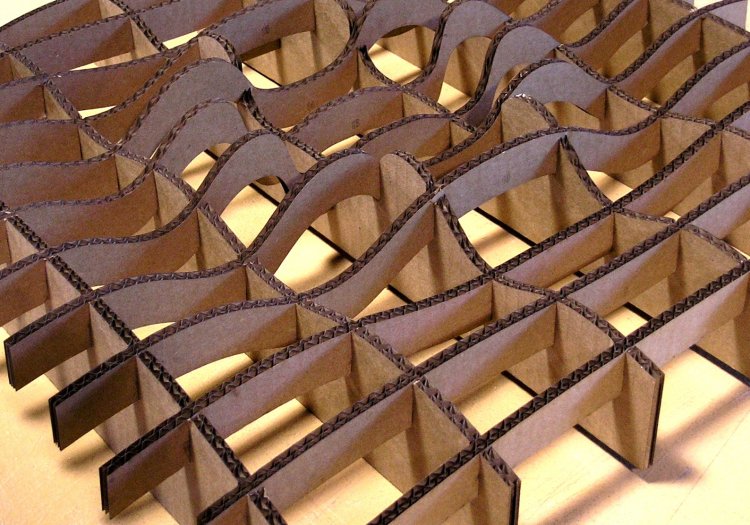

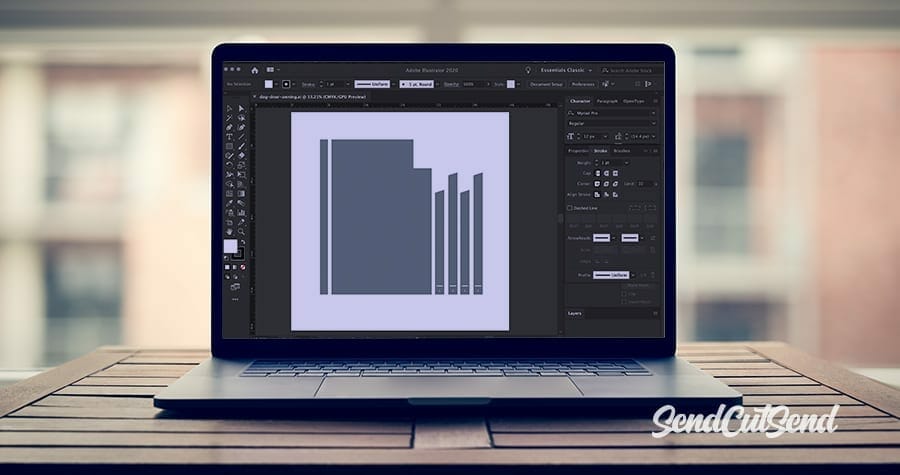

Laser cutting has revolutionized the manufacturing industry, enabling precision cutting of intricate designs in a wide range of materials. To harness the full potential of laser cutting, specialized 3D software is essential for designing, simulating, and controlling the cutting process. This article provides an in-depth exploration of the best 3D software for laser cutting, guiding you through their capabilities and benefits.

Table of Content

- 1 3D Software for Laser Cutting: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Essential Features of 3D Laser Cutting Software

- 1.3 H1: Essential Features of 3D Laser Cutting Software

- 1.4 H2: Top 3D Software for Laser Cutting

- 1.5 H3: Benefits of Using 3D Laser Cutting Software

- 1.6 H4: Conclusion

- 1.7 H5: Frequently Asked Questions (FAQs)

H1: Essential Features of 3D Laser Cutting Software

- Seamless integration with CAD software (e.g., SolidWorks, AutoCAD)

- Import and edit 3D models in various formats (e.g., STL, STEP, IGES)

2. Design Optimization

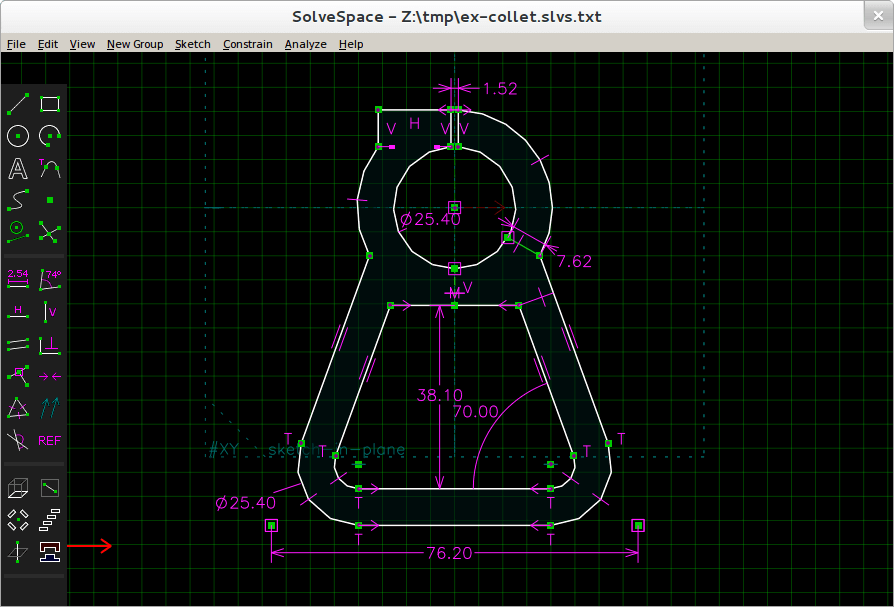

- Advanced modeling tools for creating complex geometries

- Parametric design capabilities for quick and easy adjustments

- Automated features for nesting and material utilization

Laser cutting has revolutionized the manufacturing industry, enabling precision cutting of intricate designs in a wide range of materials. To harness the full potential of laser cutting, specialized 3D software is essential for designing, simulating, and controlling the cutting process. This article provides an in-depth exploration of the best 3D software for laser cutting, guiding you through their capabilities and benefits.

- 3d Crystal Laser Cutting Machine 3D Crystal Laser Cutting Machine: A Comprehensive Guide

- Laser Cutter Comparable To Glowforge Laser Cutter Comparable To Glowforge: A Comprehensive Guide

- Laser Cut 3d Dragon Laser Cut 3D Dragon: A Detailed Guide To Crafting A Majestic Masterpiece

- Shapeways Laser Cutting Shapeways Laser Cutting: A Comprehensive Guide To Advanced Manufacturing

- 3d Laser Cut Wood 3D Laser Cut Wood: Unlocking Intricate Designs And Precision Craftsmanship

H1: Essential Features of 3D Laser Cutting Software

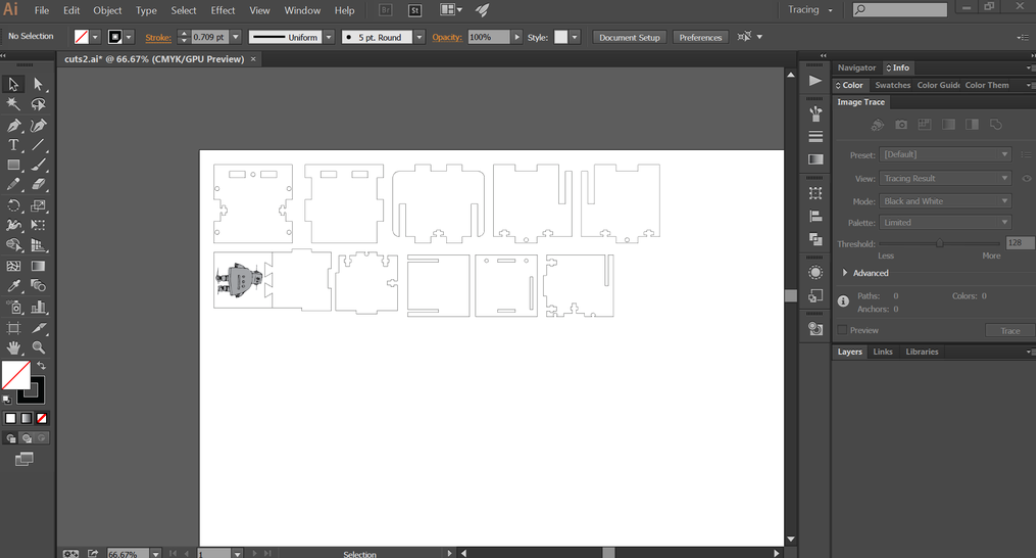

1. CAD Compatibility

- Seamless integration with CAD software (e.g., SolidWorks, AutoCAD)

- Import and edit 3D models in various formats (e.g., STL, STEP, IGES)

- Realistic simulation of the laser cutting process

- Collision detection and path optimization to prevent errors

- Real-time visualization of the cutting path

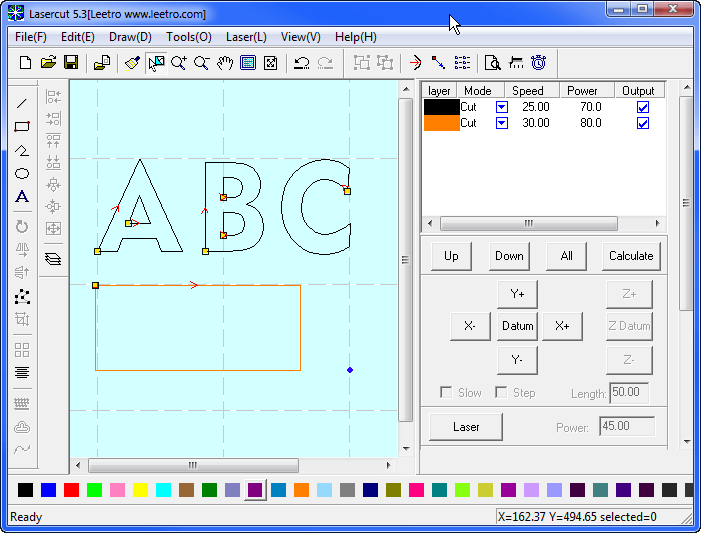

- Direct communication with laser cutting machines

- Generation of machine-specific cutting parameters

- Monitoring and control of the cutting process in real-time

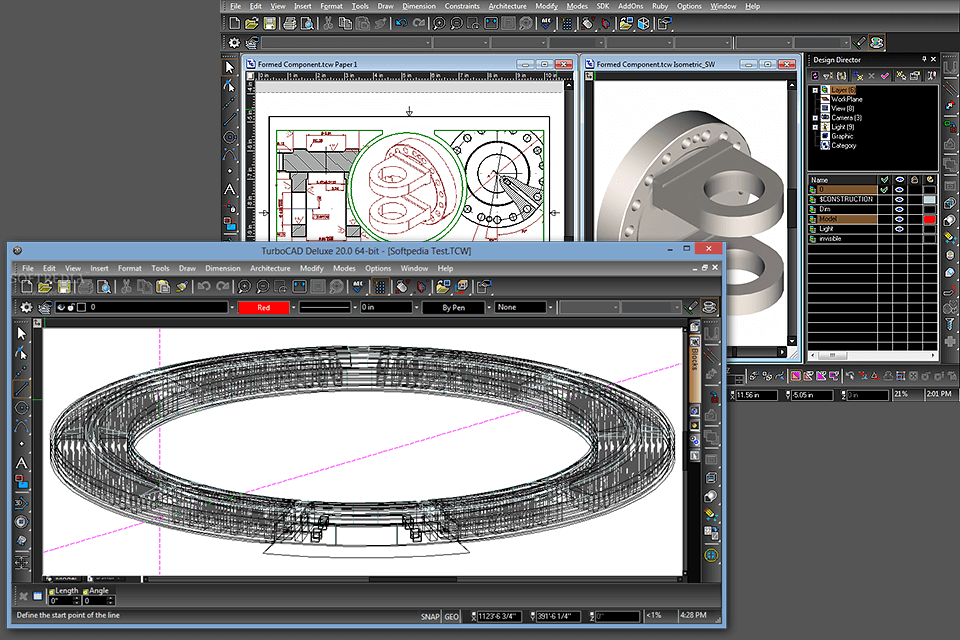

- Comprehensive CAD/CAM suite with dedicated laser cutting module

- Advanced nesting algorithms for optimal material usage

- Powerful simulation tools for accurate path planning

- Specialized software designed for CNC machining and laser cutting

- Intuitive interface with a wide range of modeling and editing tools

- Integrated toolpath optimization and simulation capabilities

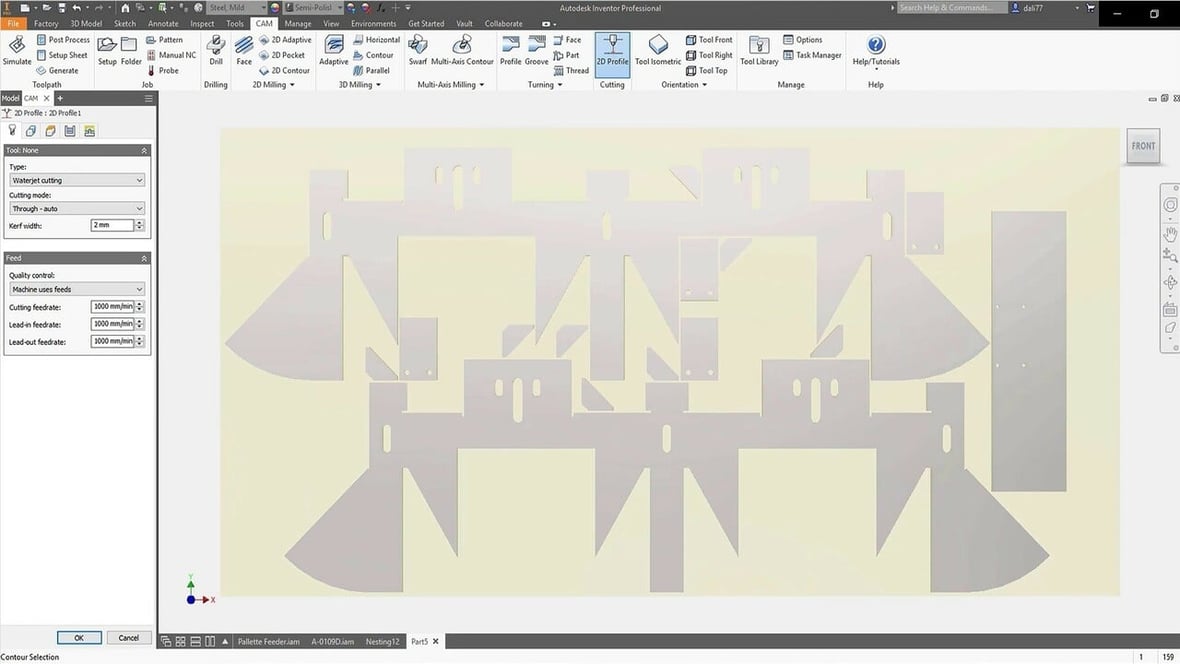

- High-end CAD/CAM software for complex manufacturing processes

- Comprehensive support for laser cutting, including multi-axis cutting

- Advanced collision avoidance and real-time monitoring

- Precise control over cutting parameters ensures consistent and high-quality results.

- Simulation tools help eliminate errors and prevent costly mistakes.

- Automated design and nesting features optimize workflow and reduce production time.

- Direct machine control enables seamless integration into manufacturing processes.

- Advanced nesting algorithms minimize material usage and reduce production costs.

- Simulation tools allow for optimization of cutting paths to avoid unnecessary material waste.

- Simulation capabilities detect potential collisions and prevent equipment damage.

- Real-time monitoring ensures safe operation and reduces the risk of accidents.

- Compatibility with your CAD software

- Design capabilities and simulation tools

- Machine control and monitoring features

- Ease of use and user interface

- Reduced production time through automated design and nesting

- Increased accuracy and precision for consistent results

- Minimized material waste for cost savings

- Enhanced safety through collision detection and real-time monitoring

- The learning curve varies depending on the software and your prior experience.

- Most software offers training materials and support to assist users.

- Consider investing in training to maximize the benefits of the software.

3. Simulation and Verification

4. Machine Control

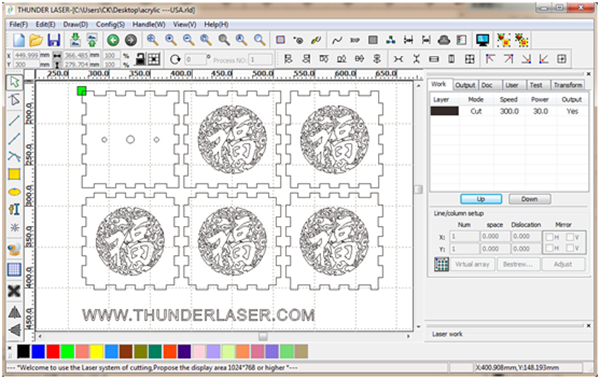

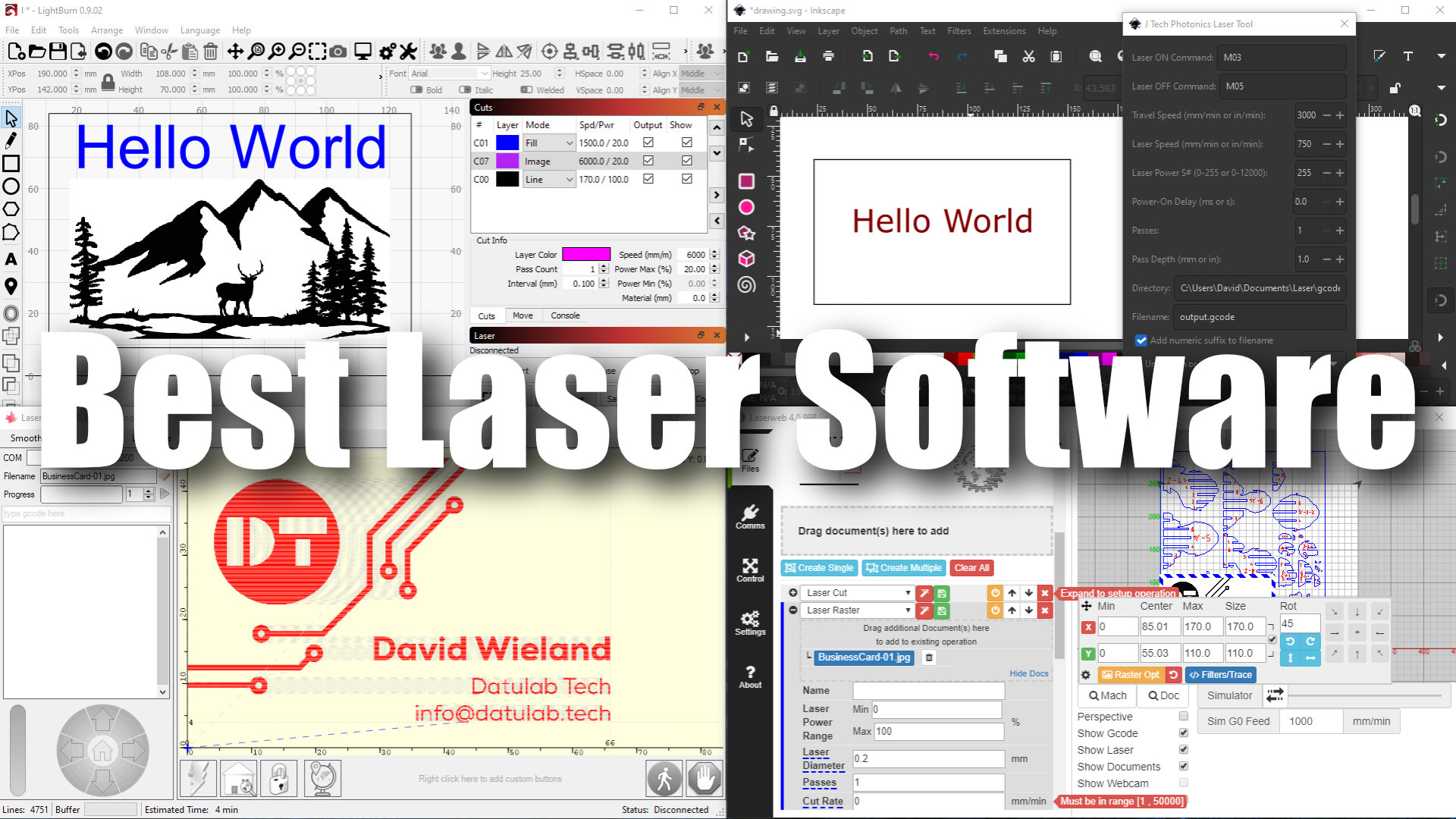

H2: Top 3D Software for Laser Cutting

1. SolidCAM

2. RhinoCAM

3. Esprit

H3: Benefits of Using 3D Laser Cutting Software

1. Increased Accuracy and Precision

2. Enhanced Productivity

3. Reduced Material Waste

4. Improved Safety

H4: Conclusion

3D software for laser cutting is an indispensable tool for unlocking the full potential of this advanced manufacturing technology. By providing essential features such as CAD compatibility, design optimization, simulation, and machine control, these software solutions empower manufacturers to produce complex and precise parts with increased accuracy, productivity, and safety.

H5: Frequently Asked Questions (FAQs)

1. What are the key considerations when choosing 3D laser cutting software?

2. How can 3D laser cutting software improve my manufacturing process?

3. What is the learning curve for 3D laser cutting software?