3D Laser Cutting Machine Suppliers: A Comprehensive Guide

Introduction

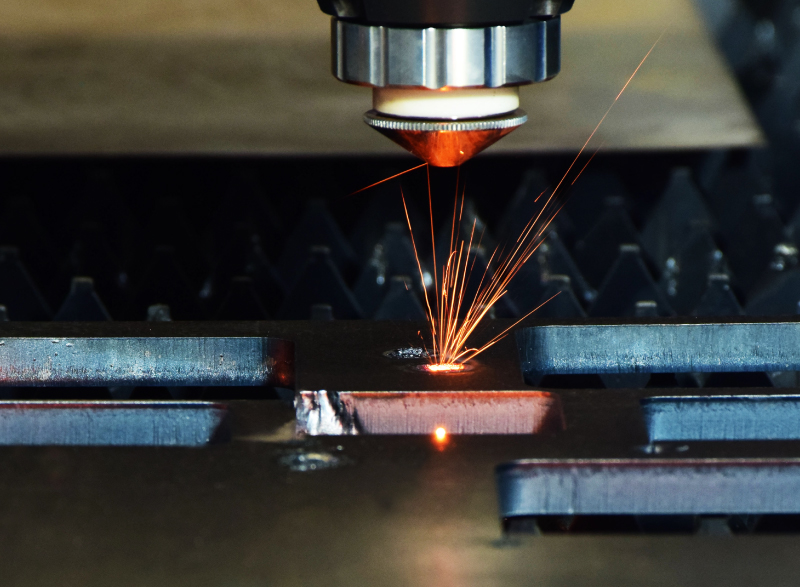

3D laser cutting machines have revolutionized manufacturing industries, enabling intricate and precise cutting of various materials. Finding reliable suppliers for these advanced machines is crucial for businesses seeking to enhance their production capabilities. This article provides an in-depth guide to 3D laser cutting machine suppliers, covering factors to consider, key features to evaluate, and recommendations for choosing the right supplier.

Table of Content

- 1 3D Laser Cutting Machine Suppliers: A Comprehensive Guide

- 1.1 H1: Factors to Consider When Choosing a 3D Laser Cutting Machine Supplier

- 1.2 H2: Key Features to Evaluate in 3D Laser Cutting Machines

- 1.3 H1: Factors to Consider When Choosing a 3D Laser Cutting Machine Supplier

- 1.4 H3: Recommendations for Choosing the Right 3D Laser Cutting Machine Supplier

- 1.5 Conclusion

- 1.6 FAQs

H1: Factors to Consider When Choosing a 3D Laser Cutting Machine Supplier

A supplier’s reputation within the industry is a testament to their reliability, quality of products, and customer service. Look for suppliers with a proven track record of success and positive customer testimonials.

2. Product Range and Customization

Suppliers should offer a wide range of 3D laser cutting machines to cater to different industry needs. They should also provide customization options to tailor machines to specific requirements.

3. Technical Support and Service

Technical support is essential for troubleshooting and maintaining laser cutting machines. Choose suppliers who offer prompt and knowledgeable support, as well as on-site service and maintenance contracts.

4. Cost and Payment Terms

Price is a significant factor, but it should not be the sole consideration. Evaluate the overall value for money, including the quality of the machine, support services, and warranty. Inquire about payment terms and financing options.

5. Location and Lead Times

Consider the supplier’s location and lead times for machine delivery. Proximity to your business can facilitate faster delivery and service. Long lead times can impact production schedules.

H2: Key Features to Evaluate in 3D Laser Cutting Machines

3D laser cutting machines have revolutionized manufacturing industries, enabling intricate and precise cutting of various materials. Finding reliable suppliers for these advanced machines is crucial for businesses seeking to enhance their production capabilities. This article provides an in-depth guide to 3D laser cutting machine suppliers, covering factors to consider, key features to evaluate, and recommendations for choosing the right supplier.

- 3d Laser Cut Lace Fabric 3D Laser Cut Lace Fabric: A Revolution In Textile Design

- 3d Laser Cutting Software 3D Laser Cutting Software: A Comprehensive Guide To Revolutionizing Your Fabrication

- Laser Cut 3d Topographic Wood Maps Laser Cut 3D Topographic Wood Maps: Unveiling The Earth’s Contours In Intricate Detail

- 3d Model To Laser Cut H1: 3D Model To Laser Cut: A Comprehensive Guide To Converting Digital Designs Into Tangible Objects

- 3d Laser Cut Files Free 3D Laser Cut Files Free: Unleash Your Creativity

H1: Factors to Consider When Choosing a 3D Laser Cutting Machine Supplier

1. Reputation and Industry Experience

A supplier’s reputation within the industry is a testament to their reliability, quality of products, and customer service. Look for suppliers with a proven track record of success and positive customer testimonials.

2. Product Range and Customization

Suppliers should offer a wide range of 3D laser cutting machines to cater to different industry needs. They should also provide customization options to tailor machines to specific requirements.

1. Laser Power and Cutting Area

Laser power determines the thickness and materials that can be cut. The cutting area defines the maximum dimensions of the objects that can be processed.

2. Precision and Accuracy

3D laser cutting machines should deliver precise and accurate cuts, ensuring high-quality finished products. Evaluate the machine’s resolution, repeatability, and cutting tolerance.

3. Software Compatibility

Compatibility with industry-standard software is crucial for seamless integration with design and manufacturing workflows. Ensure the machine supports popular CAD/CAM programs.

4. Safety Features

Laser cutting machines must adhere to safety standards. Look for features such as enclosed workspaces, fume extraction systems, and emergency stop buttons.

5. Automation and Connectivity

Advanced machines offer automation capabilities, such as automatic loading and unloading, to increase productivity. Connectivity features, such as remote monitoring and data analytics, enable efficient machine management.

H3: Recommendations for Choosing the Right 3D Laser Cutting Machine Supplier

1. Research and Due Diligence

Thoroughly research potential suppliers, read customer reviews, and visit their facilities if possible. This due diligence will provide valuable insights into their capabilities and reliability.

2. Request Demonstrations

Request live demonstrations of the machines to witness their performance and capabilities firsthand. This will help you make an informed decision and identify potential issues.

3. Negotiate Contract Terms

Negotiate clear and detailed contract terms, including machine specifications, delivery timelines, payment terms, and warranty provisions. Ensure the contract aligns with your business requirements.

4. Seek Ongoing Support

Choose suppliers who prioritize ongoing support and customer satisfaction. This includes providing regular maintenance, software updates, and technical assistance.

Conclusion

Choosing the right 3D laser cutting machine supplier is essential for businesses to optimize their manufacturing processes. By considering the factors outlined above, evaluating key machine features, and following the recommendations provided, you can identify suppliers who can meet your specific needs and provide reliable, high-quality solutions.

FAQs

Q: What materials can 3D laser cutting machines cut?

A: 3D laser cutting machines can cut a wide range of materials, including metals (e.g., steel, aluminum), plastics (e.g., acrylic, polycarbonate), and wood.

Q: What is the difference between 3D and 2D laser cutting machines?

A: 3D laser cutting machines allow for cutting complex 3-dimensional shapes, while 2D machines are limited to cutting 2-dimensional profiles.

Q: How long does it take to deliver a 3D laser cutting machine?

A: Lead times vary depending on the supplier and machine specifications. It is important to inquire about delivery timelines and plan accordingly.

Q: What is the cost of a 3D laser cutting machine?

A: The cost varies based on the machine’s capabilities, features, and customization options. It is recommended to obtain quotes from multiple suppliers to compare prices and value for money.

Q: How can I maintain a 3D laser cutting machine?

A: Regular maintenance is essential for optimal performance. This includes cleaning the machine, replacing consumables, and performing software updates. It is recommended to follow the supplier’s maintenance guidelines.