3D Models for Laser Cutting: Unleashing Precision and Creativity

Introduction

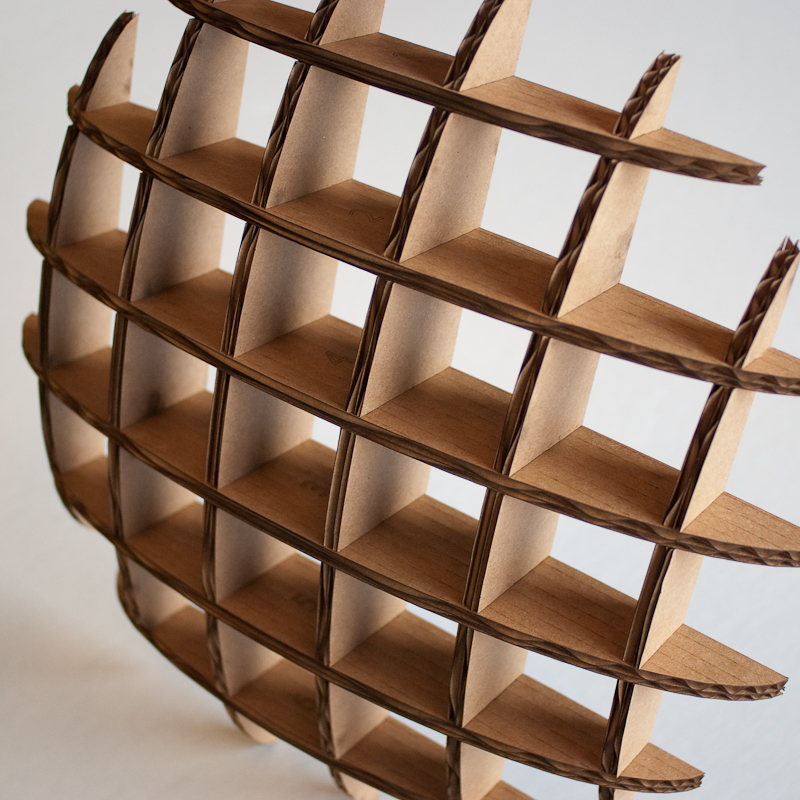

Laser cutting has revolutionized various industries, enabling precise and intricate designs to be realized with ease. 3D models serve as the foundation for laser cutting, providing the digital blueprints that guide the laser’s path. This article explores the realm of 3D models for laser cutting, delving into their importance, optimization techniques, and a comprehensive guide to sourcing and using them.

Table of Content

- 1 3D Models for Laser Cutting: Unleashing Precision and Creativity

- 1.1 Introduction

- 1.2 Importance of 3D Models for Laser Cutting

- 1.3 Optimization Techniques for 3D Models

- 1.4 Importance of 3D Models for Laser Cutting

- 1.5 Sourcing 3D Models for Laser Cutting

- 1.6 Using 3D Models in Laser Cutting

- 1.7 Conclusion

- 1.8 FAQs

Importance of 3D Models for Laser Cutting

- Define Precise Designs: 3D models provide an accurate representation of the desired cut, ensuring precision and eliminating guesswork.

- Optimize Material Usage: By visualizing the cut in 3D, users can minimize material waste and maximize efficiency.

- Enable Complex Designs: 3D models allow for the creation of intricate and complex designs that would be difficult or impossible to achieve manually.

- Facilitate Simulation and Testing: 3D models can be used in simulation software to test the cut before production, identifying potential issues and optimizing the process.

Optimization Techniques for 3D Models

To ensure optimal results in laser cutting, it is crucial to optimize 3D models for the process:

- Model Complexity: Keep models as simple as possible while maintaining the necessary detail.

- Laser Cut 3d Pop Cards Laser Cut 3D Pop Cards: A Captivating Expression Of Creativity And Emotion

- Dxf 3d Laser Cut H1: Unleashing The Power Of DXF 3D Laser Cutting: A Comprehensive Guide

- Laser Cutting And 3d Printing Projects Laser Cutting And 3D Printing Projects: A Comprehensive Guide

- 3d Design For Laser Cutting 3D Design For Laser Cutting: A Comprehensive Guide

- Simple 3d Laser Cut Simple 3D Laser Cut: A Comprehensive Guide

- Define Precise Designs: 3D models provide an accurate representation of the desired cut, ensuring precision and eliminating guesswork.

- Optimize Material Usage: By visualizing the cut in 3D, users can minimize material waste and maximize efficiency.

- Units and Scale: Ensure the model’s units match the laser cutter’s requirements and that the scale is appropriate.

- File Format: Use file formats compatible with laser cutting software, such as DXF, SVG, or STL.

- Closed Paths: All paths in the model must be closed to ensure proper cutting.

- Line Thickness: Adjust line thickness to match the laser cutter’s beam width.

- Online Libraries: Platforms like Thingiverse, MyMiniFactory, and Cults offer a vast collection of free and paid models.

- Custom Design Services: Professional designers can create custom models based on your specifications.

- Scanning: 3D scanners can capture physical objects and convert them into digital models.

- Modeling Software: Software such as Blender, SketchUp, and Fusion 360 allow users to create their own models.

- Import the Model: Import the 3D model into your laser cutting software.

- Adjust Settings: Set the laser parameters (power, speed, etc.) according to the material and desired cut quality.

- Position the Model: Align the model on the cutting bed and set the origin point.

- Generate Toolpath: The software generates a toolpath based on the 3D model.

- Cut the Material: Execute the toolpath to cut the material using the laser.

Laser cutting has revolutionized various industries, enabling precise and intricate designs to be realized with ease. 3D models serve as the foundation for laser cutting, providing the digital blueprints that guide the laser’s path. This article explores the realm of 3D models for laser cutting, delving into their importance, optimization techniques, and a comprehensive guide to sourcing and using them.

Importance of 3D Models for Laser Cutting

3D models are essential for laser cutting as they:

Sourcing 3D Models for Laser Cutting

There are various sources for obtaining 3D models for laser cutting:

Using 3D Models in Laser Cutting

Once a 3D model is obtained, follow these steps to use it in laser cutting:

Conclusion

3D models play a pivotal role in laser cutting, enabling precise and complex designs to be realized with ease. By optimizing models for the process and leveraging various sourcing options, users can achieve exceptional results. With the advancements in laser cutting technology and the availability of 3D modeling tools, the possibilities for innovation and creativity are endless.

FAQs

Q: What file formats are suitable for laser cutting?

A: DXF, SVG, and STL are commonly used file formats for laser cutting.

Q: How can I optimize 3D models for laser cutting?

A: Keep models simple, use appropriate units, ensure closed paths, and adjust line thickness to match the laser’s beam width.

Q: Where can I find free 3D models for laser cutting?

A: Online libraries like Thingiverse and MyMiniFactory offer a wide selection of free models.

Q: What is the best software for creating custom 3D models for laser cutting?

A: Blender, SketchUp, and Fusion 360 are popular software options for creating custom models.

Q: How can I minimize material waste in laser cutting?

A: Use 3D models to visualize the cut and optimize material placement to reduce waste.