3D Laser Metal Cutting Machine: A Comprehensive Guide

Introduction

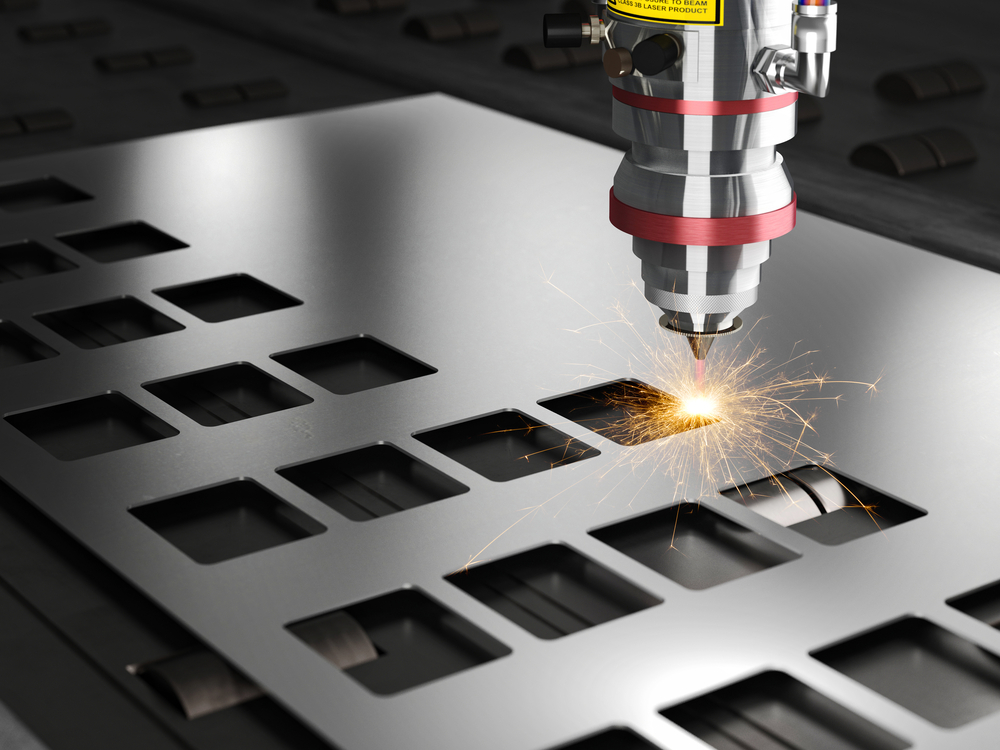

In the realm of metalworking, the advent of 3D laser cutting machines has revolutionized the industry. These machines offer unparalleled precision, efficiency, and versatility, enabling manufacturers to create intricate and complex metal components with unmatched accuracy. This article delves into the world of 3D laser metal cutting machines, exploring their principles, applications, advantages, and factors to consider when selecting one.

Table of Content

- 1 3D Laser Metal Cutting Machine: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Understanding 3D Laser Metal Cutting

- 1.3 H2: Principles of 3D Laser Metal Cutting

- 1.4 H3: Advantages of 3D Laser Metal Cutting

- 1.5 H1: Understanding 3D Laser Metal Cutting

- 1.6 H2: Principles of 3D Laser Metal Cutting

- 1.7 H2: Applications of 3D Laser Metal Cutting

- 1.8 H3: Factors to Consider When Selecting a 3D Laser Metal Cutting Machine

- 1.9 H2: Conclusion

- 1.10 FAQs

H1: Understanding 3D Laser Metal Cutting

H2: Principles of 3D Laser Metal Cutting

The process of 3D laser metal cutting involves several key principles:

- Laser Source: The machine generates a high-powered laser beam, typically from a fiber or CO2 laser source.

- Optics: A series of mirrors and lenses guide and focus the laser beam onto the workpiece.

- Motion System: A computer-controlled motion system moves the laser head along the desired cutting path, ensuring precise positioning and contouring.

- Gas Assist: Inert gases, such as nitrogen or argon, are often used to assist in the cutting process, removing debris and preventing oxidation.

H3: Advantages of 3D Laser Metal Cutting

Compared to traditional cutting methods, 3D laser metal cutting offers numerous advantages:

In the realm of metalworking, the advent of 3D laser cutting machines has revolutionized the industry. These machines offer unparalleled precision, efficiency, and versatility, enabling manufacturers to create intricate and complex metal components with unmatched accuracy. This article delves into the world of 3D laser metal cutting machines, exploring their principles, applications, advantages, and factors to consider when selecting one.

- 3d Puzzle Laser Cut Files 3D Puzzle Laser Cut Files: A Comprehensive Guide For Designers And Makers

- Laser Cut 3d Maze Laser Cut 3D Maze: A Labyrinth Of Intricate Design

- Laser Cutter Comparable To Glowforge Laser Cutter Comparable To Glowforge: A Comprehensive Guide

- 3d Crystal Laser Cutting Machine 3D Crystal Laser Cutting Machine: A Comprehensive Guide

- 3d House Laser Cutting 3D House Laser Cutting: Revolutionizing Residential Construction

H1: Understanding 3D Laser Metal Cutting

3D laser metal cutting is a transformative technology that utilizes a focused laser beam to cut and shape metal sheets in three dimensions. Unlike traditional 2D laser cutting, which operates on a flat plane, 3D laser cutting machines employ specialized optics and motion systems to direct the laser beam along complex contours, creating intricate shapes and structures.

H2: Principles of 3D Laser Metal Cutting

The process of 3D laser metal cutting involves several key principles:

- High Precision: The precise control of the laser beam enables cutting with exceptional accuracy and repeatability.

- Complex Shapes: 3D laser cutting machines can create intricate and complex shapes that are difficult or impossible to achieve with other methods.

- Speed and Efficiency: The high-powered laser beam cuts through metal rapidly, reducing production times and increasing productivity.

- Minimal Material Waste: The focused laser beam minimizes material waste, maximizing material utilization and reducing costs.

- Versatile Applications: 3D laser metal cutting machines are suitable for a wide range of materials, including steel, stainless steel, aluminum, and titanium.

- Aerospace: Cutting of complex aircraft components, such as brackets, panels, and honeycomb structures.

- Automotive: Fabrication of intricate parts for engines, transmission systems, and bodywork.

- Medical: Production of medical devices, implants, and surgical instruments.

- Electronics: Cutting of printed circuit boards (PCBs) and electronic components.

- Jewelry: Creation of intricate jewelry designs and custom pieces.

- Laser Power: The laser power determines the cutting speed and thickness of the materials that can be processed.

- Cutting Area: The size of the cutting area dictates the maximum dimensions of the workpiece that can be accommodated.

- Motion System: The accuracy and speed of the motion system are crucial for precise cutting and contouring.

- Software: The software controls the machine’s operation and determines the level of automation and user-friendliness.

- Cost: The investment cost, operating expenses, and maintenance costs should be evaluated based on the intended usage and budget.

H2: Applications of 3D Laser Metal Cutting

The applications of 3D laser metal cutting span a diverse range of industries, including:

H3: Factors to Consider When Selecting a 3D Laser Metal Cutting Machine

Choosing the right 3D laser metal cutting machine requires careful consideration of several factors:

H2: Conclusion

3D laser metal cutting machines have revolutionized the metalworking industry, enabling the creation of complex and intricate metal components with unmatched precision and efficiency. Their versatility, speed, and minimal material waste make them an ideal solution for a wide range of applications. When selecting a 3D laser metal cutting machine, it is essential to consider factors such as laser power, cutting area, motion system, software, and cost to ensure the optimal machine for the intended purpose.

FAQs

Q: What materials can 3D laser metal cutting machines process?

A: 3D laser metal cutting machines can process a wide range of materials, including steel, stainless steel, aluminum, titanium, and other metals.

Q: How thick can 3D laser metal cutting machines cut?

A: The cutting thickness depends on the laser power and the material being cut. Typically, 3D laser metal cutting machines can cut materials up to several millimeters thick.

Q: What is the accuracy of 3D laser metal cutting machines?

A: 3D laser metal cutting machines offer high precision, with tolerances typically in the range of +/-0.05mm.

Q: Are 3D laser metal cutting machines easy to operate?

A: The ease of operation depends on the specific machine and software. Modern 3D laser metal cutting machines often feature user-friendly interfaces and automated functions, making them accessible to operators with varying levels of experience.