3D Laser Cutting: A Revolutionary Technology for Complex Fabrication

Introduction

3D laser cutting, also known as three-dimensional laser cutting, has emerged as a groundbreaking technology that enables the precise and intricate fabrication of complex parts and prototypes from various materials. This advanced technique utilizes a focused laser beam to cut through materials in a three-dimensional space, creating objects with intricate geometries and exceptional accuracy.

Table of Content

- 1 3D Laser Cutting: A Revolutionary Technology for Complex Fabrication

- 1.1 Introduction

- 1.2 How Does 3D Laser Cutting Work?

- 1.3 Key Advantages of 3D Laser Cutting

- 1.4 Applications of 3D Laser Cutting

- 1.5 How Does 3D Laser Cutting Work?

- 1.6 Key Advantages of 3D Laser Cutting

- 1.7 Types of 3D Laser Cutting Machines

- 1.8 Considerations for Choosing a 3D Laser Cutting Machine

- 1.9 Conclusion

- 1.10 FAQs

How Does 3D Laser Cutting Work?

Key Advantages of 3D Laser Cutting

1. Precision and Accuracy: 3D laser cutting offers exceptional precision and accuracy, allowing for the production of parts with tight tolerances and intricate details.

2. Complex Geometries: Unlike traditional cutting methods, 3D laser cutting enables the fabrication of complex geometries and organic shapes, opening up new possibilities for design and innovation.

3. Material Versatility: 3D laser cutting can process a wide range of materials, including metals, plastics, wood, and composites, providing flexibility in material selection.

4. High Speed and Efficiency: Laser cutting is a relatively fast and efficient process, reducing production time and increasing productivity.

5. Minimal Waste: The precise nature of 3D laser cutting minimizes material waste, leading to cost savings and reduced environmental impact.

Applications of 3D Laser Cutting

The applications of 3D laser cutting span various industries, including:

1. Aerospace: Fabrication of lightweight and complex components for aircraft and spacecraft.

2. Automotive: Production of intricate parts for engines, body panels, and interior components.

3D laser cutting, also known as three-dimensional laser cutting, has emerged as a groundbreaking technology that enables the precise and intricate fabrication of complex parts and prototypes from various materials. This advanced technique utilizes a focused laser beam to cut through materials in a three-dimensional space, creating objects with intricate geometries and exceptional accuracy.

- 3d Laser Cutting Chess 3D Laser Cutting Chess: A Revolution In The Game Of Kings

- 3d Laser Cut Logo 3D Laser Cut Logo: Elevate Your Brand With Precision And Impact

- 3d Laser Cut Wooden Models For Sale 3D Laser Cut Wooden Models For Sale: A Comprehensive Guide

- 3d Laser Cutting Adelaide 3D Laser Cutting Adelaide: Revolutionizing Fabrication In South Australia

- 3d Laser Cut Model 3D Laser Cut Models: A Comprehensive Guide

How Does 3D Laser Cutting Work?

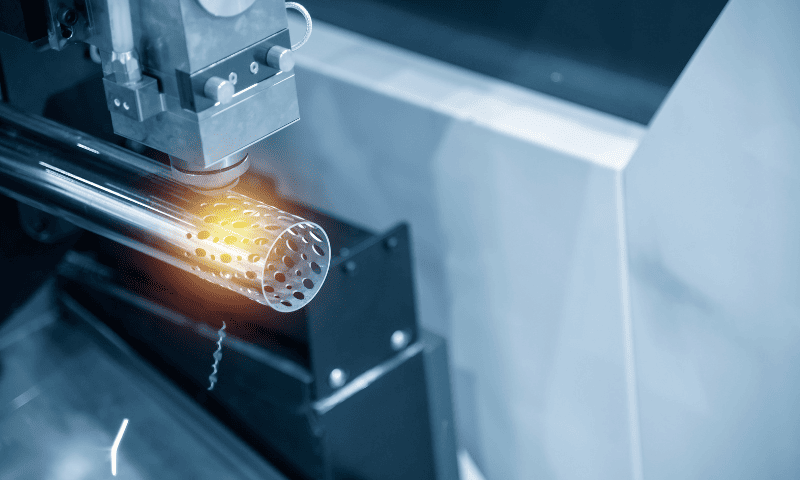

3D laser cutting involves directing a high-powered laser beam onto the surface of a material. The laser’s energy melts, vaporizes, or burns the material at the point of contact, creating a narrow kerf (cut). The laser beam is guided by a computer-aided design (CAD) file, which defines the desired shape and dimensions of the object. The laser head moves along the designated path, cutting the material layer by layer to produce the final 3D shape.

Key Advantages of 3D Laser Cutting

1. Precision and Accuracy: 3D laser cutting offers exceptional precision and accuracy, allowing for the production of parts with tight tolerances and intricate details.

2. Complex Geometries: Unlike traditional cutting methods, 3D laser cutting enables the fabrication of complex geometries and organic shapes, opening up new possibilities for design and innovation.

3. Medical: Creation of surgical instruments, prosthetics, and medical devices with high precision.

4. Electronics: Manufacturing of circuit boards, connectors, and other electronic components.

5. Architecture: Cutting of decorative elements, custom panels, and architectural models.

Types of 3D Laser Cutting Machines

There are two main types of 3D laser cutting machines:

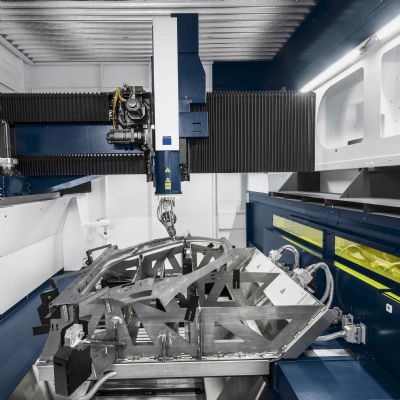

1. Gantry-Based Machines: These machines feature a gantry that moves the laser head along the X and Y axes, while the material is positioned on a fixed table.

2. Robotic Arm Machines: These machines utilize a robotic arm to manipulate the laser head, providing greater flexibility in cutting angles and complex geometries.

Considerations for Choosing a 3D Laser Cutting Machine

When selecting a 3D laser cutting machine, it is crucial to consider factors such as:

1. Material Compatibility: Ensure that the machine can cut the desired materials.

2. Cutting Speed and Accuracy: Determine the required speed and accuracy for the intended applications.

3. Machine Size and Workspace: Consider the size of the parts to be cut and the available workspace.

4. Software Compatibility: Ensure compatibility with the CAD software used for designing the parts.

5. Maintenance and Support: Evaluate the availability of maintenance and technical support services.

Conclusion

3D laser cutting has revolutionized the manufacturing industry, enabling the production of complex and intricate parts with exceptional precision and accuracy. Its versatility, efficiency, and ability to process a wide range of materials make it an ideal solution for various applications across multiple industries. As technology continues to advance, 3D laser cutting will undoubtedly play an increasingly significant role in shaping the future of manufacturing and innovation.

FAQs

1. What is the difference between 3D laser cutting and traditional laser cutting?

3D laser cutting involves cutting materials in a three-dimensional space, while traditional laser cutting is limited to two-dimensional cuts.

2. Can 3D laser cutting be used on any material?

3D laser cutting can process a wide range of materials, but the specific materials compatible will vary depending on the machine’s capabilities.

3. How accurate is 3D laser cutting?

3D laser cutting offers exceptional accuracy, typically within a few micrometers.

4. Is 3D laser cutting a fast process?

Yes, 3D laser cutting is a relatively fast and efficient process, reducing production time.

5. What are the benefits of using 3D laser cutting over other fabrication methods?

3D laser cutting offers precision, complex geometries, material versatility, high speed, and minimal waste.