Laser Cutting for 3D Printing: A Comprehensive Guide

Introduction

Laser cutting has emerged as a revolutionary technology in the realm of 3D printing, enabling the fabrication of intricate and high-precision objects with unparalleled speed and efficiency. This article delves into the multifaceted world of laser cutting for 3D printing, exploring its principles, applications, advantages, and considerations.

Table of Content

- 1 Laser Cutting for 3D Printing: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Principles of Laser Cutting

- 1.3 Types of Laser Cutting Machines

- 1.4 Applications of Laser Cutting in 3D Printing

- 1.5 Principles of Laser Cutting

- 1.6 Types of Laser Cutting Machines

- 1.7 Advantages of Laser Cutting for 3D Printing

- 1.8 Considerations for Laser Cutting in 3D Printing

- 1.9 Conclusion

- 1.10 Frequently Asked Questions (FAQs)

Principles of Laser Cutting

Types of Laser Cutting Machines

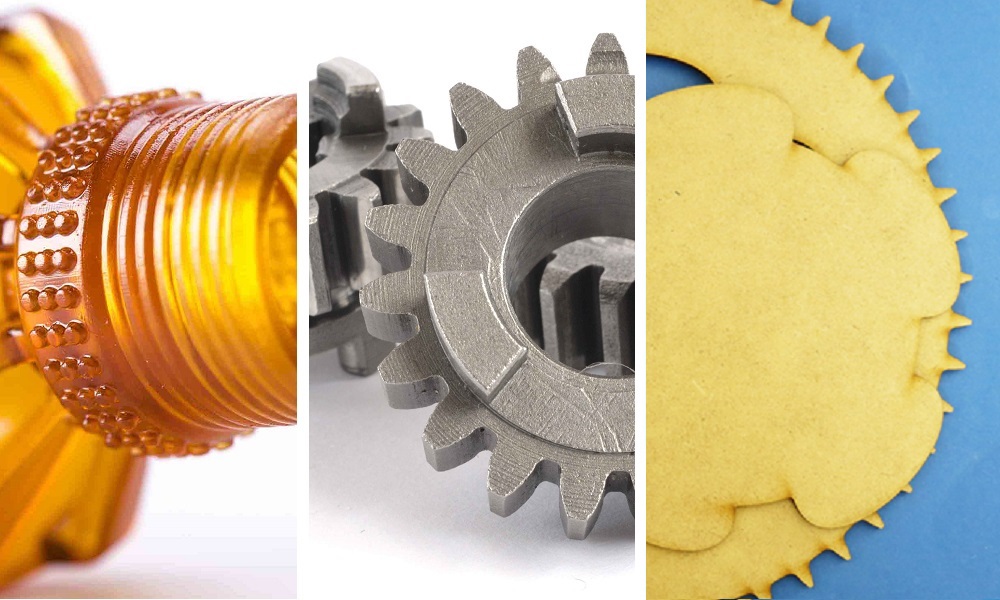

Various types of laser cutting machines are available, each tailored to specific materials and applications:

- CO2 Laser Cutters: Suitable for cutting non-metals like acrylic, wood, and fabrics.

- Fiber Laser Cutters: Ideal for cutting metals such as stainless steel, aluminum, and brass.

- Hybrid Laser Cutters: Combine CO2 and fiber lasers to cut a wider range of materials.

Applications of Laser Cutting in 3D Printing

Laser cutting plays a crucial role in 3D printing, particularly in the following applications:

- 3d Crystal Laser Cutting Machine 3D Crystal Laser Cutting Machine: A Comprehensive Guide

- 3d Laser Cutting 3D Laser Cutting: A Comprehensive Guide

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

- Laser Cutting Free 3d Dxf Files H1: Unleashing Creativity: Laser Cutting Free 3D DXF Files

- Laser Cut 3d Rose Laser Cut 3D Rose: A Guide To Intricate And Stunning Creations

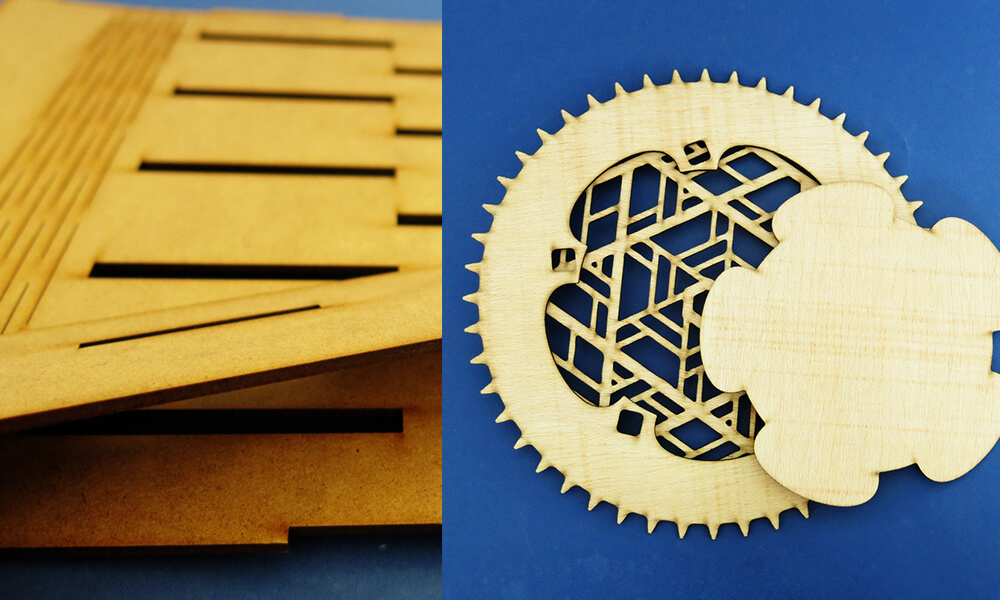

- Prototyping: Rapid prototyping of functional parts and assemblies.

- Model Making: Creating intricate models for architectural, design, and engineering projects.

- Jewelry Making: Fabrication of custom jewelry pieces with fine details.

- Medical Devices: Production of surgical instruments, implants, and other medical devices with high precision.

- Aerospace Components: Manufacturing lightweight and durable components for aircraft and spacecraft.

- Precision: Laser beams provide unparalleled precision, allowing for the creation of highly accurate and detailed parts.

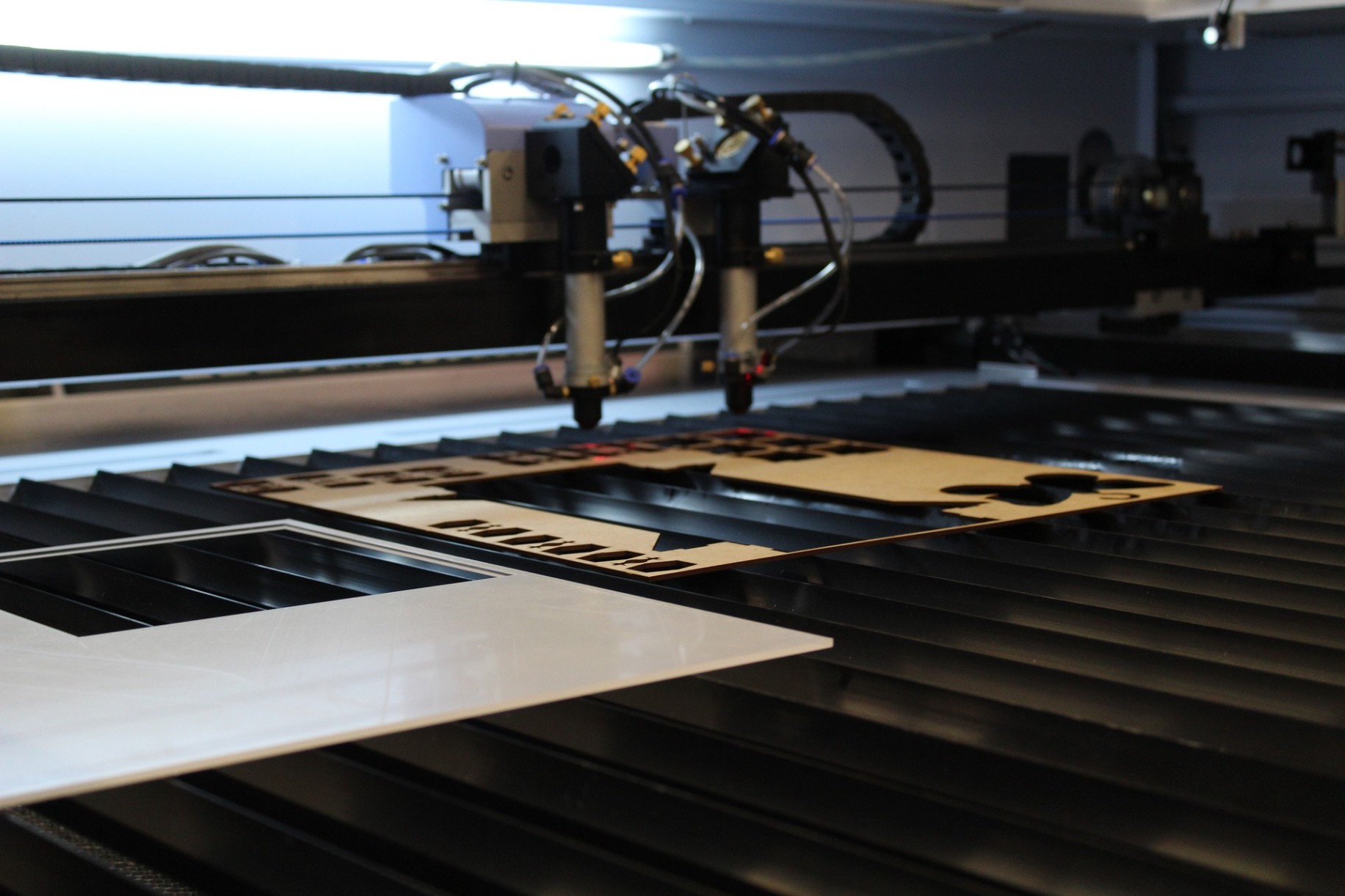

- Speed: Laser cutting machines operate at high speeds, significantly reducing production time.

- Versatility: Laser cutting can process a wide range of materials, including metals, plastics, and composites.

- Minimal Waste: Laser cutting minimizes material waste compared to other cutting techniques.

- Automation: Laser cutting machines can be automated, enabling continuous production without manual intervention.

- Material Compatibility: Ensure the material is compatible with the laser cutting machine and the desired cutting parameters.

- Safety: Laser cutting involves high-intensity beams, so proper safety precautions, such as protective eyewear and ventilation, must be followed.

- Software Compatibility: Verify that the laser cutting machine is compatible with the 3D modeling software used for designing the parts.

- Cost: Consider the initial investment and ongoing operating costs of laser cutting equipment.

Laser cutting has emerged as a revolutionary technology in the realm of 3D printing, enabling the fabrication of intricate and high-precision objects with unparalleled speed and efficiency. This article delves into the multifaceted world of laser cutting for 3D printing, exploring its principles, applications, advantages, and considerations.

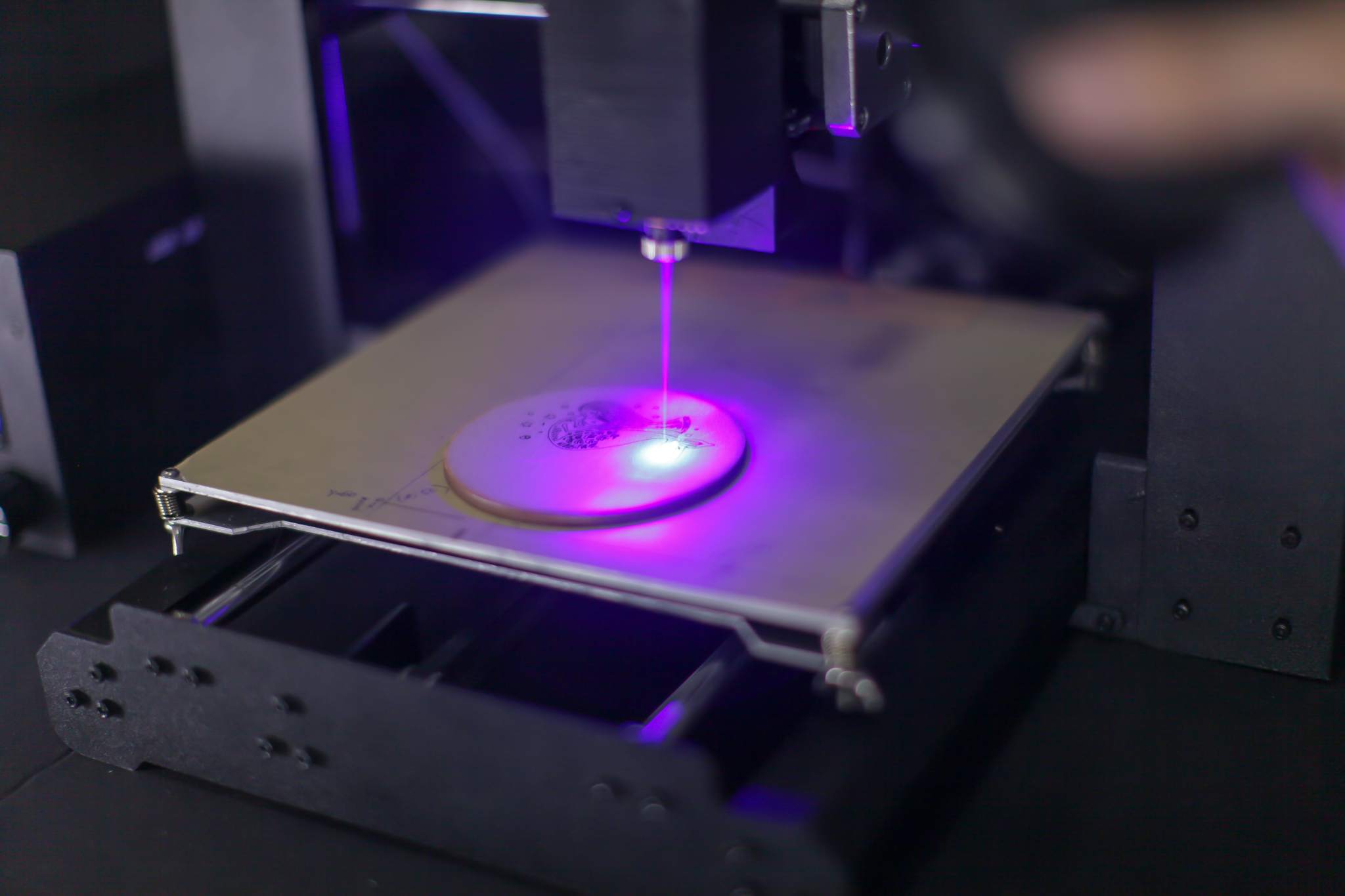

Principles of Laser Cutting

Laser cutting involves directing a highly focused laser beam onto a material, vaporizing or melting it along the desired cutting path. The laser beam is generated by a laser source, such as a CO2 or fiber laser, and is guided through a series of mirrors and lenses to precisely control its position and intensity.

Types of Laser Cutting Machines

Various types of laser cutting machines are available, each tailored to specific materials and applications:

Advantages of Laser Cutting for 3D Printing

Laser cutting offers numerous advantages over traditional cutting methods for 3D printing:

Considerations for Laser Cutting in 3D Printing

When considering laser cutting for 3D printing, several factors should be taken into account:

Conclusion

Laser cutting has revolutionized the field of 3D printing, enabling the production of intricate and high-precision objects with unprecedented speed and efficiency. Its versatility, precision, and automation capabilities make it an indispensable tool for prototyping, model making, jewelry making, and various industrial applications. By understanding the principles, applications, and considerations of laser cutting, users can leverage this technology to unlock a world of possibilities in 3D printing.

Frequently Asked Questions (FAQs)

Q: What materials can be laser cut for 3D printing?

A: Laser cutting can process a wide range of materials, including acrylic, wood, fabrics, metals, plastics, and composites.

Q: How precise is laser cutting?

A: Laser cutting offers exceptional precision, allowing for the creation of highly accurate and detailed parts with tolerances in the micrometer range.

Q: Is laser cutting safe?

A: Laser cutting involves high-intensity beams, so proper safety precautions, such as protective eyewear, ventilation, and proper training, must be followed to minimize risks.

Q: How fast is laser cutting?

A: Laser cutting machines operate at high speeds, significantly reducing production time compared to traditional cutting methods.

Q: How expensive is laser cutting equipment?

A: The cost of laser cutting equipment varies depending on the type of laser, power, and features. It is important to consider both the initial investment and ongoing operating costs.