3D Model of Laser Cutting: A Comprehensive Guide

Introduction

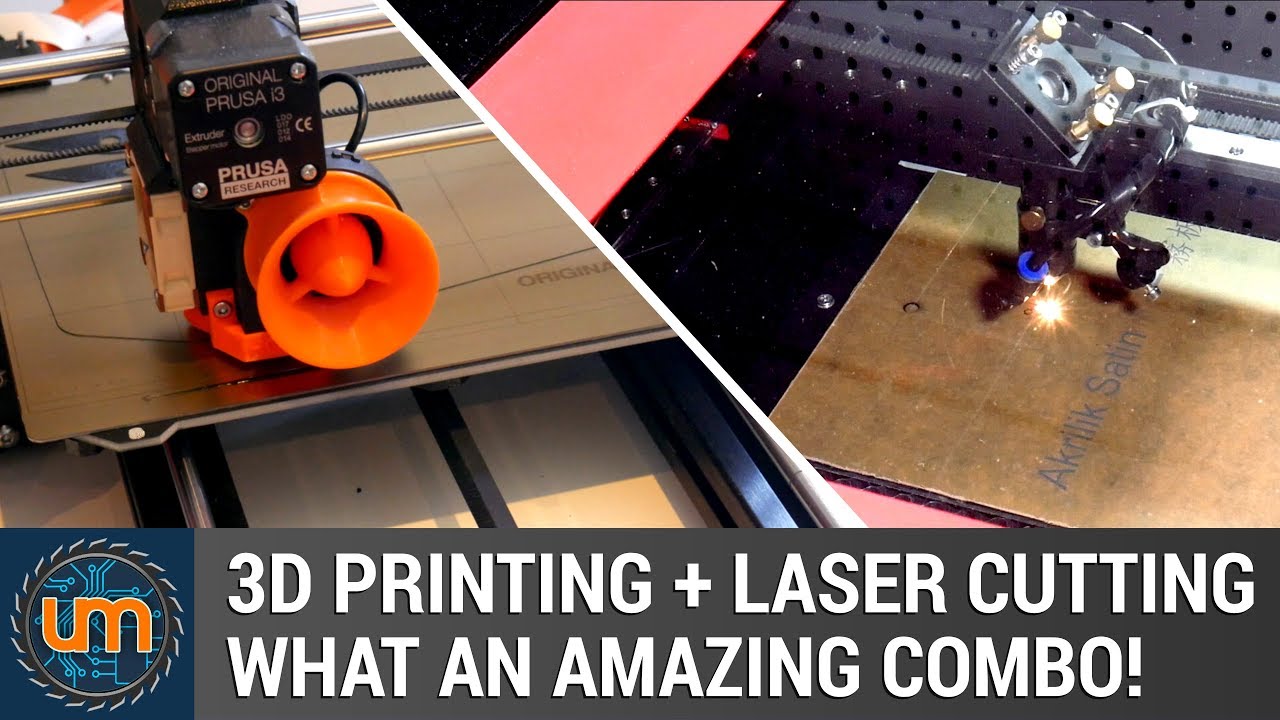

Laser cutting is a versatile manufacturing process that utilizes a high-powered laser to precisely cut and shape materials. With the advent of 3D modeling software, it is now possible to create complex 3D models and use them to guide laser cutting machines, resulting in highly accurate and intricate cuts. This article delves into the world of 3D modeling for laser cutting, providing a comprehensive guide to its benefits, applications, and technical considerations.

Table of Content

Benefits of Using 3D Models for Laser Cutting

3D models enable precise control over the laser cutting process, ensuring accurate cuts with minimal deviations. The digital model provides detailed information about the shape, dimensions, and tolerances of the desired cut, eliminating human error and reducing scrap rates.

2. Complex Geometries:

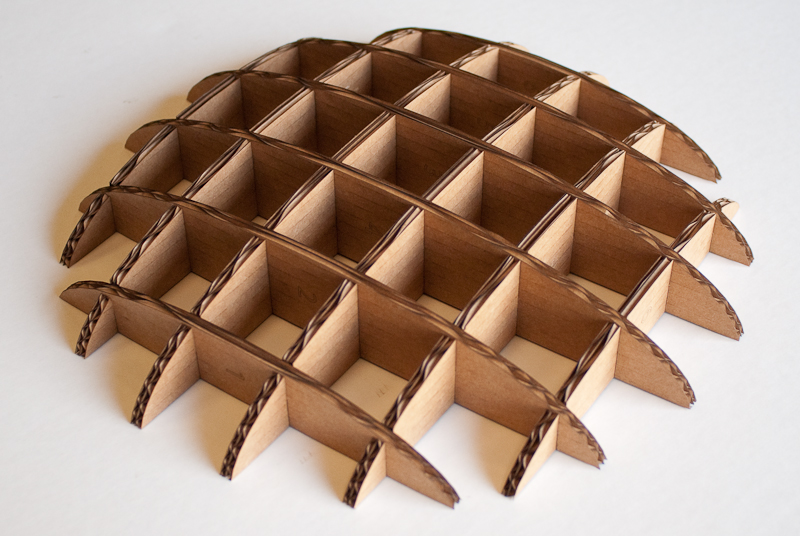

3D modeling allows for the creation of intricate and complex geometries that would be difficult or impossible to achieve with traditional cutting methods. It empowers designers to push the boundaries of innovation and create unique and functional products.

3. Design Optimization:

3D models facilitate design optimization by enabling virtual prototyping and simulation. Engineers can test and refine designs digitally, reducing the need for physical prototypes and minimizing production costs.

4. Material Efficiency:

3D modeling enables nesting of multiple parts within the material, maximizing material utilization and minimizing waste. This reduces material costs and promotes sustainable manufacturing practices.

5. Increased Productivity:

Automated laser cutting machines guided by 3D models can operate 24/7, increasing production speed and efficiency. The digital workflow eliminates manual setup and programming, freeing up operators for other tasks.

Applications of 3D Model Laser Cutting

Laser cutting is a versatile manufacturing process that utilizes a high-powered laser to precisely cut and shape materials. With the advent of 3D modeling software, it is now possible to create complex 3D models and use them to guide laser cutting machines, resulting in highly accurate and intricate cuts. This article delves into the world of 3D modeling for laser cutting, providing a comprehensive guide to its benefits, applications, and technical considerations.

- Laser Cutting 3d Objects Laser Cutting 3D Objects: A Comprehensive Guide

- 3d Laser Cutting Acrylic 3D Laser Cutting Acrylic: A Comprehensive Guide

- 3d Laser Cut House 3D Laser Cut House: A Revolutionary Approach To Modern Architecture

- Laser Cut 3d Rose Laser Cut 3D Rose: A Guide To Intricate And Stunning Creations

- Laser Cut 3d Puzzle Free Download Laser Cut 3D Puzzle: Free Download And Assembly Guide

Benefits of Using 3D Models for Laser Cutting

1. Precision and Accuracy:

3D models enable precise control over the laser cutting process, ensuring accurate cuts with minimal deviations. The digital model provides detailed information about the shape, dimensions, and tolerances of the desired cut, eliminating human error and reducing scrap rates.

2. Complex Geometries:

3D modeling allows for the creation of intricate and complex geometries that would be difficult or impossible to achieve with traditional cutting methods. It empowers designers to push the boundaries of innovation and create unique and functional products.

1. Aerospace:

Laser cutting of 3D models is used to create lightweight and durable aircraft components, such as structural parts, panels, and engine mounts.

2. Automotive:

The automotive industry utilizes 3D model laser cutting for intricate body panels, exhaust systems, and interior components, enhancing aesthetics and performance.

3. Medical:

Medical devices and implants are often manufactured using laser cutting of 3D models, ensuring precision and biocompatibility.

4. Architecture:

Laser cutting of 3D models enables the creation of decorative and functional architectural elements, such as metal cladding, sculptures, and custom lighting fixtures.

5. Consumer Products:

3D model laser cutting finds applications in various consumer products, including jewelry, electronics, and household appliances, offering unique designs and customization options.

Technical Considerations for 3D Model Laser Cutting

1. Software Compatibility:

The 3D modeling software used should be compatible with the laser cutting machine’s software to ensure seamless data transfer and accurate cutting.

2. File Formats:

The 3D model file should be exported in a format supported by the laser cutting machine, such as DXF, DWG, or STL.

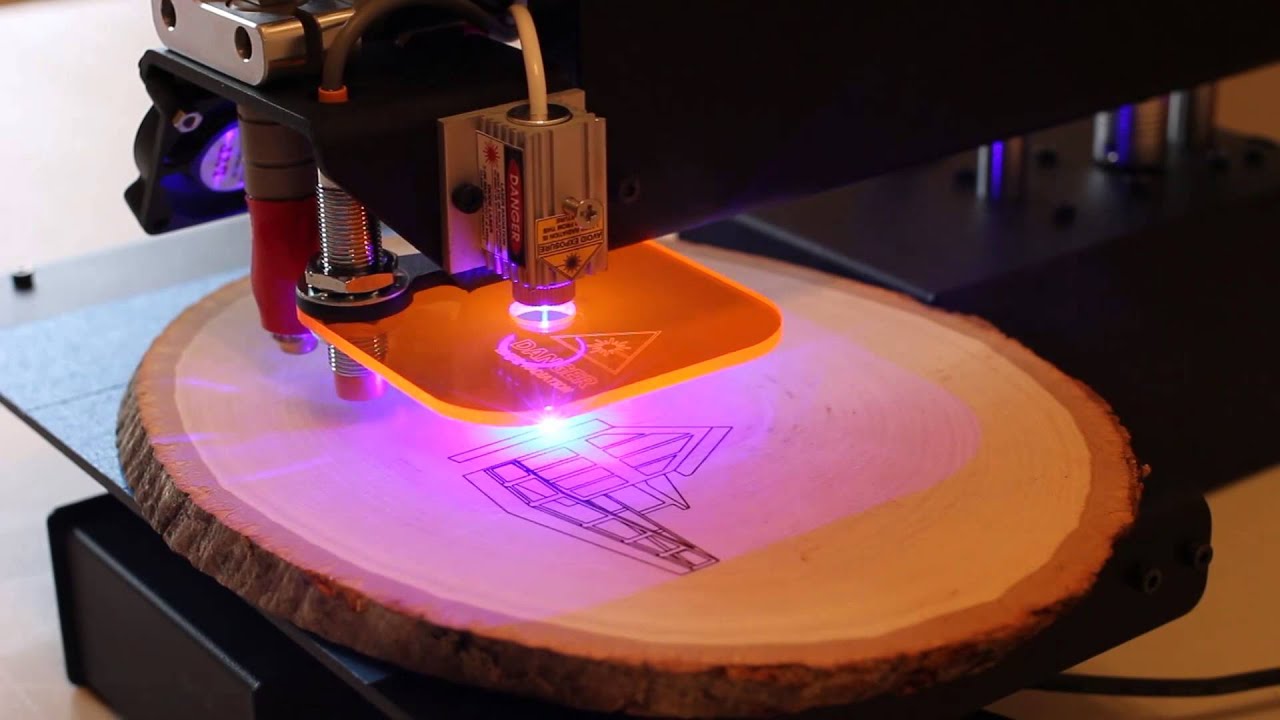

3. Laser Parameters:

The laser cutting machine’s parameters, such as power, speed, and focal length, must be optimized for the specific material and thickness being cut.

4. Material Properties:

The properties of the material being cut, including its reflectivity, thermal conductivity, and melting point, influence the laser cutting process.

5. Safety Precautions:

Laser cutting operations require proper safety measures, including eye protection, ventilation, and fire suppression systems.

Conclusion

3D modeling for laser cutting offers numerous advantages, enabling the creation of complex geometries, maximizing precision and accuracy, optimizing material utilization, and increasing productivity. It has found widespread applications in various industries, including aerospace, automotive, medical, architecture, and consumer products. By understanding the technical considerations and leveraging the benefits of 3D modeling, manufacturers can unlock the full potential of laser cutting technology and drive innovation in their respective fields.

FAQs

1. What types of materials can be cut using 3D model laser cutting?

A wide range of materials can be cut using laser cutting, including metals, plastics, wood, and ceramics.

2. What is the maximum thickness that can be cut using 3D model laser cutting?

The maximum thickness that can be cut depends on the laser power, material type, and desired cut quality.

3. How does 3D model laser cutting differ from traditional laser cutting?

Traditional laser cutting uses 2D drawings, while 3D model laser cutting utilizes 3D models, allowing for more complex and intricate cuts.

4. What are the benefits of using 3D modeling software for laser cutting?

3D modeling software enables precise design, virtual prototyping, and optimization of the cutting process, resulting in improved accuracy, efficiency, and cost savings.

5. What safety precautions should be taken when using 3D model laser cutting?

Proper safety precautions include eye protection, ventilation, fire suppression systems, and adherence to manufacturer guidelines.

_Ha2aI1A.jpg)