Laser Cutting 3D Objects: A Comprehensive Guide

Introduction

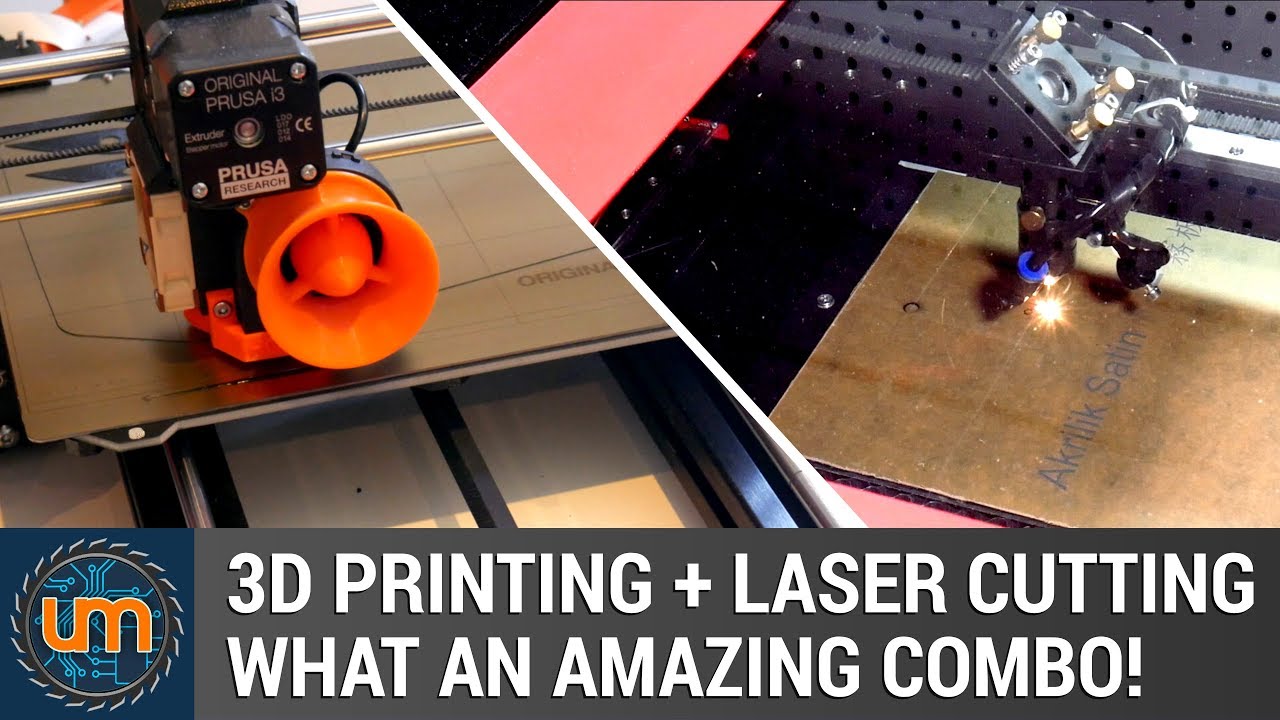

Laser cutting has revolutionized the manufacturing industry, enabling the creation of intricate and complex 3D objects with unmatched precision. This technology offers numerous advantages over traditional cutting methods, including increased speed, accuracy, and versatility. In this article, we will explore the fundamentals of laser cutting 3D objects, discussing the process, materials, applications, and factors to consider when selecting a laser cutting system.

Table of Content

- 1 Laser Cutting 3D Objects: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: The Laser Cutting Process

- 1.3 H1: Materials Suitable for Laser Cutting

- 1.4 H1: The Laser Cutting Process

- 1.5 H1: Applications of Laser Cutting 3D Objects

- 1.6 H1: Factors to Consider When Selecting a Laser Cutting System

- 1.7 Conclusion

- 1.8 FAQs

H1: The Laser Cutting Process

Laser cutting involves directing a high-powered laser beam onto a material, causing it to melt, vaporize, or sublime. The laser is typically focused through a lens to create a narrow, concentrated beam, which is then guided by a computer-controlled system. The movement of the laser beam is synchronized with the material’s movement, resulting in precise cuts along predetermined paths.

H3: Types of Laser Cutting

There are several types of laser cutting processes, each with its own advantages and applications:

- CO2 Laser Cutting: This is the most common type of laser cutting, using a carbon dioxide laser to produce high-quality cuts in a wide range of materials, including metals, plastics, and wood.

- Fiber Laser Cutting: This technology utilizes a fiber laser, which offers higher power and efficiency than CO2 lasers. It is particularly suitable for cutting thin metals and reflective materials.

- Excimer Laser Cutting: This process uses an excimer laser to create precise cuts in thin materials, such as polymers and ceramics.

H1: Materials Suitable for Laser Cutting

H2: Common Materials

Laser cutting has revolutionized the manufacturing industry, enabling the creation of intricate and complex 3D objects with unmatched precision. This technology offers numerous advantages over traditional cutting methods, including increased speed, accuracy, and versatility. In this article, we will explore the fundamentals of laser cutting 3D objects, discussing the process, materials, applications, and factors to consider when selecting a laser cutting system.

- 3d Laser Cutting Melbourne 3D Laser Cutting Melbourne: The Ultimate Guide To Precision And Efficiency

- Sculpteo Laser Cutting Sculpteo Laser Cutting: A Comprehensive Guide To Precision Manufacturing

- 3d Laser Cut Wood 3D Laser Cut Wood: Unlocking Intricate Designs And Precision Craftsmanship

- 3d Model Laser Cutting File 3D Model Laser Cutting File: A Comprehensive Guide

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

H1: The Laser Cutting Process

H2: How Laser Cutting Works

Laser cutting involves directing a high-powered laser beam onto a material, causing it to melt, vaporize, or sublime. The laser is typically focused through a lens to create a narrow, concentrated beam, which is then guided by a computer-controlled system. The movement of the laser beam is synchronized with the material’s movement, resulting in precise cuts along predetermined paths.

H3: Types of Laser Cutting

There are several types of laser cutting processes, each with its own advantages and applications:

Laser cutting can be performed on a variety of materials, including:

- Metals: Steel, stainless steel, aluminum, copper, and titanium

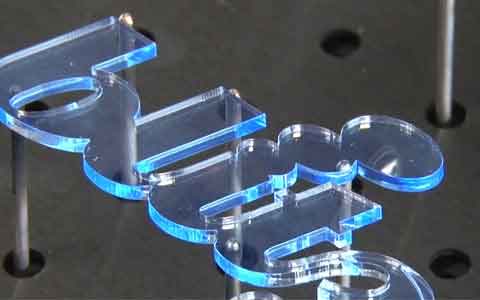

- Plastics: Acrylic, polycarbonate, polyethylene, and polypropylene

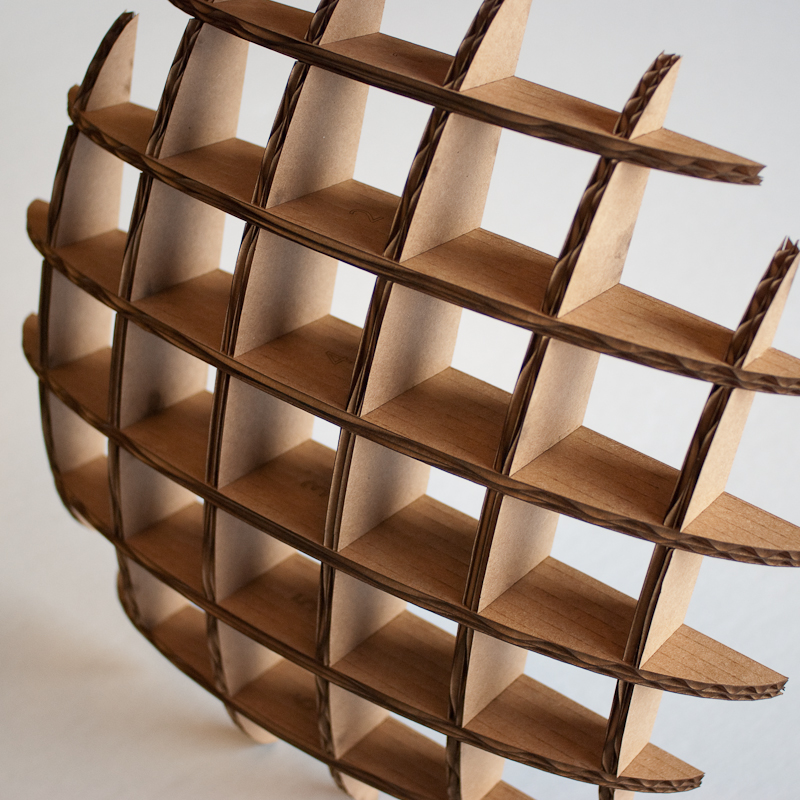

- Wood: Plywood, MDF, and hardwoods

- Ceramics: Glass, tiles, and marble

H3: Material Considerations

The suitability of a material for laser cutting depends on several factors:

- Melting Point: The material should have a melting point below the temperature generated by the laser beam.

- Thermal Conductivity: Materials with low thermal conductivity are more suitable for laser cutting, as they prevent heat from spreading and affecting surrounding areas.

- Chemical Composition: Some materials, such as certain alloys, may react with the laser beam, producing undesirable effects.

H1: Applications of Laser Cutting 3D Objects

H2: Industrial Applications

Laser cutting is widely used in various industries, including:

- Automotive: Cutting and shaping metal components for vehicles

- Aerospace: Manufacturing aircraft parts and components

- Medical: Creating surgical instruments, implants, and prosthetics

- Electronics: Producing printed circuit boards and electronic components

H3: Artistic and Hobbyist Applications

Beyond industrial applications, laser cutting has also gained popularity in the arts and crafts community:

- Jewelry Making: Cutting intricate designs in precious metals

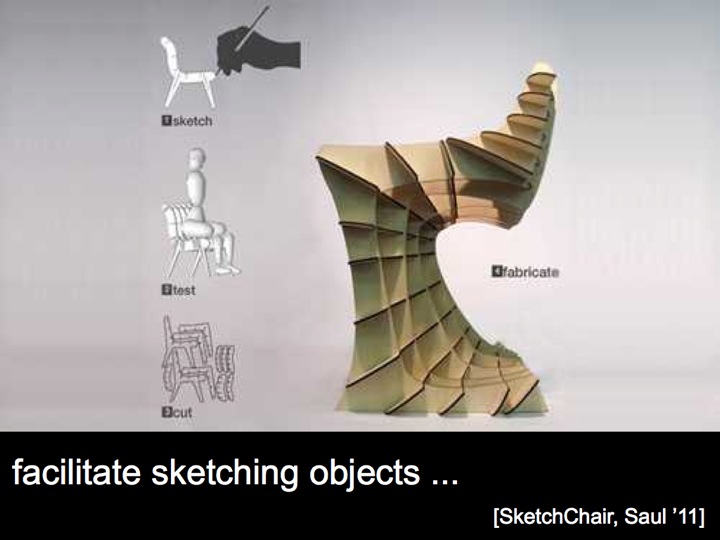

- Model Building: Creating detailed models of buildings, vehicles, and other objects

- Home Decor: Producing decorative items, such as lamps, wall art, and furniture

H1: Factors to Consider When Selecting a Laser Cutting System

H2: Laser Power

The power of the laser beam determines the thickness and type of materials that can be cut. Higher power lasers are capable of cutting thicker materials and provide faster cutting speeds.

H3: Bed Size

The bed size of the laser cutter determines the maximum size of objects that can be cut. Choose a bed size that accommodates your project requirements.

H4: Automation Features

Automated features, such as material loading and unloading systems, can increase productivity and reduce labor costs.

H5: Software Compatibility

Ensure that the laser cutting software is compatible with your design software and can generate appropriate cutting paths.

Conclusion

Laser cutting 3D objects offers numerous advantages and applications across various industries and creative endeavors. By understanding the process, materials, and factors involved in selecting a laser cutting system, you can harness this technology to create intricate and precise 3D objects. With its versatility and precision, laser cutting continues to revolutionize manufacturing and empower artists and hobbyists alike.

FAQs

Q: What is the minimum thickness of material that can be laser cut?

A: The minimum thickness depends on the laser power and material properties. Typically, CO2 lasers can cut materials as thin as 0.004 inches, while fiber lasers can cut thinner materials.

Q: Can laser cutting be used to create complex 3D shapes?

A: Yes, laser cutting can be used to create complex 3D shapes by combining multiple cuts and using specialized software to generate the cutting paths.

Q: Is laser cutting safe?

A: Laser cutting can be hazardous if proper safety precautions are not followed. This includes wearing appropriate protective gear, ensuring proper ventilation, and following manufacturer’s safety guidelines.